Electrothermal oil roller system

An oil roller and electric heating technology, which is applied in the direction of rolling, lamination, metal rolling, etc., can solve the problems of low safety factor, broken safety valve, inconvenient operation, etc., increase the service life, prolong the service life, and solve the problem of heat generation serious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

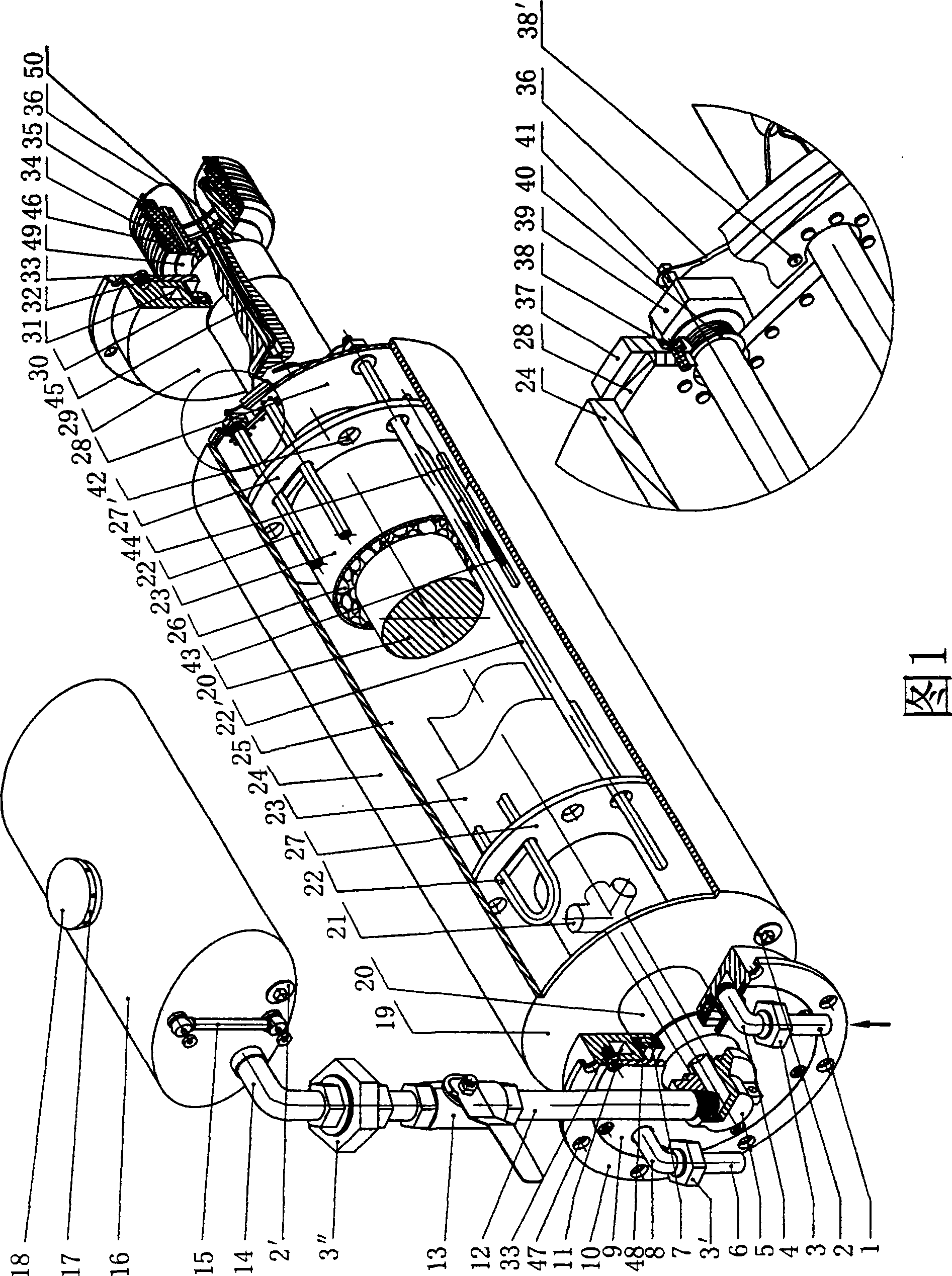

[0035] Please refer to Figure 1. Figure 1 is a schematic structural diagram of an electric heating oil roller system of the present invention. The oil roller assembly, the oil roller supporting and rotating assembly, the oil roller heating assembly, and the oil roller energy storage assembly constitute a complete electric heating oil roller system. The specific structure of each assembly is as follows:

[0036] In the oil roller assembly:

