A refrigerator door body frame assembly

A refrigerator door and frame technology, which is applied to household refrigeration devices, lighting and heating equipment, household appliances, etc., can solve the problems of complex connection structure and assembly process, and achieve the effects of simple and convenient installation and rust prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

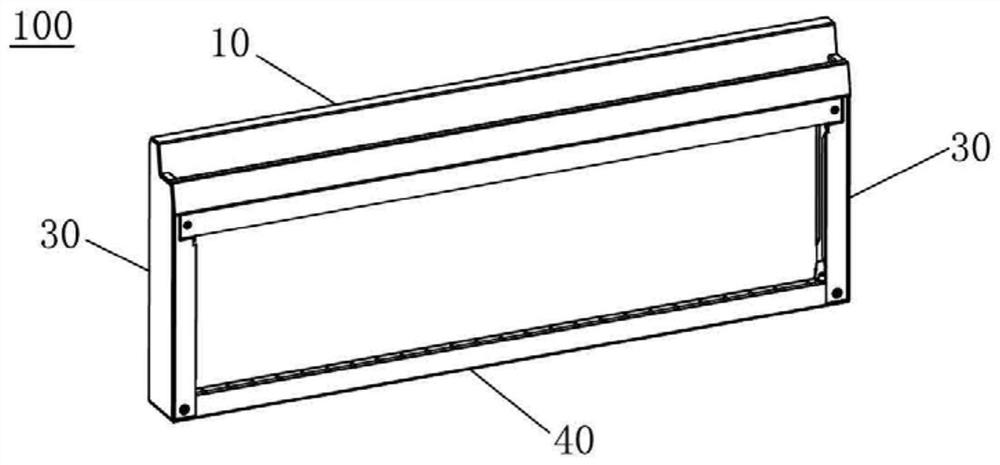

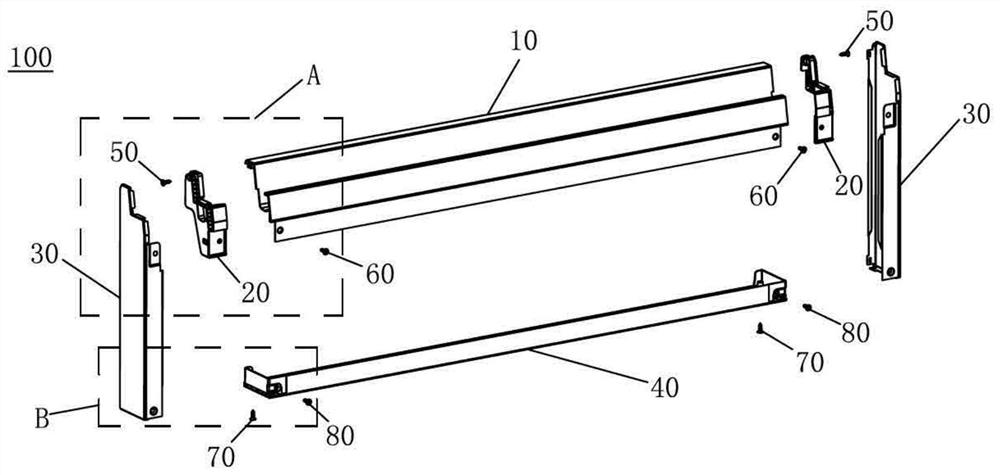

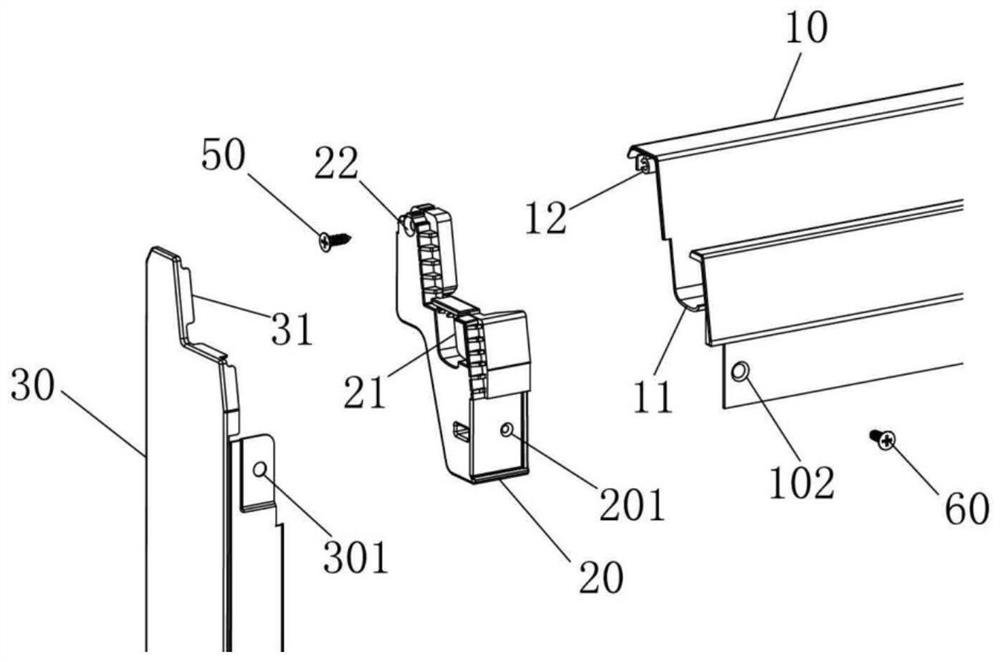

[0040] figure 1 It is a schematic structural diagram of a refrigerator door frame assembly according to an embodiment of the present invention. figure 2 It is an exploded schematic diagram of a refrigerator door frame assembly according to an embodiment of the present invention Figure 5 It is an exploded schematic diagram of the connection of the handle molding, the molding connector and the sheet metal molding according to an embodiment of the present invention. Such as figure 1 As shown, the present embodiment provides a refrigerator door frame assembly 100, which is a left-right symmetrical piece, and generally may include a handle molding 10 and a molding connecting piece 20 (see figure 2 ), the sheet metal molding 30 and the injection molding 40. The handle molding 10 extends in the width direction of the refrigerator. The decorative strip connector 20 is connected to one end of the handle decorative strip 10, and a first card slot 101 is formed between the decorative st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com