Tap

A faucet and faucet technology, applied in the field of faucets, can solve the problems of time-consuming, inability to use plastic materials, complicated operation, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

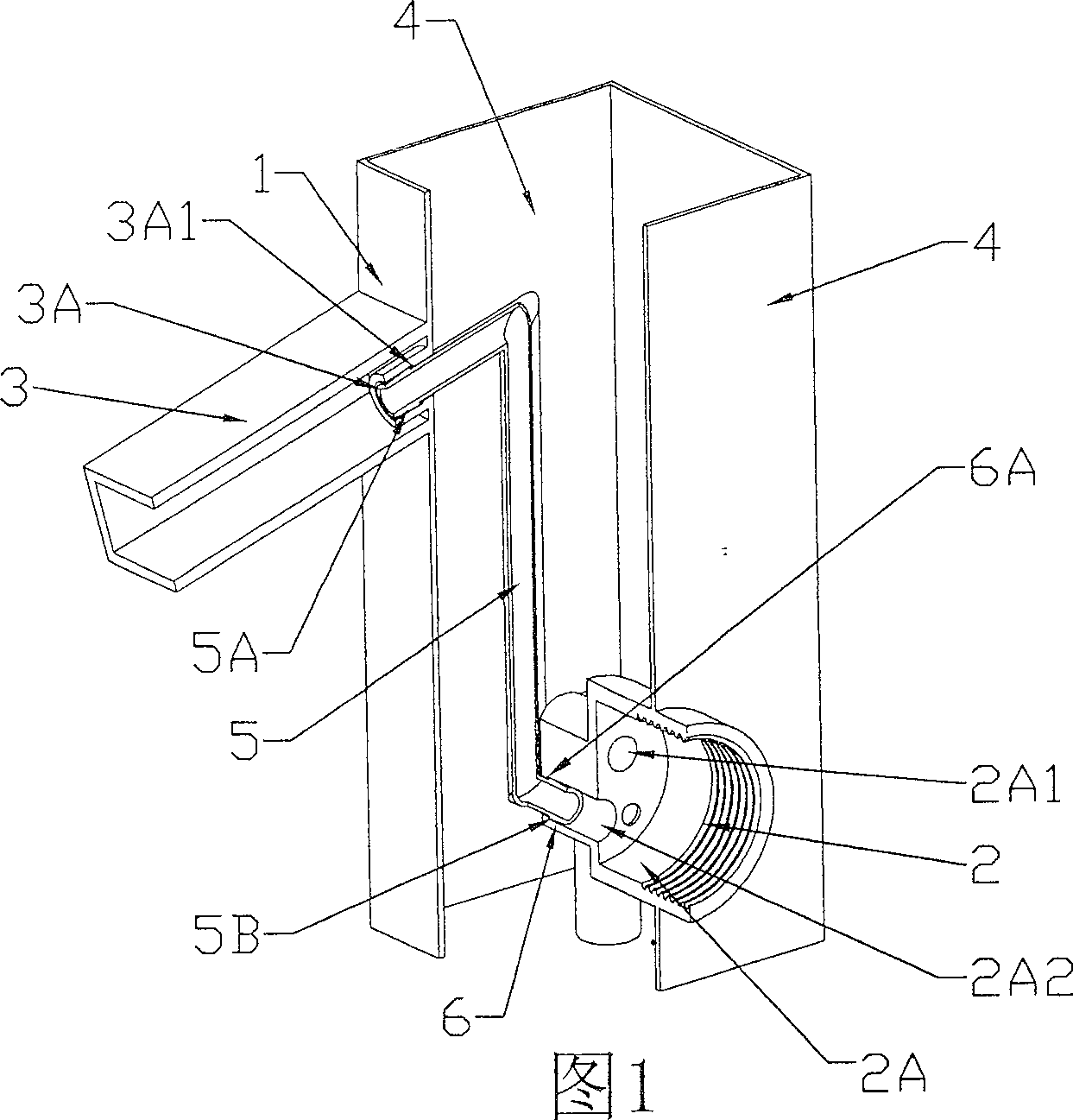

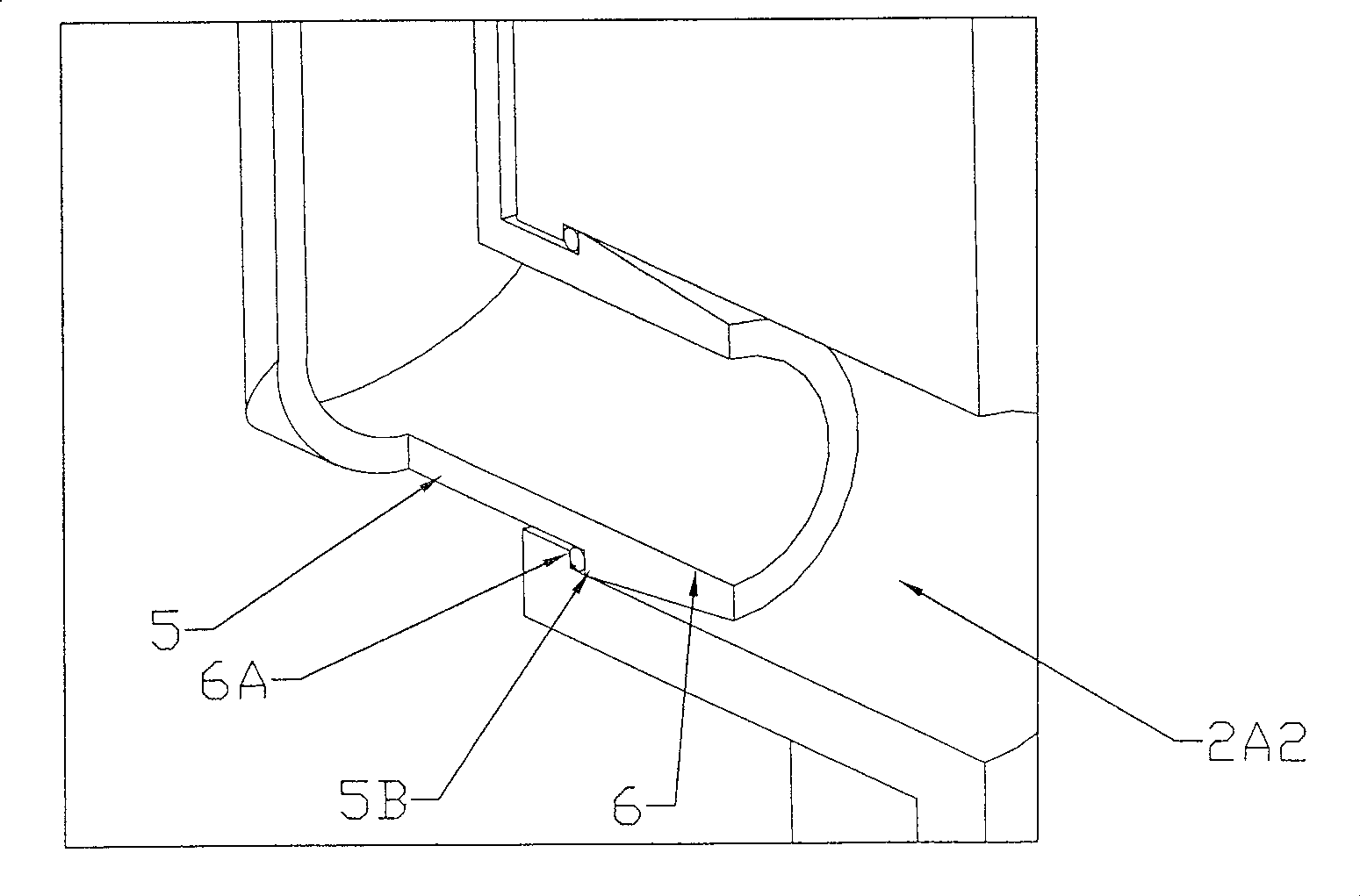

[0010] As shown in Figure 1, the faucet provided by the present invention includes a main faucet housing 1, the main faucet housing 1 includes a valve seat 2, a water outlet pipe 3, and a casing 4, a valve core assembly is arranged inside the valve seat 2, and the main faucet housing 1 An adjustment handle is also provided on the valve seat 2, and the bottom end of the spool placement chamber 2A on the valve seat 2 has a water inlet hole 2A1 and a water outlet hole 2A2, and the outlet pipe 3 is provided with a first plug port 3A inside the main casing 1 of the faucet. , the water outlet hole 2A2 is provided with a second plug port 6 inside the faucet main casing 1, and the faucet main casing 1 is also equipped with a plug-in fitting 5, the plug-in fitting 5 is a hose or a plastic pipe with certain elasticity, and the plug The two ends of the connection piece 5 are plugged into the first insertion port 3A and the second insertion port 6 respectively, and the insertion connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com