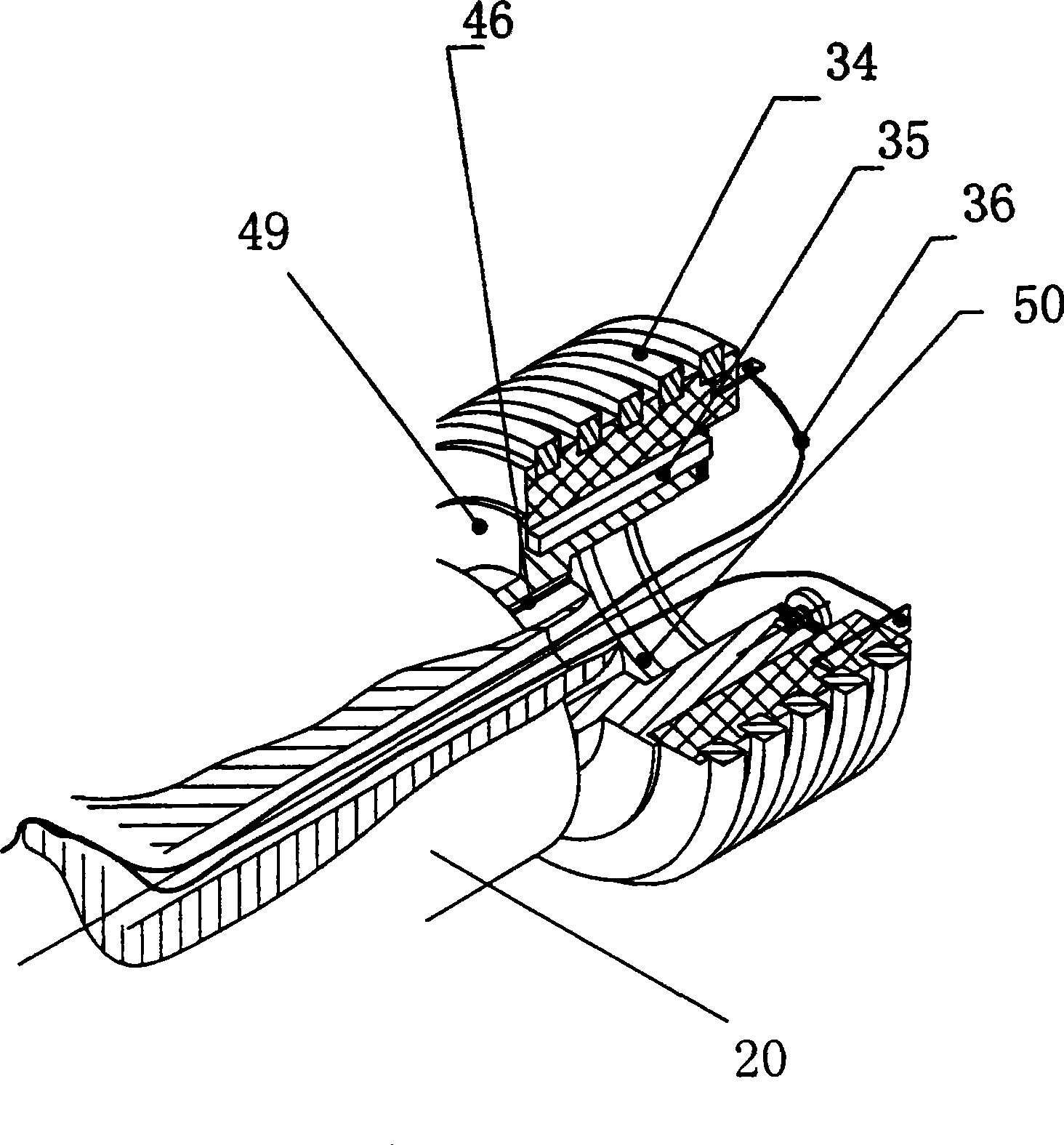

[0037] The hot roller mandrel 20 is in the form of a through shaft or a half shaft. One end is provided with a mandrel oil hole 21 leading from the shaft end and provided with internal threads, a rotary joint is installed as the guide 5, and the other end is provided with a threading hole 45 and a keyway 46 The slip ring 34 is installed, and the shaft end is fixed with a gland 50.

[0038] Two bearing positions are provided on the shoulders on both sides of the heat roller core shaft 20, and the left cooling bearing seat 10 and the right coolin...

Embodiment 2

[0081] The structure of an electric heating oil roller system in Embodiment 2 is basically the same as that in Embodiment 1, except for the structure of the cooling bearing seat.

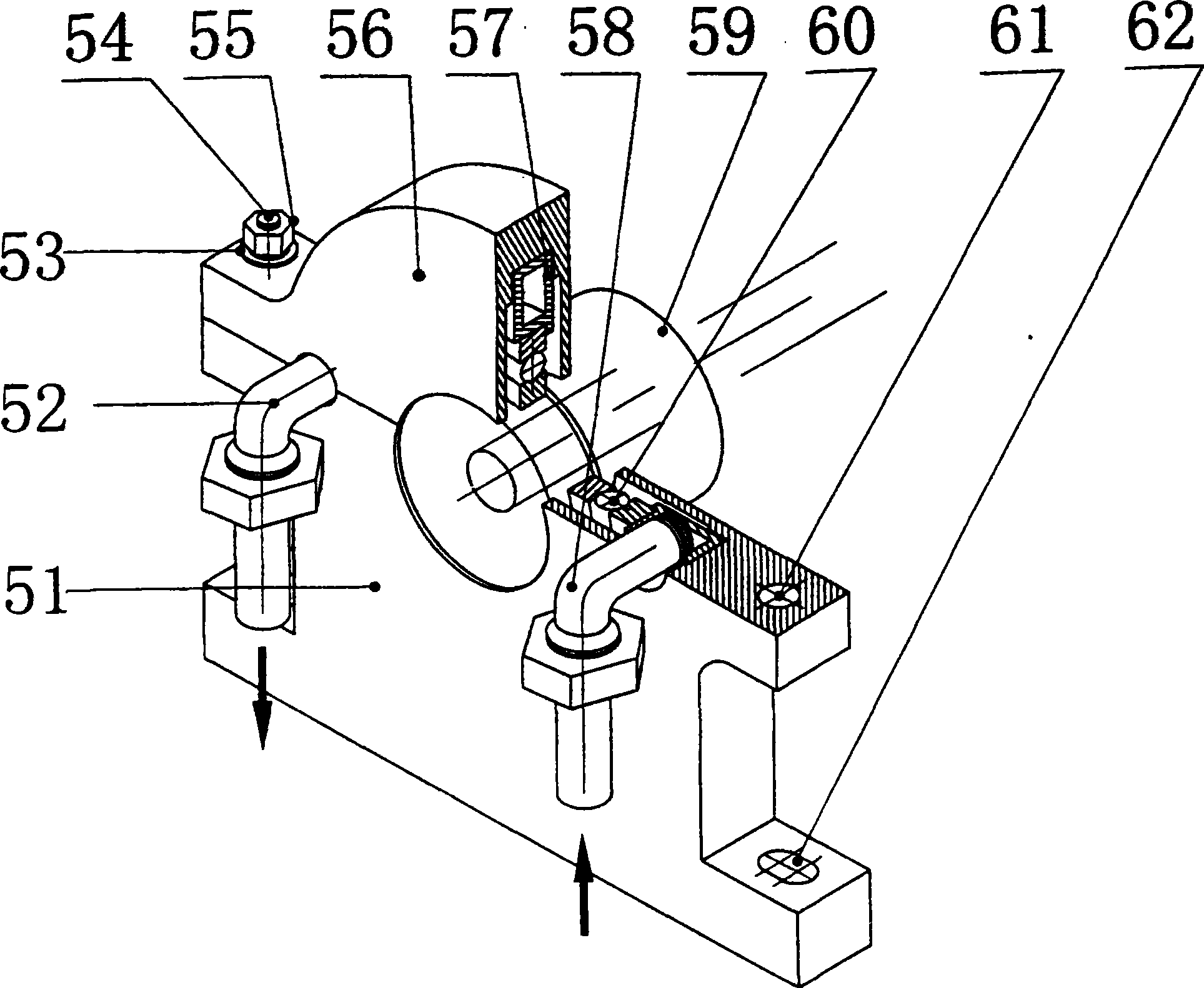

[0082] The cooling bearing seat is an open-close type, and its main structure includes an upper bearing seat, a lower bearing seat, a cooling water jacket, a water inlet pipe and a water outlet pipe.

[0083] The upper bearing seat and the lower bearing seat are correspondingly provided with a semicircular groove. When the upper and lower bearing seats are fixed together, a circular groove is formed, and the cooling water is embedded in the groove The cooling water jacket is made of an annular tube, and the bearing is sleeved in the inner diameter bearing chamber of the cooling water jacket. During installation, first fix the bearing in the bearing position of the hot roller mandrel, then put a cooling water jacket on the outside of the bearing, and then place the cooling water jacket in the semicircula...

Embodiment 3

[0091] The structure of the cooling bearing seat in Embodiment 3 is basically the same as that in Embodiment 2. The difference is that there is a semi-circular ring-shaped cooling water jacket 66 in the upper and lower bearing seats, but the cooling water jacket 66 is independent, and the semi-circular ring tube The two ends are closed and are independently arranged in the lower bearing seat 64 and the upper bearing seat 65.

[0092] The whole of the cooling bearing seat is open and closed, and its main structure includes an upper bearing seat, a lower bearing seat, a cooling water jacket, a water inlet pipe and a water outlet pipe.

[0093] The upper bearing seat and the lower bearing seat are respectively provided with a semicircular bearing chamber corresponding to each other, and a circular bearing chamber is formed when the upper and lower bearing seats are fixed together. When the upper and lower bearing housings are fixed together, the cooling water jacket 66 is still an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com