Oil duct communication device

A communication device and oil circuit technology, applied in the connection with fluid cut-off device, through components, pipes/pipe joints/pipe fittings, etc., can solve the cumbersome installation and docking, damage to the submersible motor, and affect the normal operation of the submersible motor and other problems, to achieve the effect of easy oil circuit connection and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

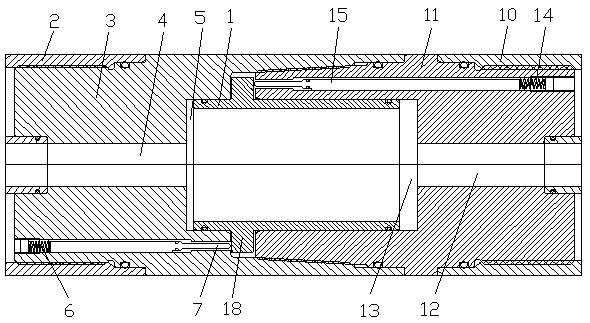

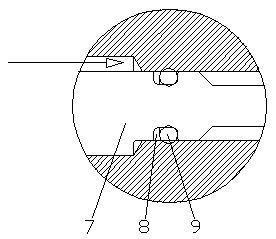

[0046] see Figure 1-Figure 3 , an oil circuit communication device, including a first joint piece, a joint pipe 1 and a second joint piece, the first joint piece includes a first shell 2, a first joint 3 and a first center pipe 4, the first shell The body 2 is connected to the first joint 3, and the first joint 3 is connected to the first central pipe 4 through a sealing ring. The first joint 3 is provided with a first medium channel and a first central hole 5 communicating with the first medium channel. , the first valve core thimble 7 is fixed through the first elastic element 6 in the first medium channel, the first valve core thimble 7 is provided with a first annular groove 8, and the first O ring is sleeved on the first annular groove 8 9;

[0047] The second joint part includes a second housing 10, a second joint 11 and a second central pipe 12, the second housing 10 is connected to the second joint 11, and the second joint 11 is connected to the second central pipe 1...

Embodiment 2

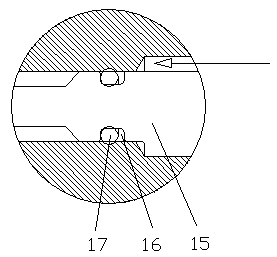

[0052] see figure 1 , Figure 4 and Figure 5 , an oil circuit communication device, including a first joint piece, a joint pipe 1 and a second joint piece, the first joint piece includes a first shell 2, a first joint 3 and a first center pipe 4, the first shell The body 2 is connected to the first joint 3, and the first joint 3 is connected to the first central pipe 4 through a sealing ring. The first joint 3 is provided with a first medium channel and a first central hole 5 communicating with the first medium channel. , the first valve core thimble 7 is fixed through the first elastic element 6 in the first medium channel, the first valve core thimble 7 is provided with a first annular groove 8, and the first O ring is sleeved on the first annular groove 8 9;

[0053] The second joint part includes a second housing 10, a second joint 11 and a second central pipe 12, the second housing 10 is connected to the second joint 11, and the second joint 11 is connected to the sec...

Embodiment 3

[0061] see Figure 4-Figure 6, an oil circuit communication device, including a first joint piece, a joint pipe 1 and a second joint piece, the first joint piece includes a first shell 2, a first joint 3 and a first center pipe 4, the first shell The body 2 is connected to the first joint 3, and the first joint 3 is connected to the first central pipe 4 through a sealing ring. The first joint 3 is provided with a first medium channel and a first central hole 5 communicating with the first medium channel. , the first valve core thimble 7 is fixed through the first elastic element 6 in the first medium channel, the first valve core thimble 7 is provided with a first annular groove 8, and the first O ring is sleeved on the first annular groove 8 9;

[0062] The second joint part includes a second housing 10, a second joint 11 and a second central pipe 12, the second housing 10 is connected to the second joint 11, and the second joint 11 is connected to the second central pipe 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com