Micro-discharge equivalent simulation method and system for dielectric material with microstructure surface

A dielectric material and equivalent simulation technology, applied in the field of effective simulation, can solve problems such as consuming calculation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

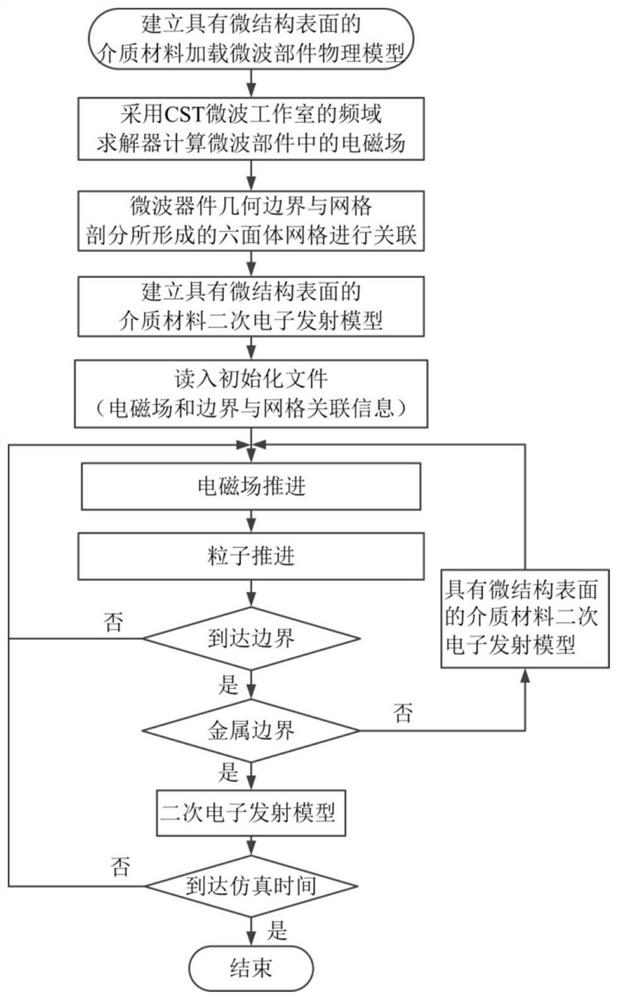

[0040] The specific implementation manner of the present invention will be further explained below in combination with specific examples and accompanying drawings.

[0041] The present invention is divided into following major steps:

