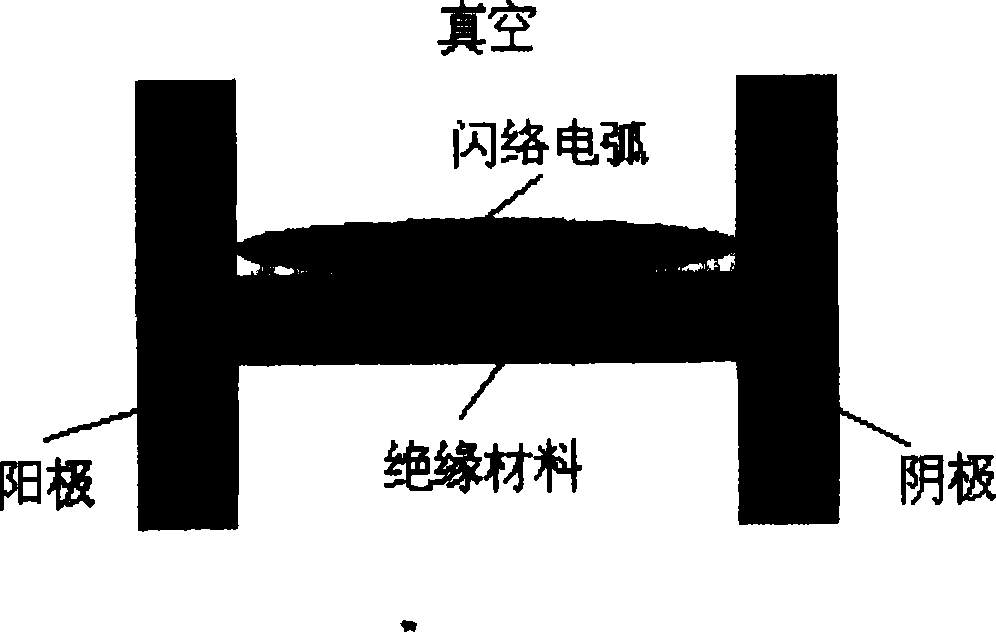

Vacuum insulation structure

A vacuum insulation and vacuum technology, applied in the direction of insulators, electrical components, circuits, etc., can solve the problems of poor radial insulation and poor longitudinal tensile strength, so as to increase the flashover voltage, increase the flashover field strength, and reduce the secondary The effect of the sub-electron emission coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

