a wig stand

A wig and horizontal plate technology, applied in the field of wig brackets, can solve the problems of waste, fixed height, affecting the use effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

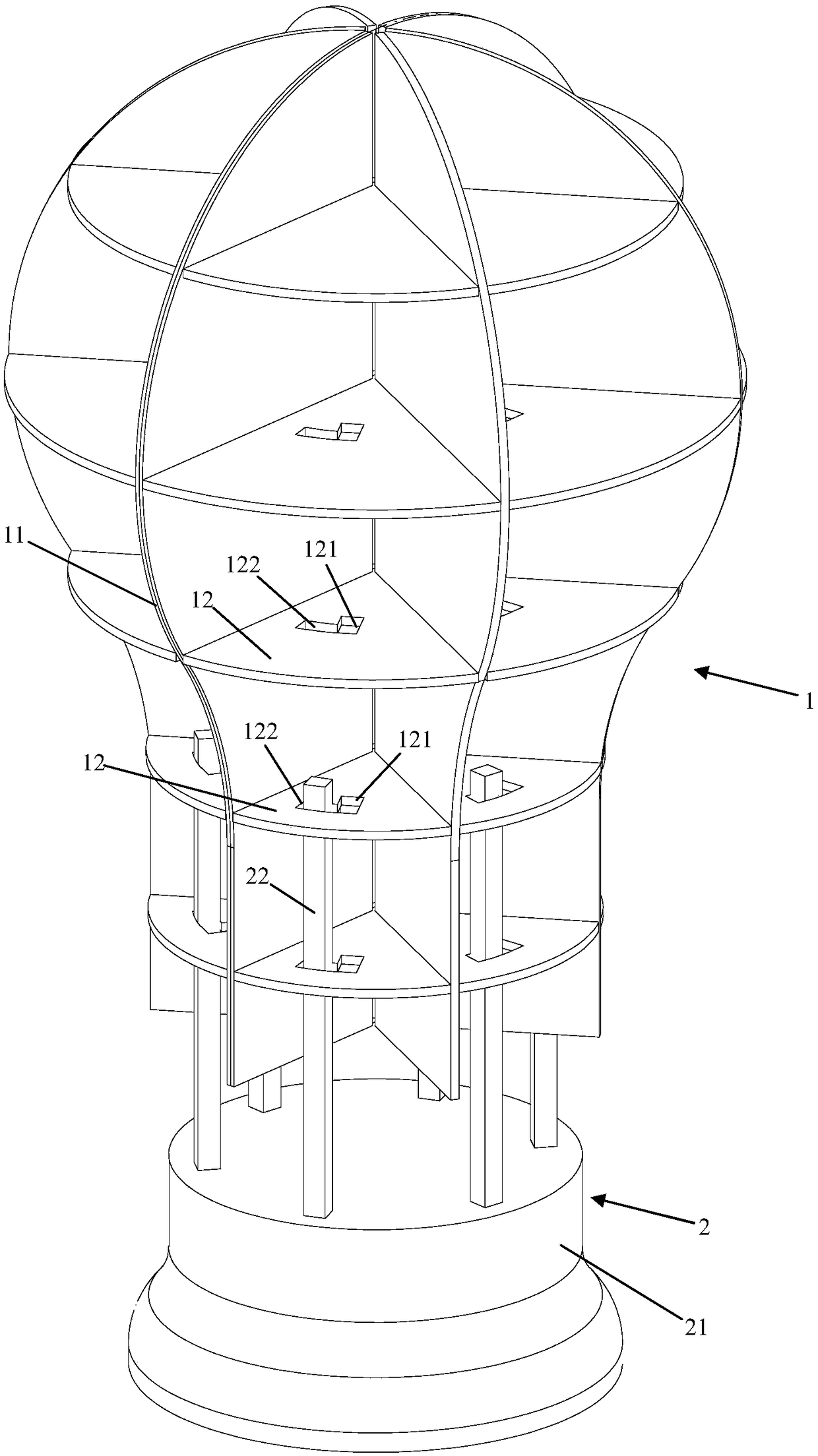

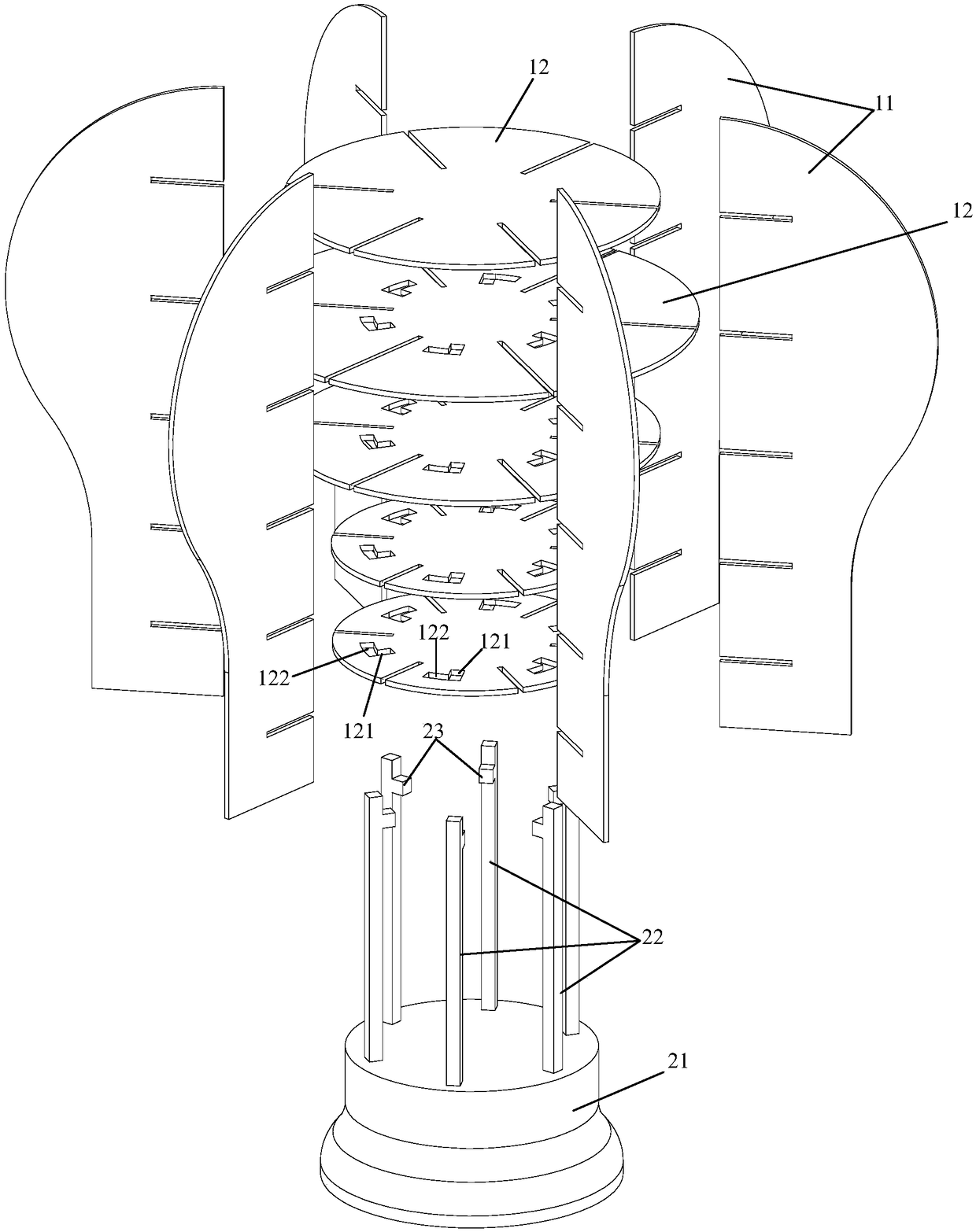

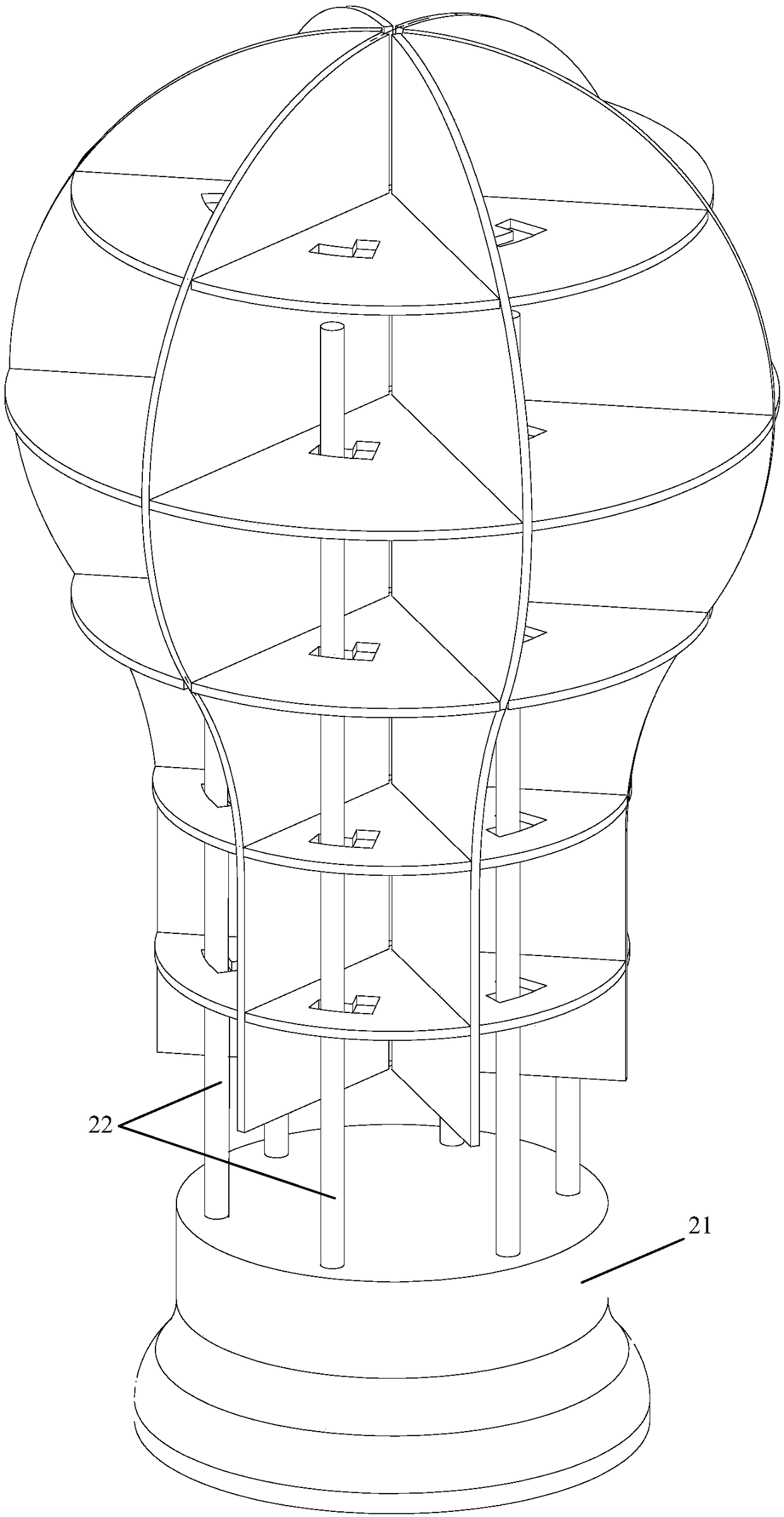

[0013] Such as figure 1 , 2 As shown, the first embodiment provides a wig bracket, including a first part 1 and a second part 2, the first part 1 includes six vertical plates 11 and five circular horizontal plates 12, and the five horizontal plates The plates 12 are coaxially arranged, and the six vertical plates 11 are evenly distributed in the circumferential direction of the five horizontal plates 12, and each of the vertical plates 11 is respectively inserted into the five horizontal plates 12; The second part 2 includes a base 21, six vertical support rods 22 arranged on the upper end surface of the base 21, and the upper inner side of each of the support rods 22 ("inside" and "radially inner" in the present invention) Refers to the radial inner direction of the horizontal plate, "radial outer" means the radial outer side of the horizontal plate) is provided with a support block 23 protruding from the side wall of the support rod 22; in each of the horizontal plates 12 ...

Embodiment 2

[0018] As shown in the figure, the difference between the second embodiment and the first embodiment is that the support rod 22 is a cylinder made of transparent resin, and an ultraviolet lamp (not shown in the figure) is vertically arranged in the cylinder. out).

[0019] Through the above structure, when the wig is placed on the bracket, the ultraviolet lamp can be turned on to sterilize the wig, so as to ensure that the wig is clean and sterile, healthy and safe; the support rod can not only adjust the height, but also It is also possible to place an ultraviolet lamp to sterilize and disinfect the wig from the inside to the outside at close range, and there will be no dead angle for disinfection inside the wig.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com