Wire rod plugging structure

A plug-in structure and wire technology, applied in the direction of fixed/insulated contact components, connections, contact parts, etc., can solve the problems of poor conduction, narrow width, small spacing, etc., and achieve the effect of simple operation, labor saving, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

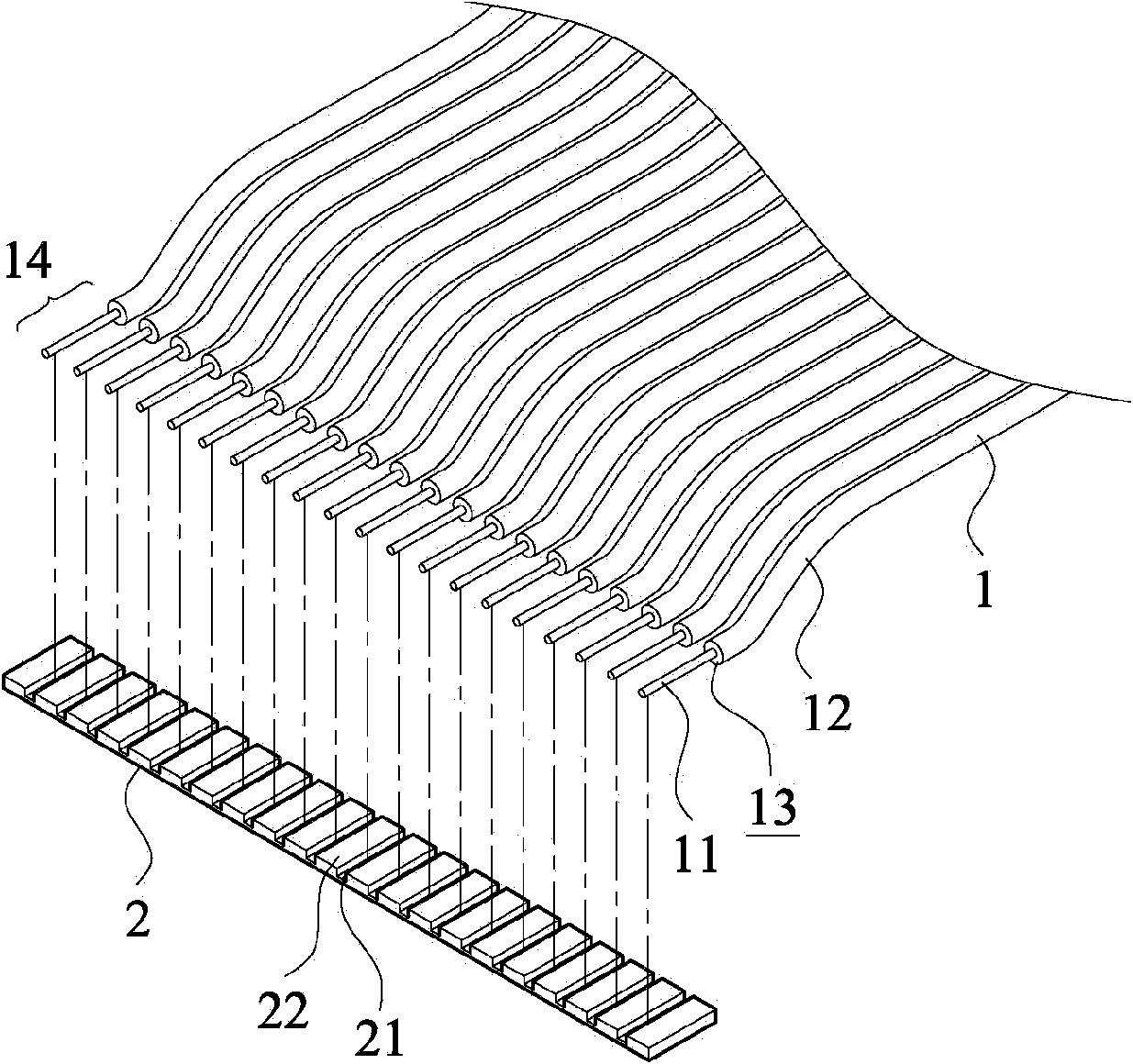

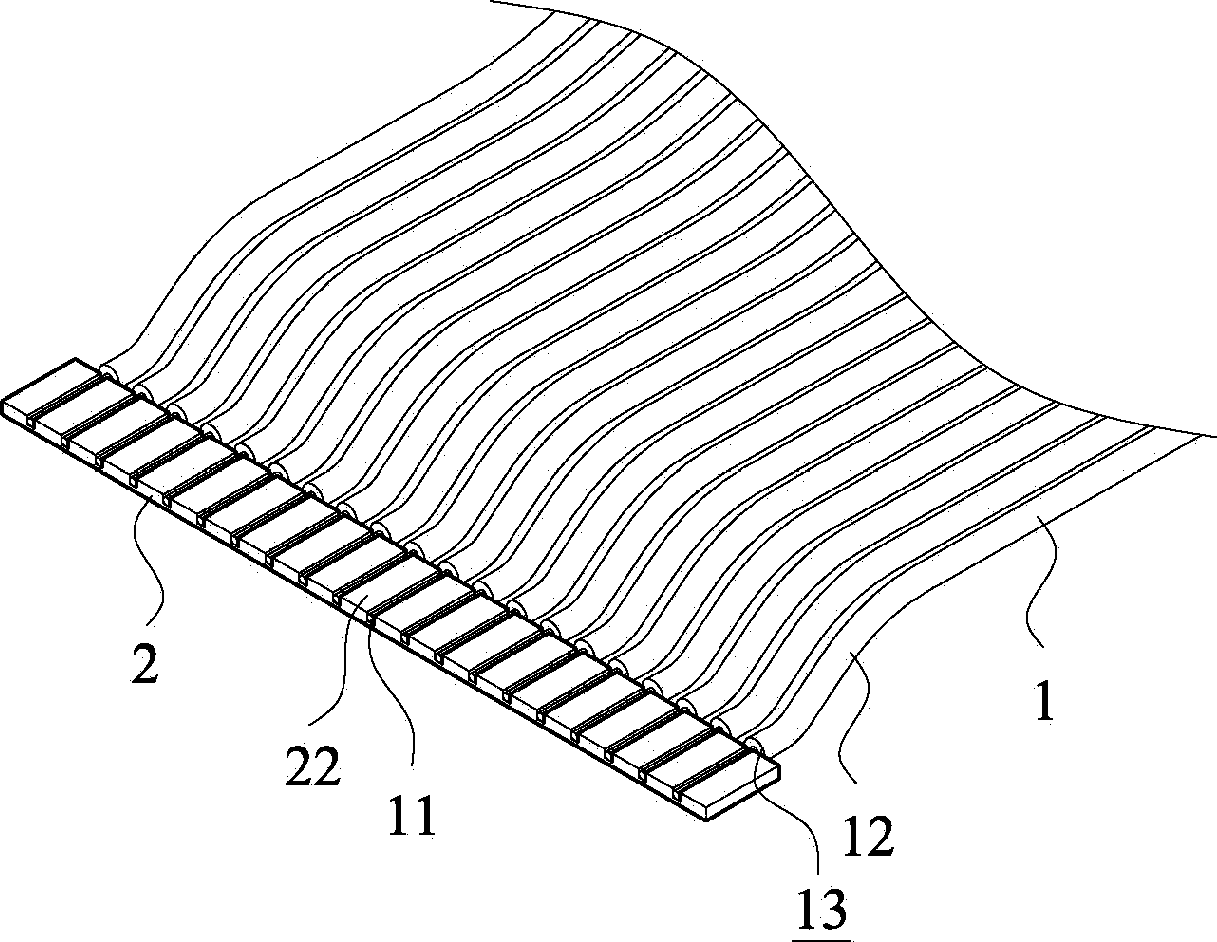

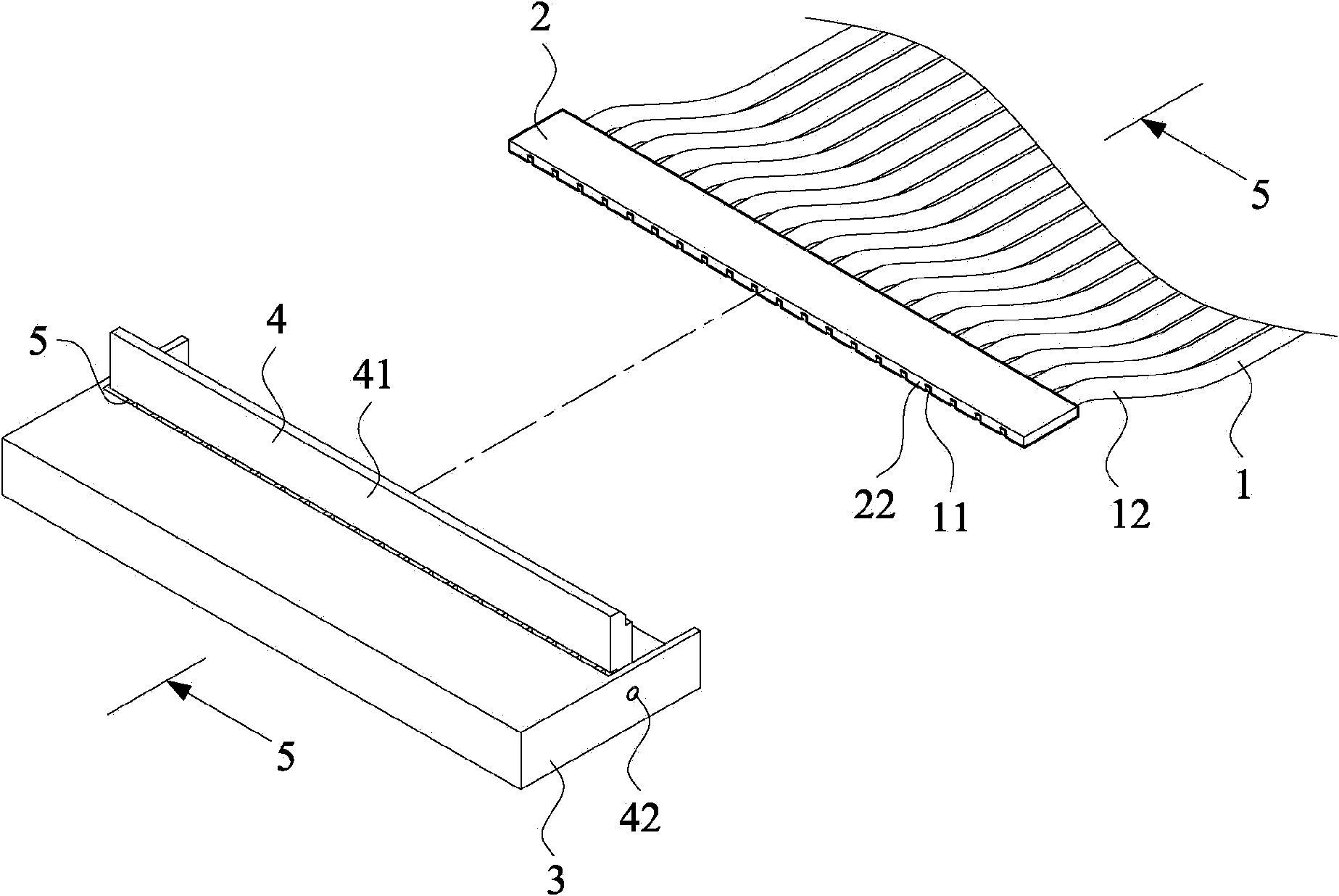

[0046] see also figure 1 and figure 2 as shown, figure 1 shows an exploded perspective view of the first embodiment of the present invention, figure 2 A perspective view of a first embodiment of the invention is shown. The wire plug-in structure of the present invention includes a plurality of wires 1 extending parallel to each other, wherein the wires 1 can be arranged in close proximity to each other, or each wire 1 can be separated from each other, and each wire 1 has a wire 11 and an insulating layer 12 covering the wire 11. As shown in the figure, one end of the wire 1 is defined as a plug-in end 13 , and the wire 11 protruding from the plug-in end 13 is defined as a conductive contact section 14 .

[0047] In this embodiment, the plug-in end 13 of the wire 1 is combined with a plug-in auxiliary unit 2. The plug-in auxiliary unit 2 includes a plurality of positioning grooves 21, and each positioning groove 21 extends parallel to each other and is arranged on the plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com