Device for operating on circuit substrate

A circuit substrate and equipment technology, applied in the direction of printed circuit, printed circuit manufacturing, electrical components, etc., to achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

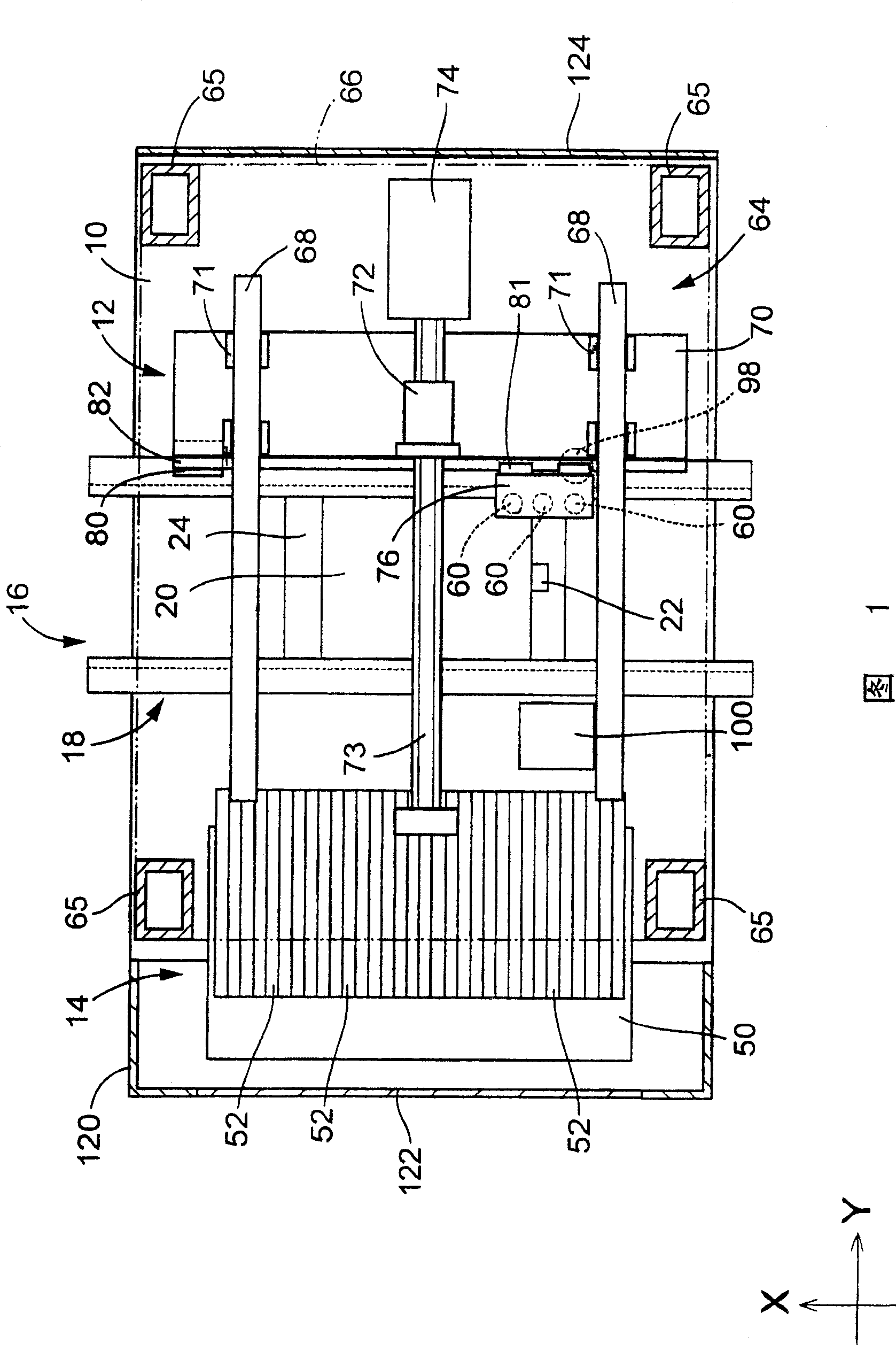

[0052] Embodiments of the present invention applied to an electronic component mounting device as an execution device operating on a circuit substrate will be described in detail below with reference to the drawings. An electronic component is an electrical component, and a corresponding electronic component mounting device is an electrical component mounting device.

