Secondary-electron emission angle distribution testing system

A technology of secondary electron emission and secondary electrons, which is applied in the direction of material analysis, measurement device, and material analysis using wave/particle radiation, which can solve the problem that the processing technology of position-sensitive detectors is difficult to realize, and the physical structure and electronic system are complicated. , the influence of test data accuracy, etc., to achieve the effect of improving test efficiency, low secondary electron emission coefficient, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

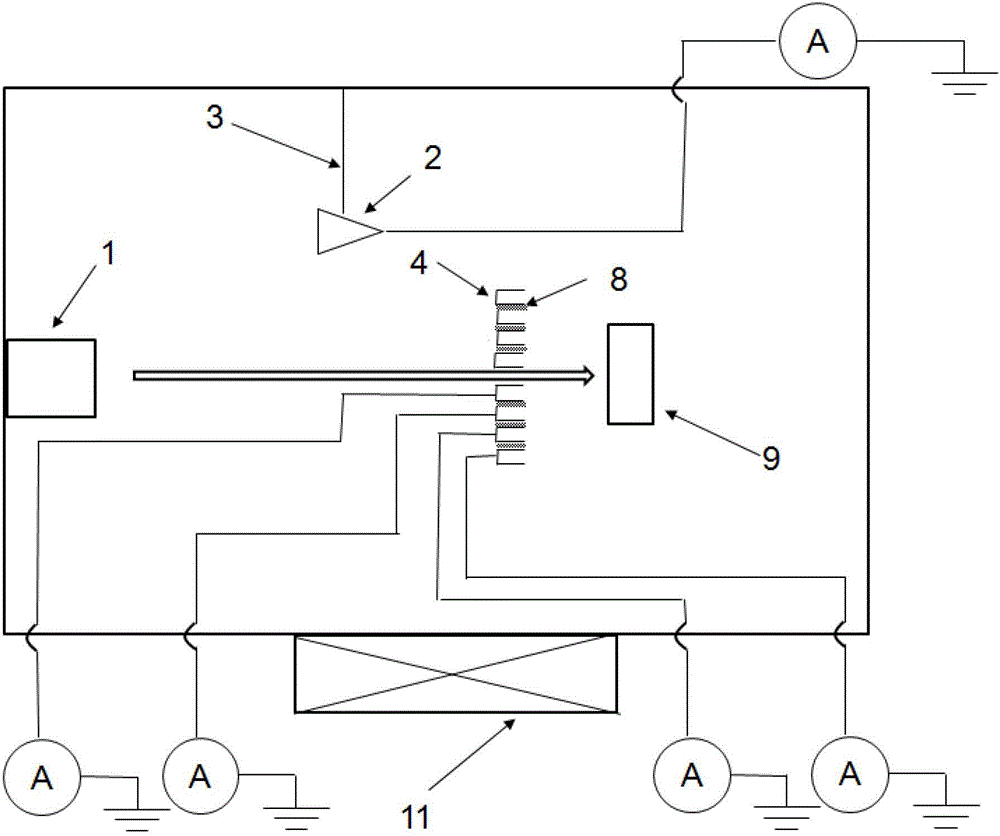

[0028] See attached figure 1 , a secondary electron emission angular distribution testing system, which includes: electron gun 1, Faraday cup 2, lifting device 3, secondary electron collection ring, insulating ring 8, sample holder 9, electrometer and vacuum system 11;

[0029] The electron gun 1, Faraday cup 2, lifting device 3, secondary electron collection ring, insulating ring 8 and sample holder 9 are installed inside the vacuum system 11; the electrometer is installed outside the vacuum system 11;

[0030] The electron gun 1 is used to generate an incident electron beam;

[0031] The Faraday cage 2 is installed on the lifting device 3;

[0032] The sample holder 9 is used to place the test sample, so that the incident electron beam generated by the electron gun 1 is horizontally directed to the test sample;

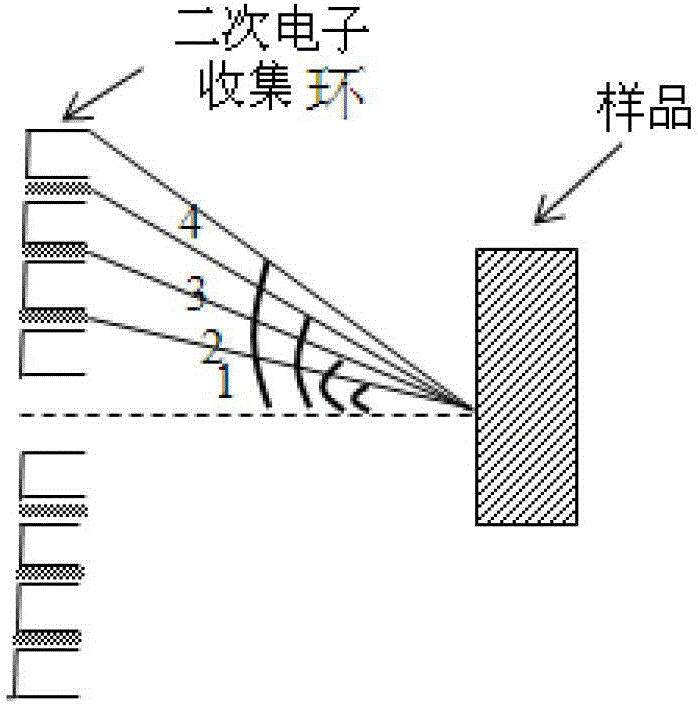

[0033] The quantity of the secondary electron collection ring is 4, and the shape of the secondary electron collection ring is a ring, which is placed between the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com