Projection optic system

A technology of projection optical system and optical system, applied in optics, optical components, photography, etc., can solve the problems of environmental control of projection objective lens system (vibration reduction design and temperature control difficulties, etc.), achieve small environmental control design, reduce costs, and reduce volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

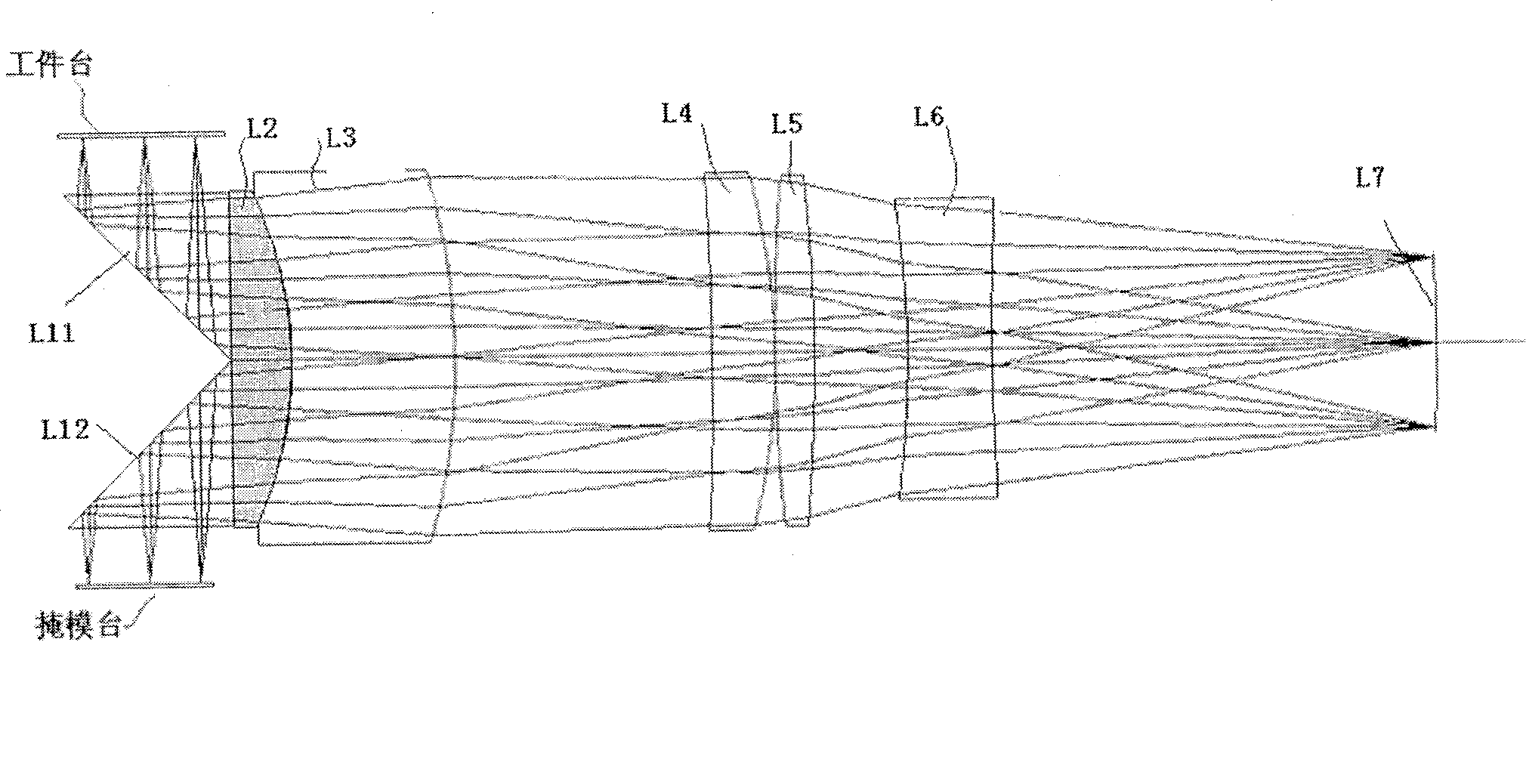

[0018] Below in conjunction with accompanying drawing and specific embodiment, the present invention is explained in more detail:

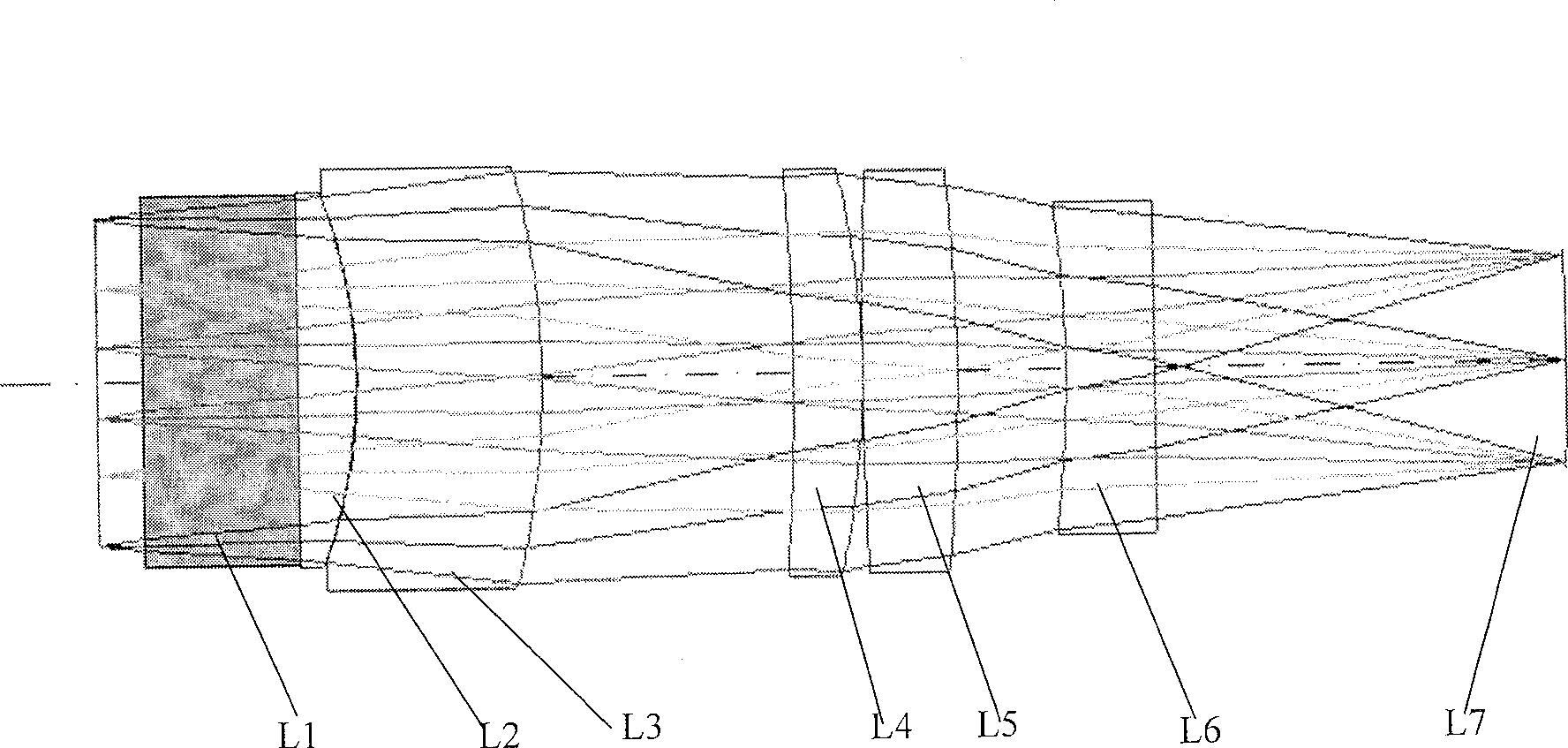

[0019] The present invention relates to a kind of optical system based on Wynne-Dyson structure, is characterized in that on the basis of traditional Wynne-Dyson optical system, inserts another telescopic lens group of positive and negative focal length, is used for reducing the length and the length of the whole optical system Increase the working distance of the optical system.

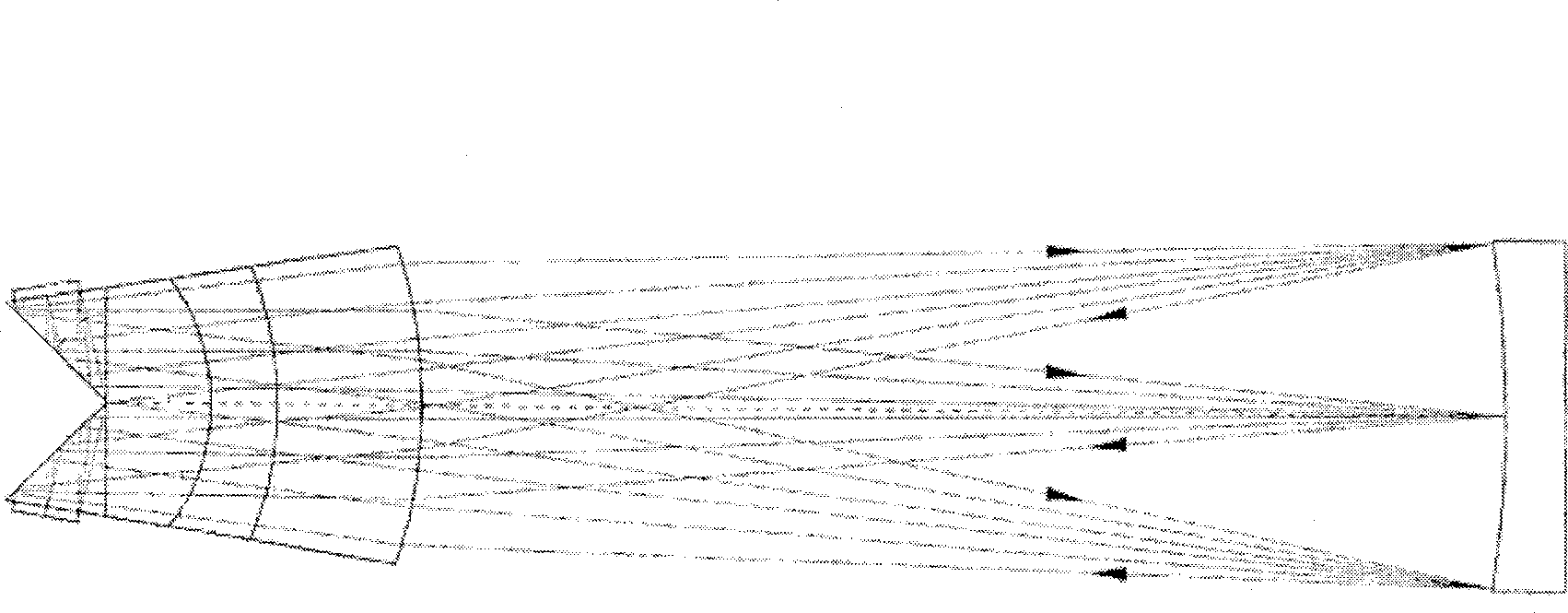

[0020] The present invention adopts a completely symmetrical optical design with a magnification of -1, and the axial aberration can be completely offset. It is mainly composed of a concave mirror and a mirror group with positive refractive power. The positive field curvature produced by the concave mirror can offset the front positive lens. The negative field curvature generated by the group; the mirror makes the imaging optical path pass through the optical elements o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap