Method for Improving AC Flashover Voltage of Polyimide Film

A technology of polyimide film and flashover voltage, which is applied in the direction of circuits, electrical components, insulators, etc., can solve the problem that the insulation performance of polyimide cannot meet the requirements, so as to reduce the secondary electron emission coefficient and realize Simple, low tool cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the objectives, technical solutions and advantages of the present invention clearer, the specific embodiments of the present invention will be further described in detail below.

[0016] The method for increasing the AC flashover voltage of a polyimide film includes the following steps:

[0017] 1) Cut the polyimide film into 7cm×2cm strips, wash with deionized water and n-propanol alternately for 5-10 times, then use an ultrasonic cleaner for cleaning, then rinse with deionized water, and place them in parallel. It was dried in a vacuum drying oven, and the drying time was 12 hours at a temperature of 40° C. in the vacuum drying oven.

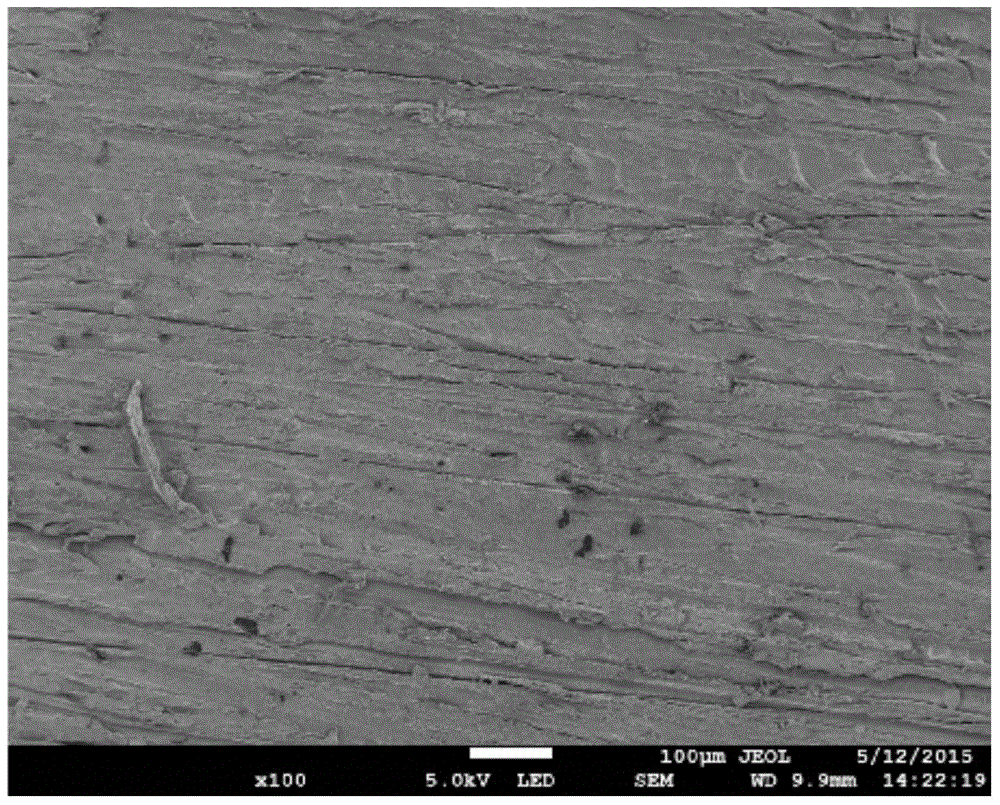

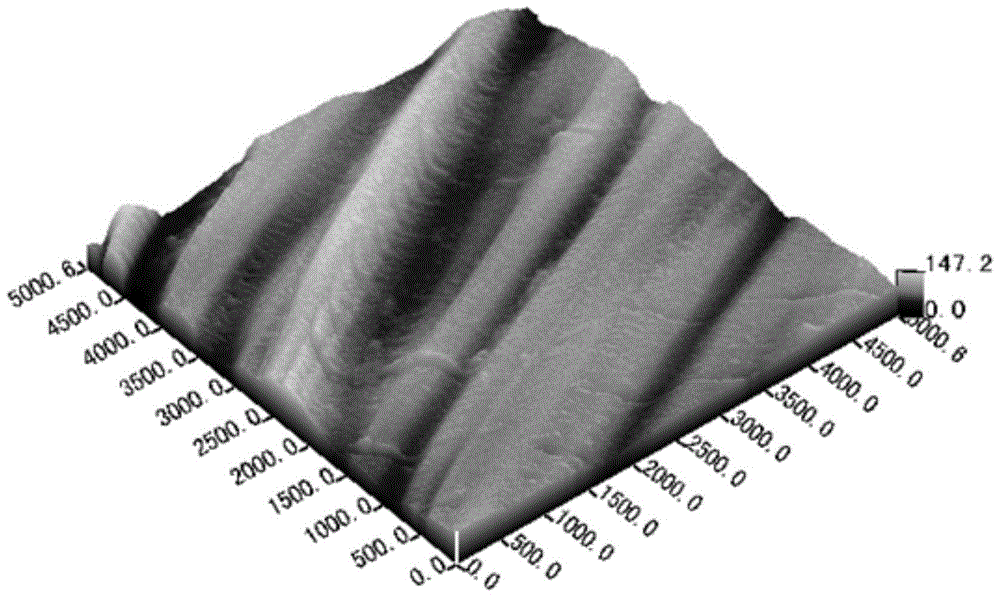

[0018] 2) Use 120-grit sandpaper to orient the polyimide film for 5-10 minutes. The grinding frequency is about 10-15 times per minute. The sanding direction should be perpendicular to the direction of the flashover field strength.

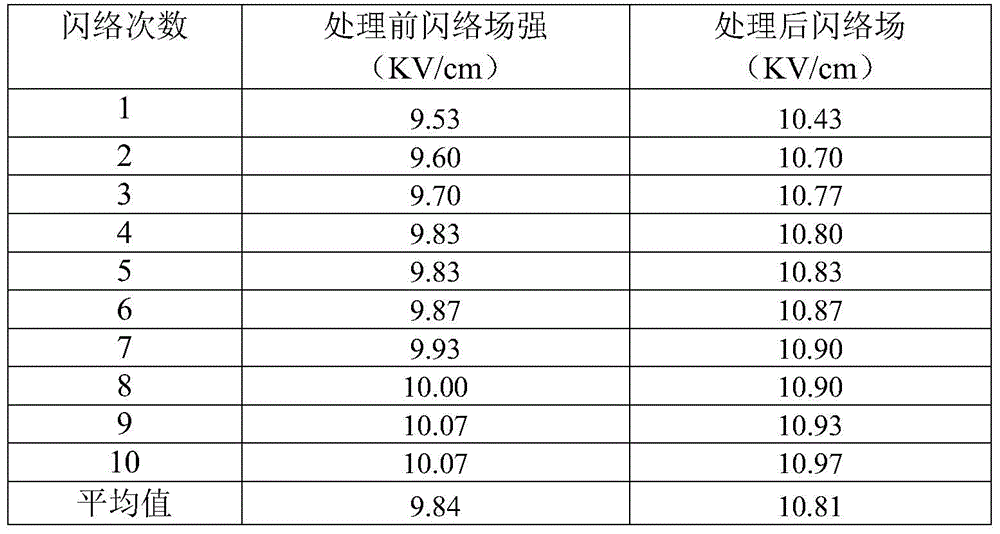

[0019] 3) The polished polyimide is cleaned and dried in a vacuum drying oven, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com