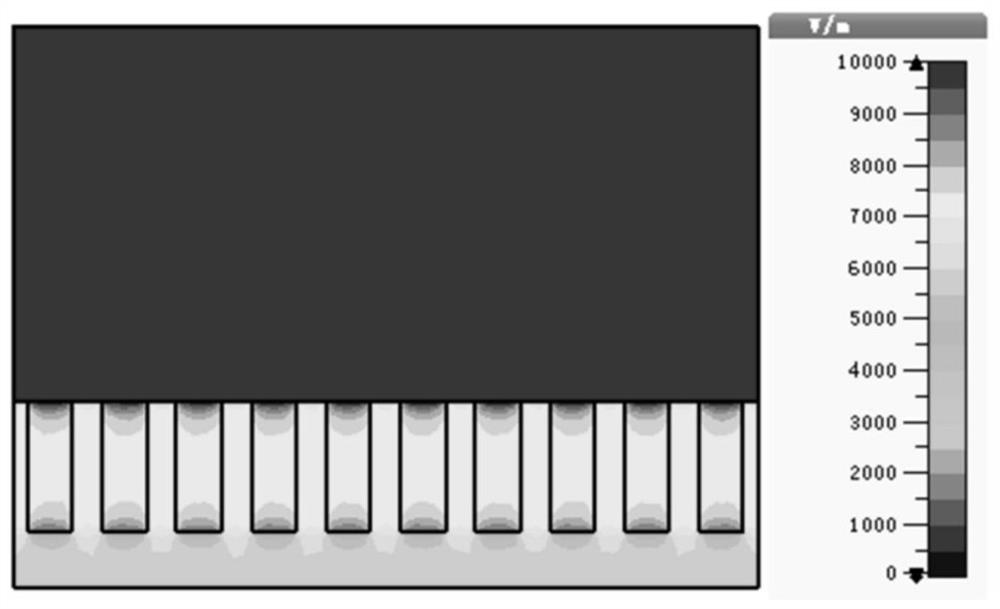

[0042]Step 1: Establish a physical model of a microwave component loaded with a dielectric material on a microstructured surface;

[0043] The second step: use the frequency domain solver model of CST Microwave Studio to simulate the electromagnetic field distribution inside the microwave component loaded by the dielectric material with the microstructure surface;

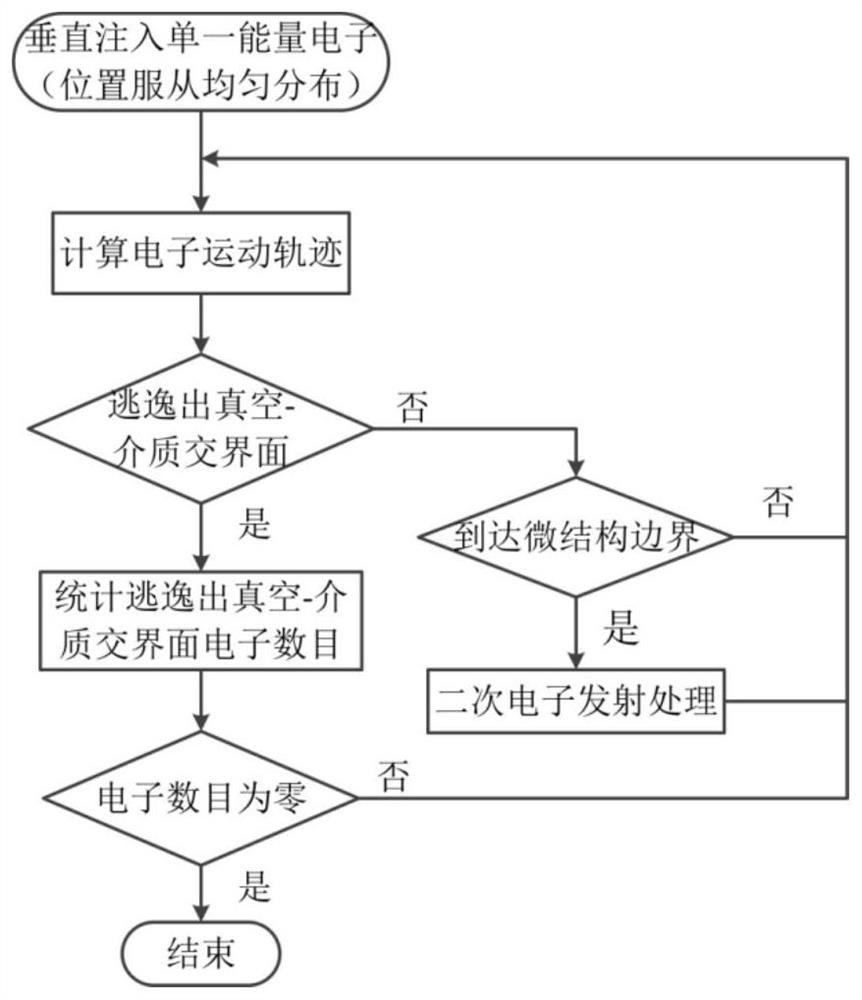

[0044] The third step: establish a secondary electron emission Monte Carlo model of the dielectric material with a microstructured surface;

[0045] Step 4: Establish a rapid equivalent simulation method for micro-discharge of dielectric-loaded microwave components with micro-structured surfaces;

[0046] In the third step, the secondary electron emission model of the dielectric ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com