Sewage treatment equipment

A technology of sewage treatment device and water inlet pipe, which is applied in adsorption water/sewage treatment, filtration and separation, gravity filter, etc., can solve the problems of large power consumption, large area and high operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

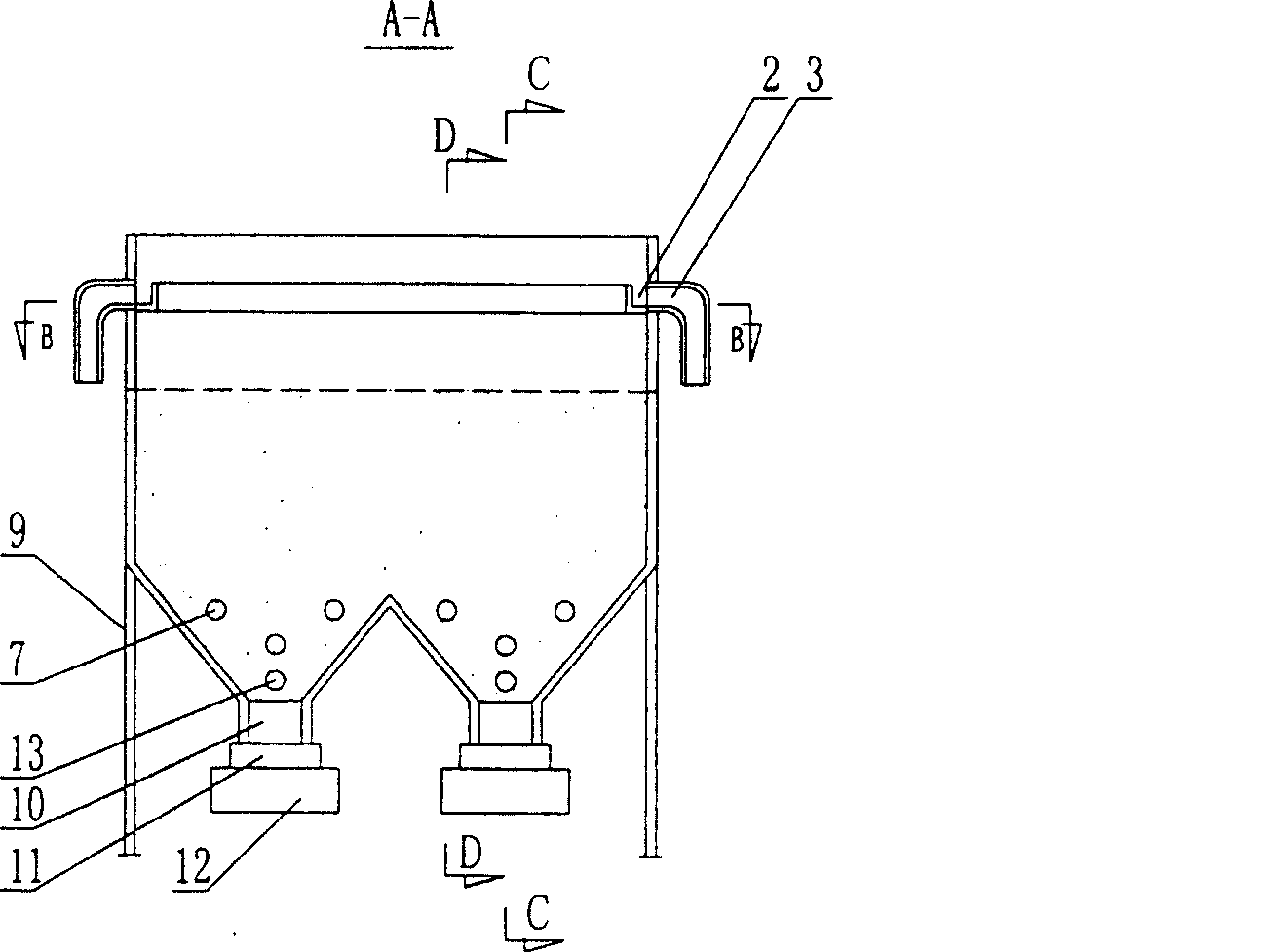

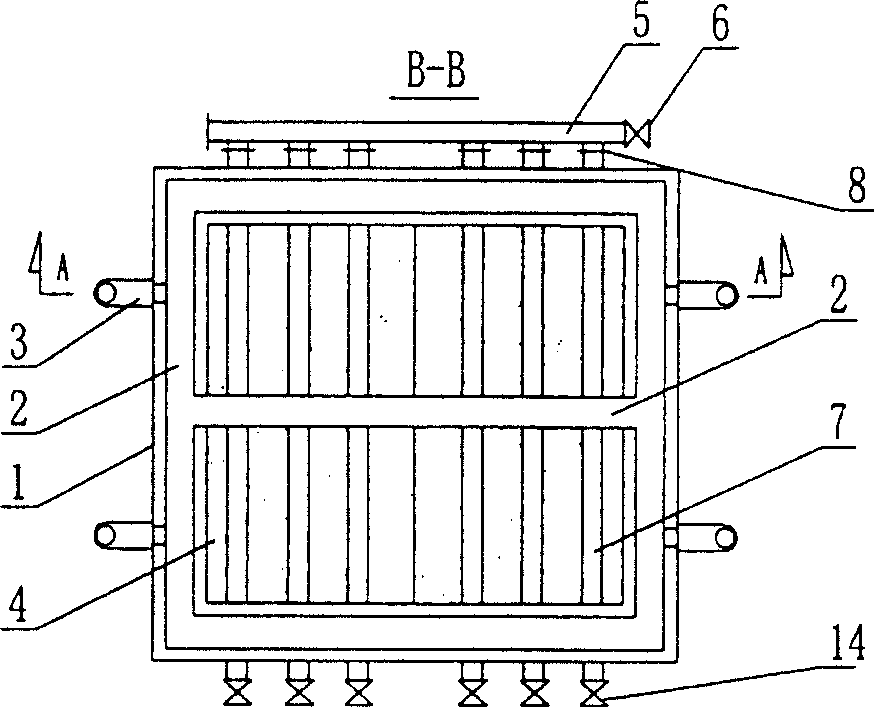

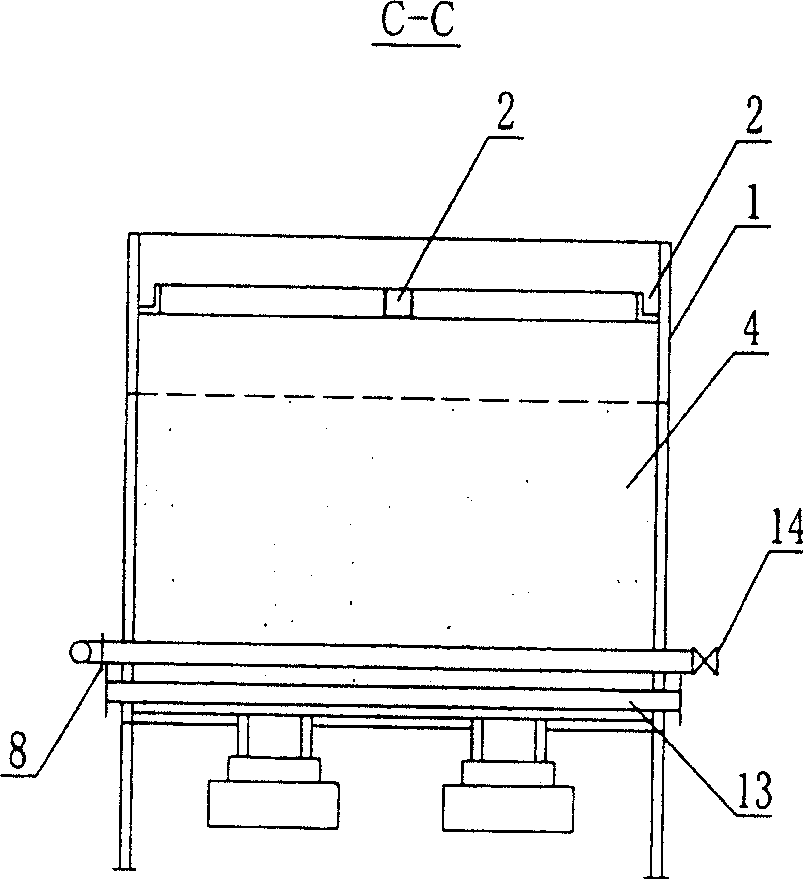

example 1

[0048] A paper mill adopts two activated coke adsorption beds in parallel to recycle the biochemically treated wastewater after deep treatment. The composition of wastewater after biochemical treatment is:

[0049] Chemical oxygen demand (COD) 370mg / L, biochemical oxygen demand (BOD) 110mg / L, suspended solids (SS) 255mg / L,

[0050] The chromaticity is 96 times, the chloride root is 1130mg / L, the alkalinity is 12.4mg / L, the hardness is 7mg / L, the conductivity is 5050, and the pH value is 11.07.

[0051] Activated coke adsorption bed parameters:

[0052] 1. Width: 4,000mm

[0053] 2. Height: 4,000mm

[0054] 3. Length: 10,000mm

[0055] 4. Treated water volume: 40m 3 / Hour

[0056] 5. Water inlet pipe: DN30

[0057] 6. Inlet branch pipe: DN30

[0058] 7. Water inlet supervisor: DN150

[0059] 8. Diameter of water inlet orifice: 8mm

[0060] 9. Outlet branch pipe: DN100

[0061] The body of the active coke adsorption bed provided by the present invention is a cuboid, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com