Planetary speed reducer specially for continuous casting

A planetary reducer and continuous casting technology, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of limiting the bearing capacity of the reducer, and the transmission ratio cannot be reasonably matched, so as to achieve weight reduction, Bears an even effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

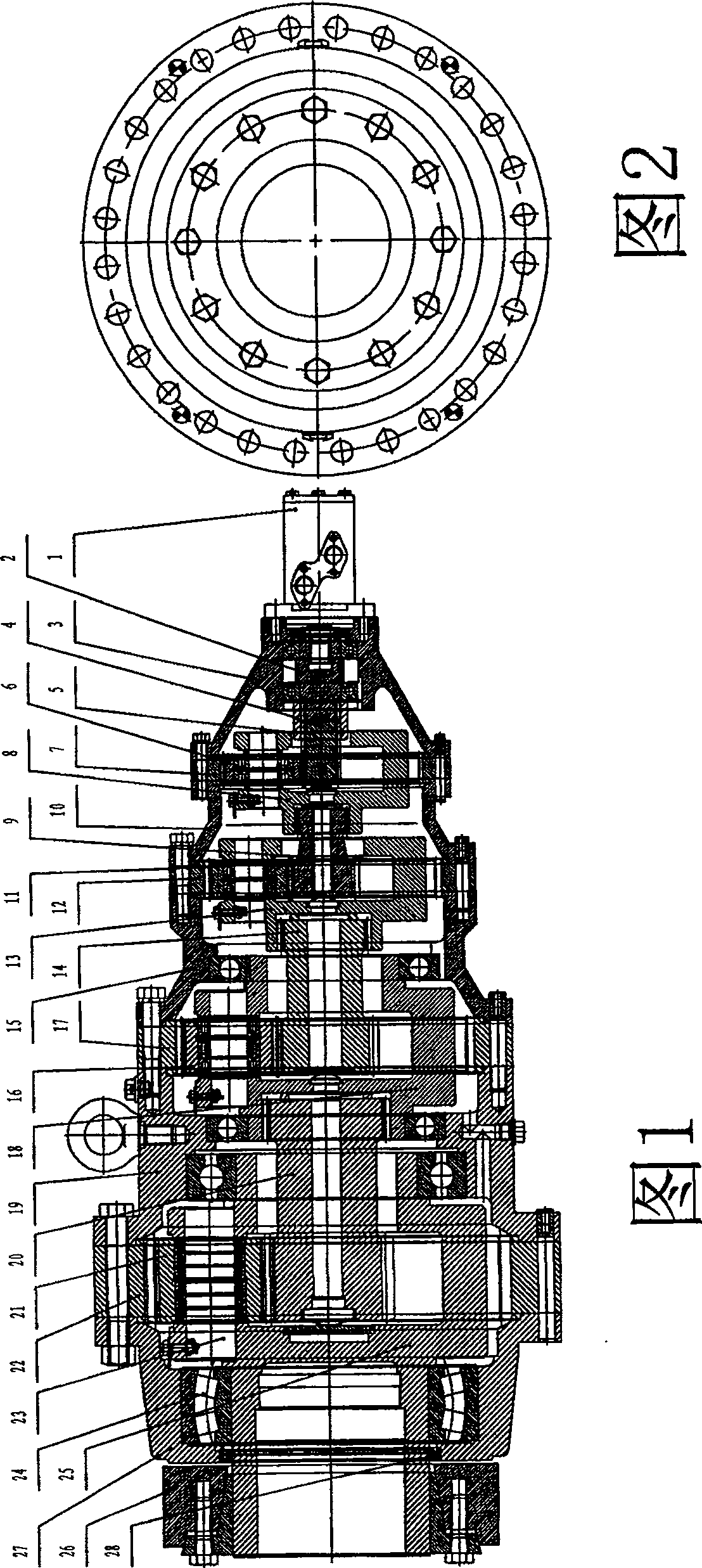

[0015] As shown in Figure 1 and Figure 2, 1. Hydraulic motor, 2. Input shaft, 3. Front body, 4. Internal gear sleeve, 5. First-stage sun gear, 6. First-stage planetary gear, 7. First-stage Internal ring gear, 8. First-stage planet carrier, 9. Second-stage sun gear, 10. First middle body, 11. Second-stage planetary gear, 12. Second-stage internal ring gear, 13. Second-stage planet frame, 14, the third stage sun gear, 15, the second middle body, 16, the third stage planetary gear, 17, the third stage ring gear, 18, the third stage planet carrier, 19, the third middle body, 20 , fourth-stage sun gear, 21, fourth-stage planetary gear, 22, fourth-stage ring gear, 23, planetary shaft, 24, bearing, 25, fourth-stage planet carrier, 26, expansion sleeve, 27, rear body , 28, oil seal.

[0016] In a specific embodiment of the present invention, the spe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap