Air purifying installation

An air purification device and air purification technology, which are applied in air conditioning systems, space heating and ventilation, chemical instruments and methods, etc., can solve the problems of low efficiency and cumbersome maintenance of air purification devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

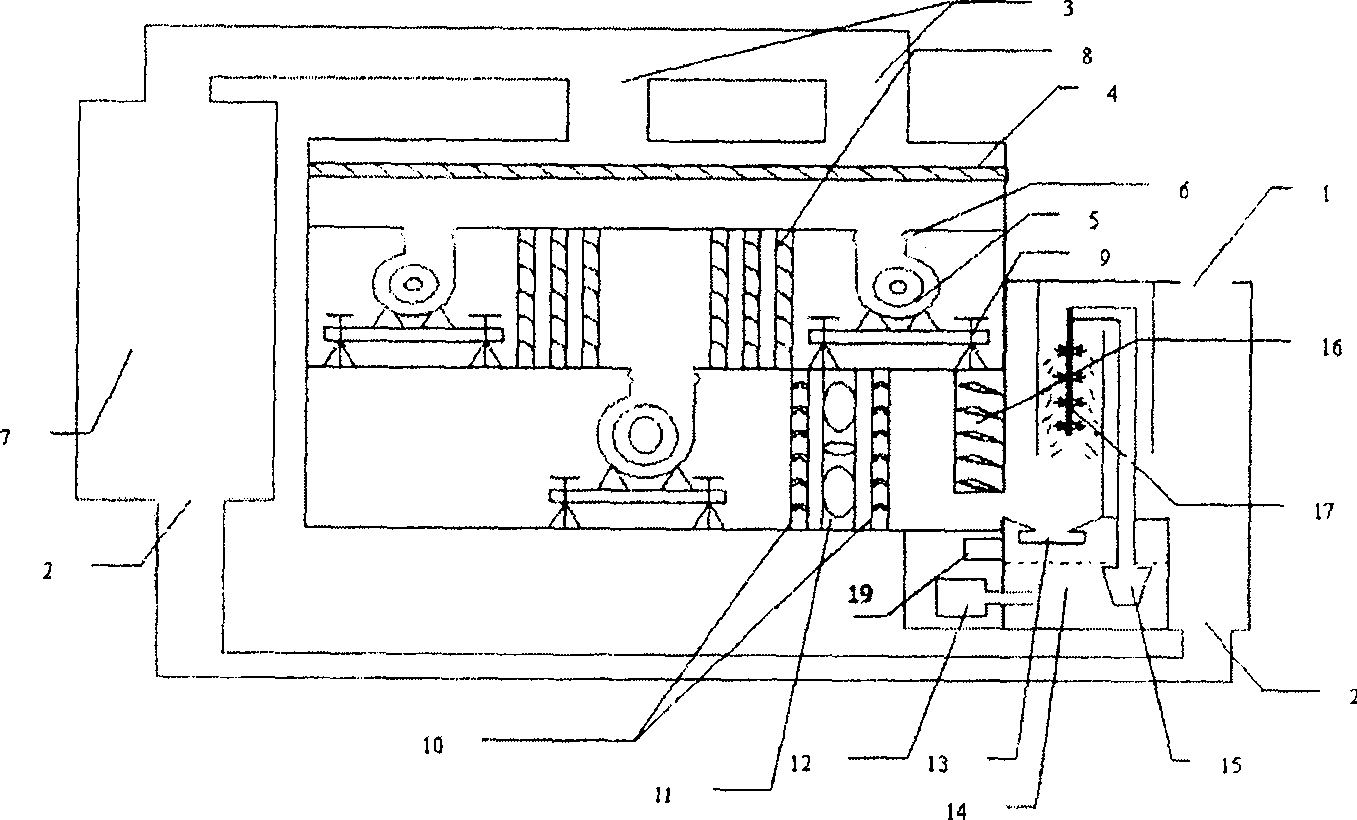

[0033] as attached figure 1 Shown, is one of the implementation of the present invention as aseptic room air purification and sterilization equipment. The air in the working room to be sterilized is driven by three fans 5, and enters the device from the return air outlet 2 or the fresh air outlet 1, and the dirty air first passes through the multi-layer cleaning liquid mist containing disinfectant sprayed by the multi-layer nozzle 17 area, most of the germs, dust and solid particles are washed into the dust container 13 by the water mist, and at the same time, the water mist of the cleaning liquid is filtered through the filter at the bottom of the dust container and returned to the cleaning liquid tank 14, and then pumped into the cleaning liquid tank by the water pump 15. The multi-layer shower head 17 is recycled. The air that has been preliminarily purified by water washing and filtration is regulated by the surface cooler 16, and sterilized and filtered through photocata...

Embodiment 2

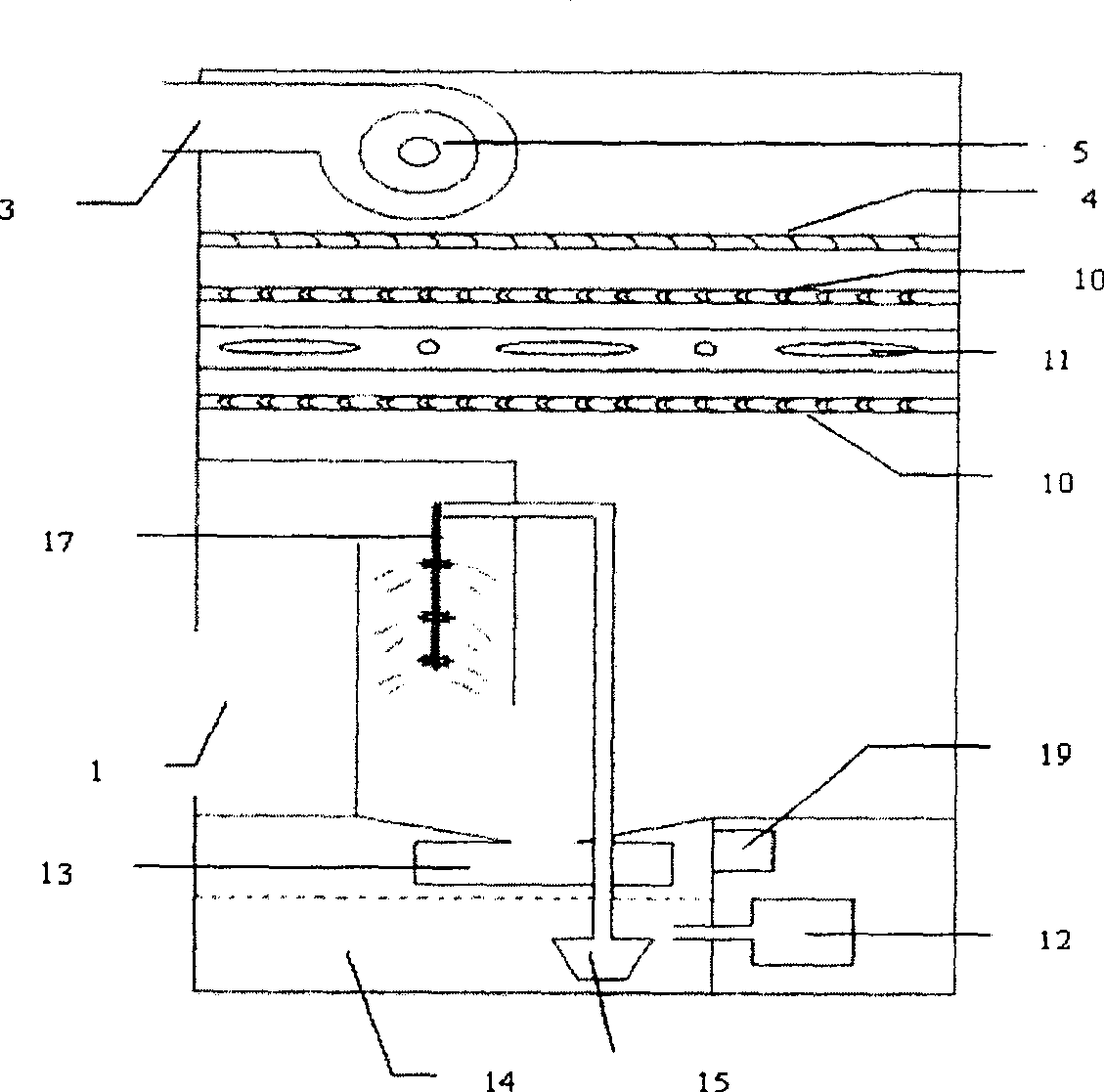

[0035] Such as figure 2 As shown, it is the purification and sterilization equipment for poultry and livestock farms. The air in the working room to be sterilized is driven by the fan 5 on the top floor and enters the equipment from the fresh air outlet 1 of the poultry house. The dirty air first passes through the multi-layer cleaning liquid water mist area sprayed by the multi-layer nozzle 17, which contains disinfectant. Most of the germs, dust and solid particles are washed and dropped into the dust container 13 by the water mist. At the same time, the water mist of the cleaning liquid is filtered through the filter at the bottom of the dust container and then returned to the cleaning liquid tank 14. Excited to make it rich in ozone and negative ions, and then pumped into the multi-layer nozzle 17 by the water pump 15 for recycling. The air that has been preliminarily purified by water washing and filtration is sterilized and filtered through the photocatalyst net, elect...

Embodiment 3

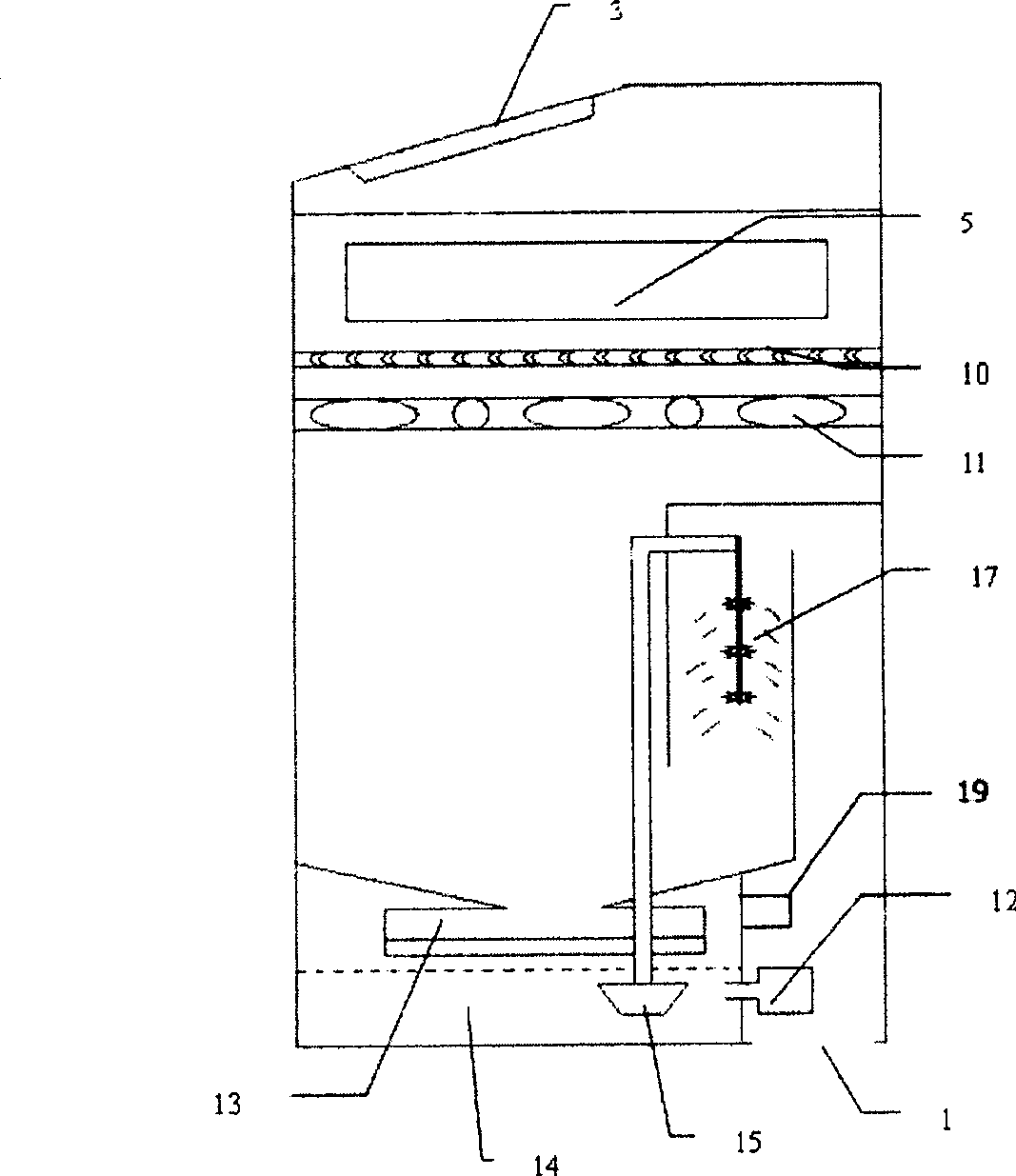

[0037] Such as image 3 As shown, it is an air purification and disinfection machine equipment. The air in the working room to be sterilized is driven by the fan 5 on the top floor and enters the equipment from the indoor fresh air outlet 1. The dirty air first passes through the multi-layer cleaning liquid water mist area sprayed by the multi-layer nozzle 17, most of which Germs, dust and solid particles are all washed down into the dust container 13 by the water mist, and at the same time, the water mist of the cleaning liquid is filtered through the filter at the bottom of the dust container and returned to the cleaning liquid tank 14, which is excited by the ozone generator and the negative ion generator. Make it rich in ozone and negative ions, and then be pumped into the multi-layer nozzle 17 by the water pump 15 for recycling. The air that has been preliminarily purified by water washing and filtering is sterilized and filtered through the photocatalyst net, electronic...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap