Method for determining shape factor of particle swarm

A form factor, particle group technology, used in the analysis of materials, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

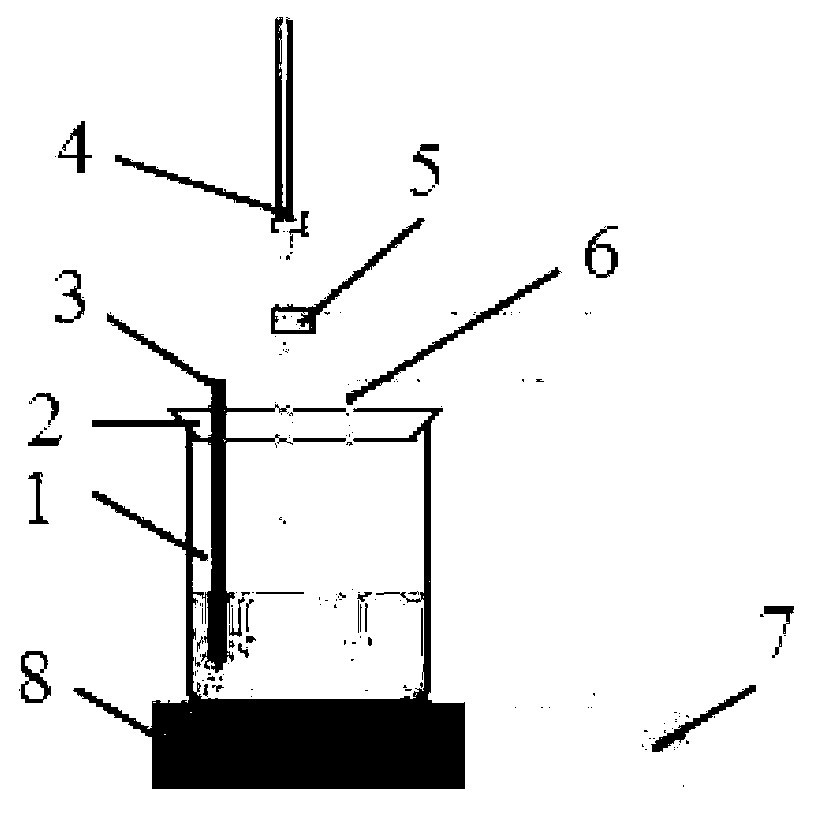

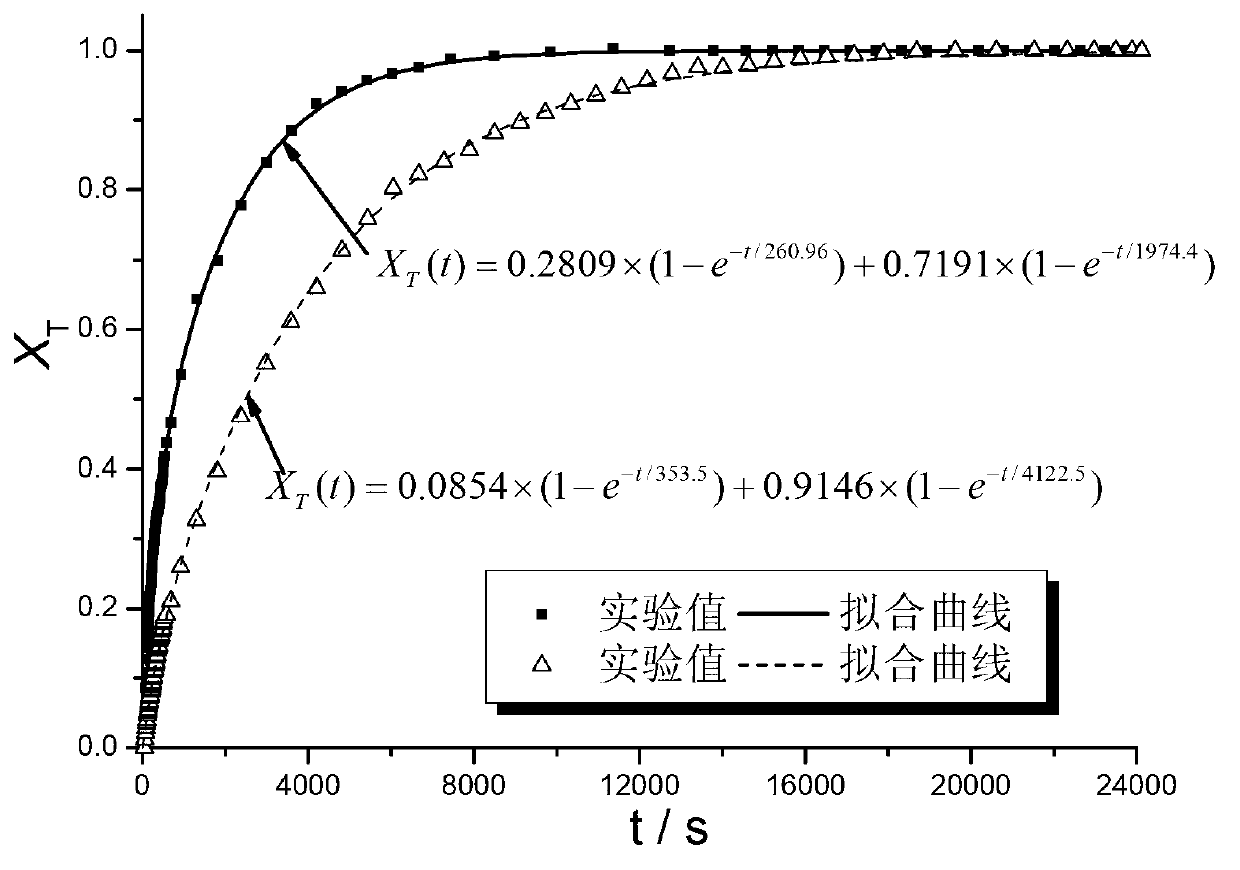

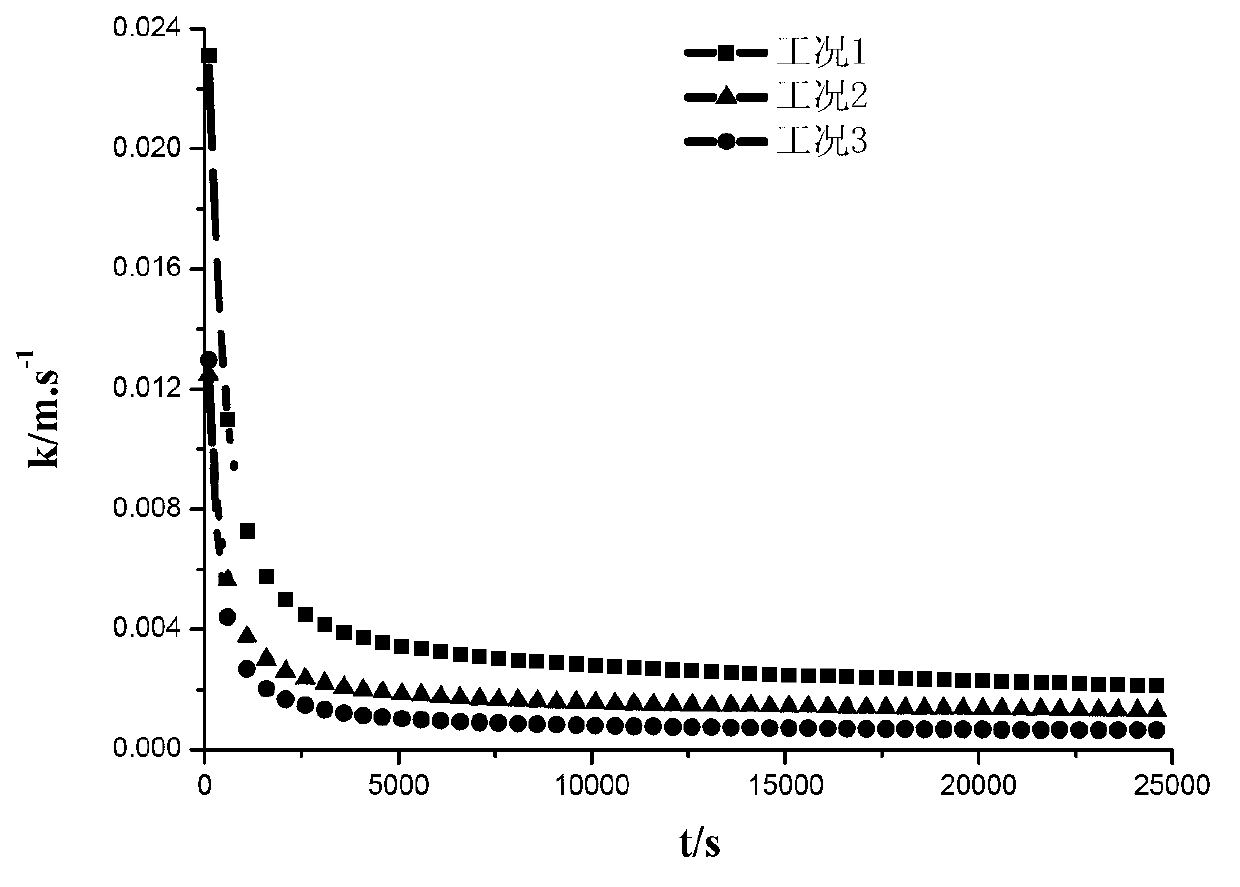

[0028] According to the measuring method of the present invention, the shape factor of the limestone particle group is measured. exist figure 1 In the experimental system shown, the dissolving reaction of limestone particles with hydrochloric acid was carried out under the conditions of constant temperature and constant solution concentration, and the reaction rule of solid dissolving and time was obtained. exist figure 1 In the system shown, the reaction bottle 1 is placed on a constant temperature magnetic heating stirrer 8, and the reaction bottle 1 is closed with a rubber stopper 2, and a thermometer 3, a pH value probe 6 and an acid burette 4 are inserted in it, and the other end of the pH value probe 6 is It is connected with the automatic potentiometric titrator 7, and the solenoid valve 5 connected with the automatic potenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com