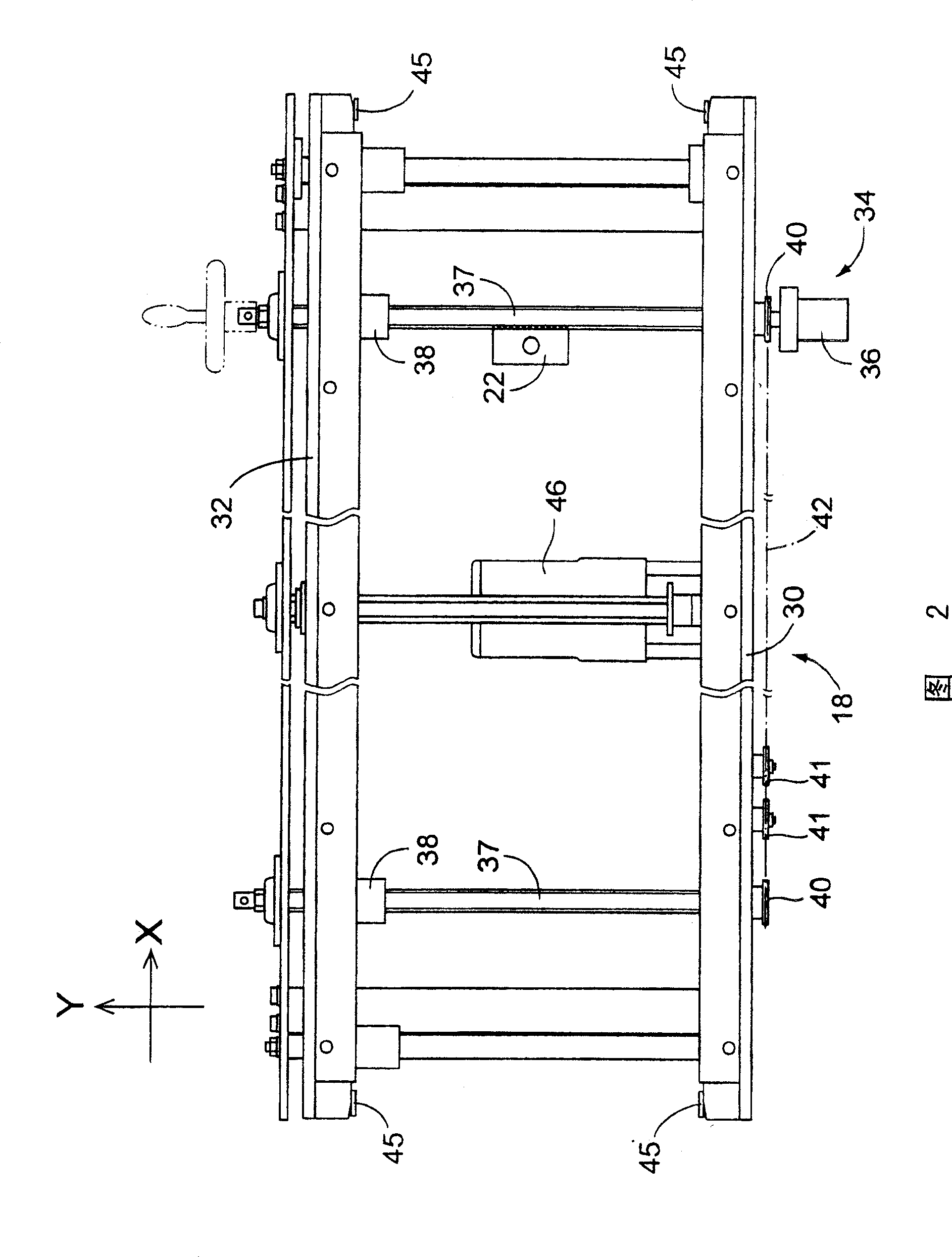

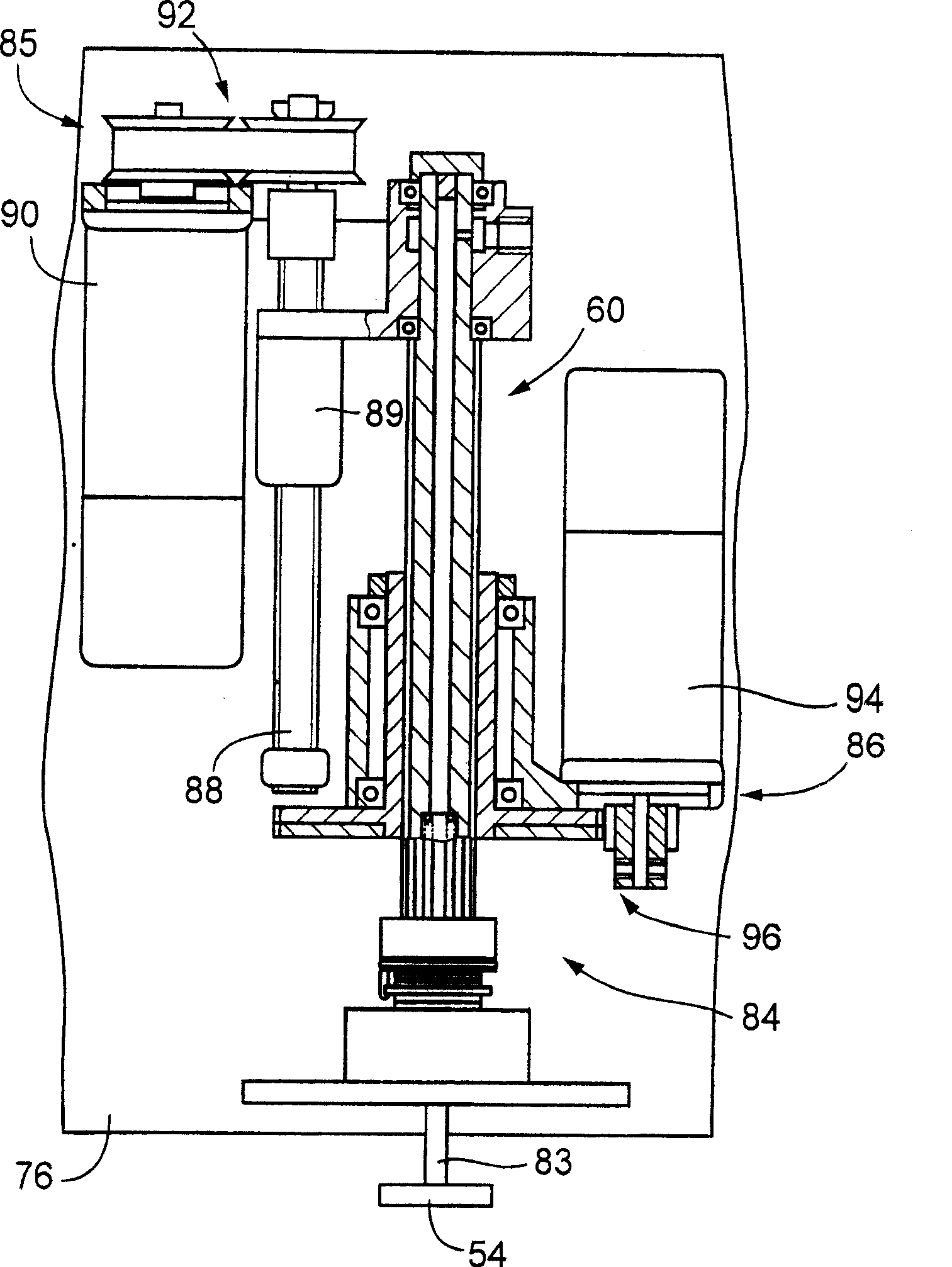

[0053] In FIG. 1, reference numeral 10 denotes the bottom of the electronic component mounting apparatus. At the bottom 10, a component mounting device 12, a component supply device 14, and a printed wiring board conveying device 16 are provided. The printed wiring board conveyor 16 includes a printed wiring board conveyor 18 as a circuit substrate conveyor that extends along the X-axis direction indicated by an arrow in FIG. 1 and conveys a printed wiring board as a circuit substrate. 20. The conveying device 16 also includes a stop device 22 that stops and positions the printed wiring board 20 conveyed by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com