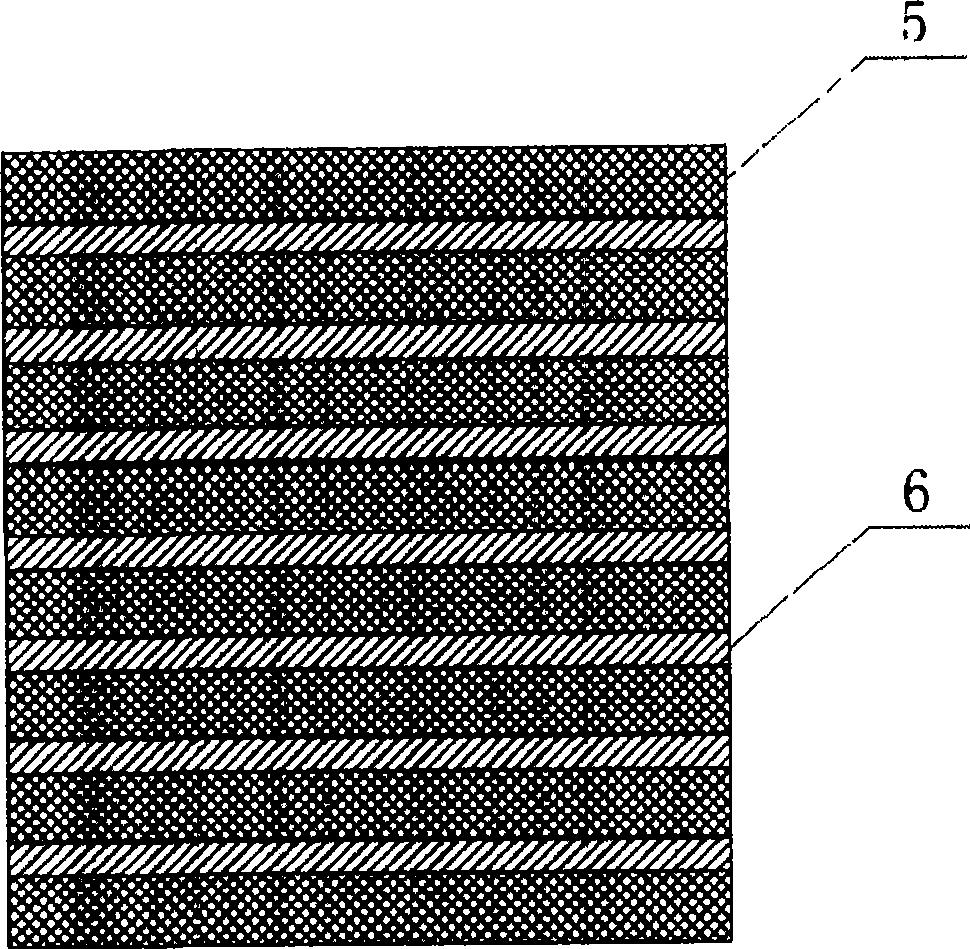

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

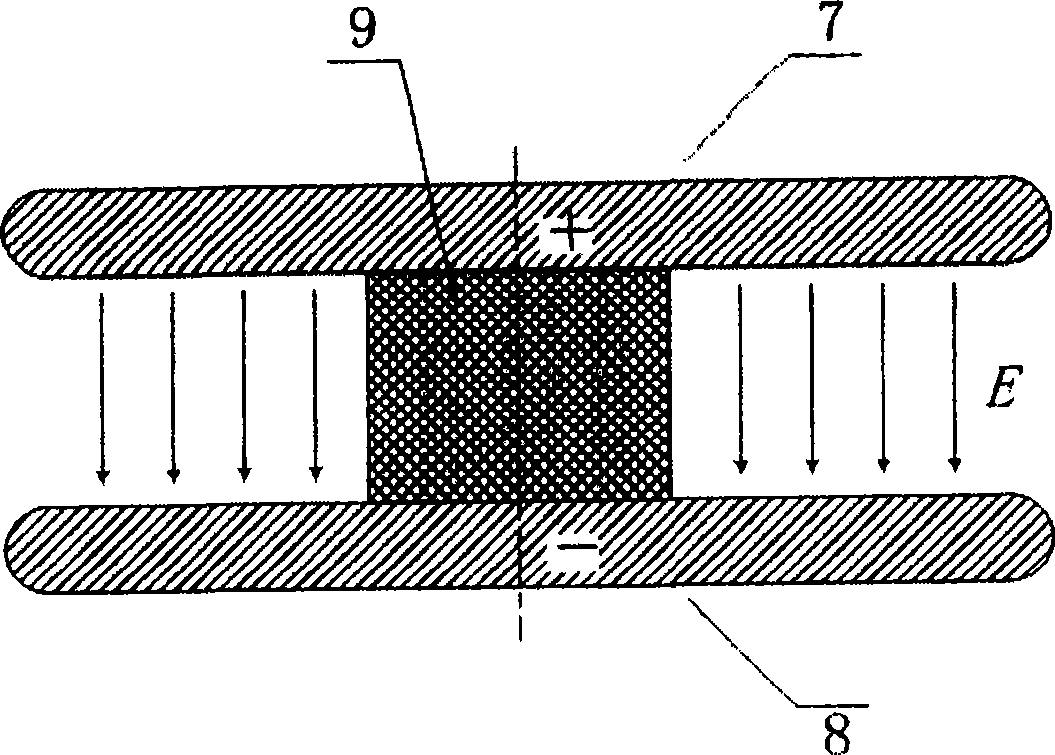

[0023] Such as Figure 5 As shown, the insulating matrix material 1 is a round rod-shaped polyimide, polyamide, polycarbonate, nylon 6, nylon 1010 material, with a diameter of 60 mm to 500 mm and a height of 30 mm to 200 mm; the insulating material film layer 2 It is alumina ceramics, chromium oxide ceramics or diamond-like carbon, and the thickness H1 of the insulating film is 1 micron to 100 microns, evenly distributed on the side of the cylinder of the base material; the main metal film layer 3 is a gold film layer or a titanium film layer or a zinc film The transition metal film layer 4 is located between the main metal film layer 3 and the insulating film layer 2, and is a 0.1 micron-0.3 micron thick chromium film layer; the metal film layer thickness H2 is 0.5 micron-10 micron, and the width W2 is 5 micron- 50 microns, and the distance W...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com