Straightening machine frame pretightening technology

A technology of straightening machine and frame, which is applied in the field of straightening process of tube and bar straightening machine, which can solve the problems of insurmountable straightening accuracy and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

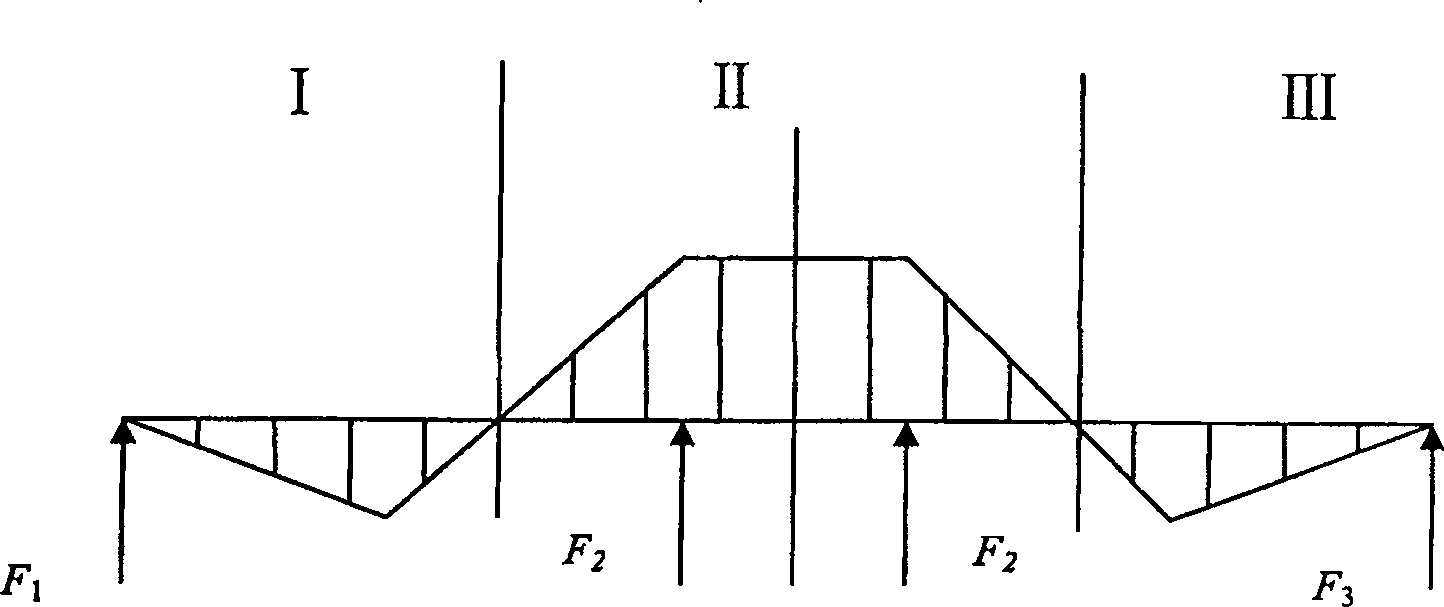

[0033] figure 1 , is the distribution map of the stress area of the roll. F in the picture 1 ——Front Roller Force——Zone I, F 2 ——The force of the middle roller——Zone II, F 3 ——Rear roller force——Zone III.

[0034] It can be seen from the figure that compared with the front and rear area rollers, the flattening force of the middle roller on the pipe is much greater, and the corresponding straightening force transmitted to the upper and lower beams is not uniform. Therefore, the present invention adjusts the pre-tightening force by distributing the pre-tightening force in proportion to improve the whole load system.

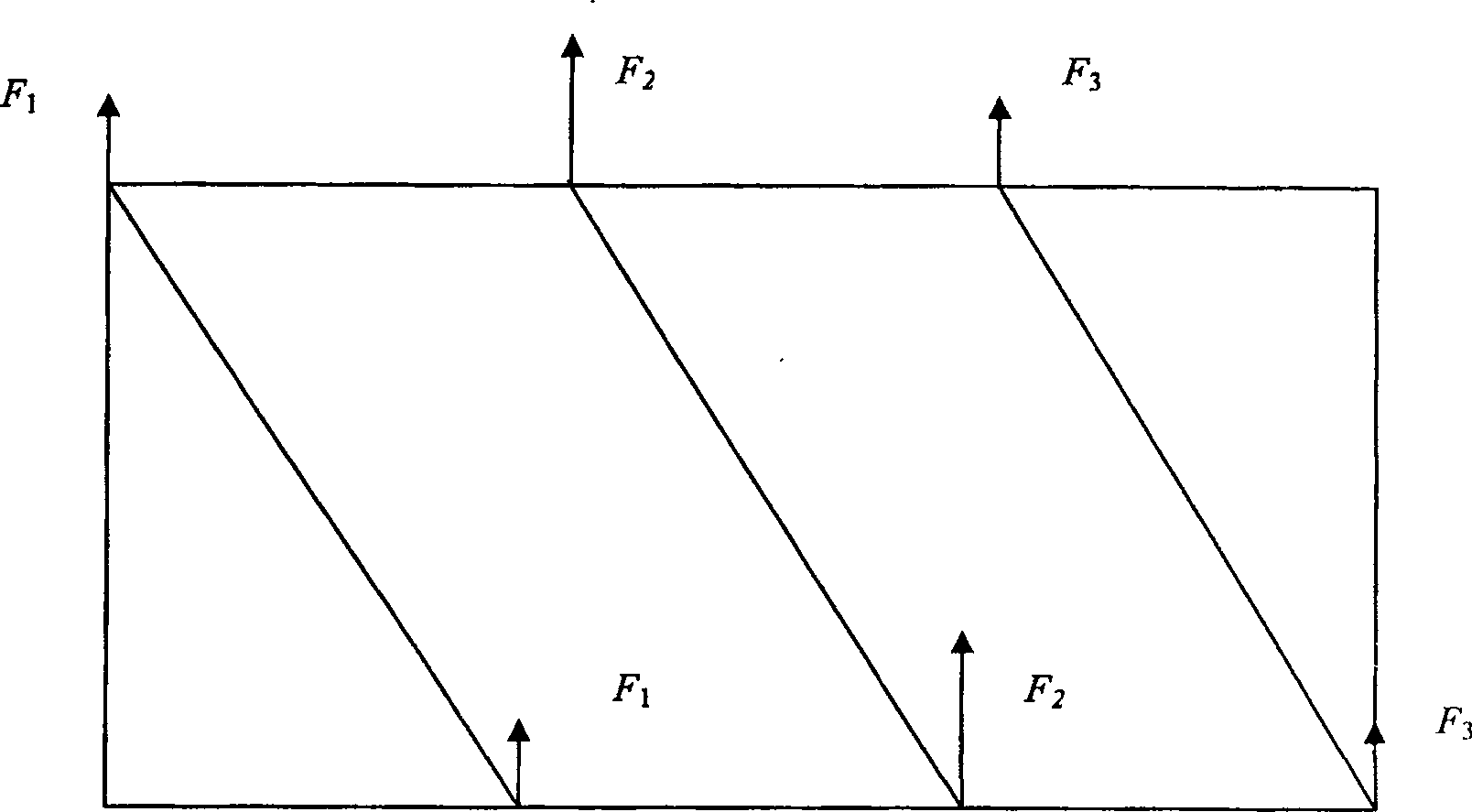

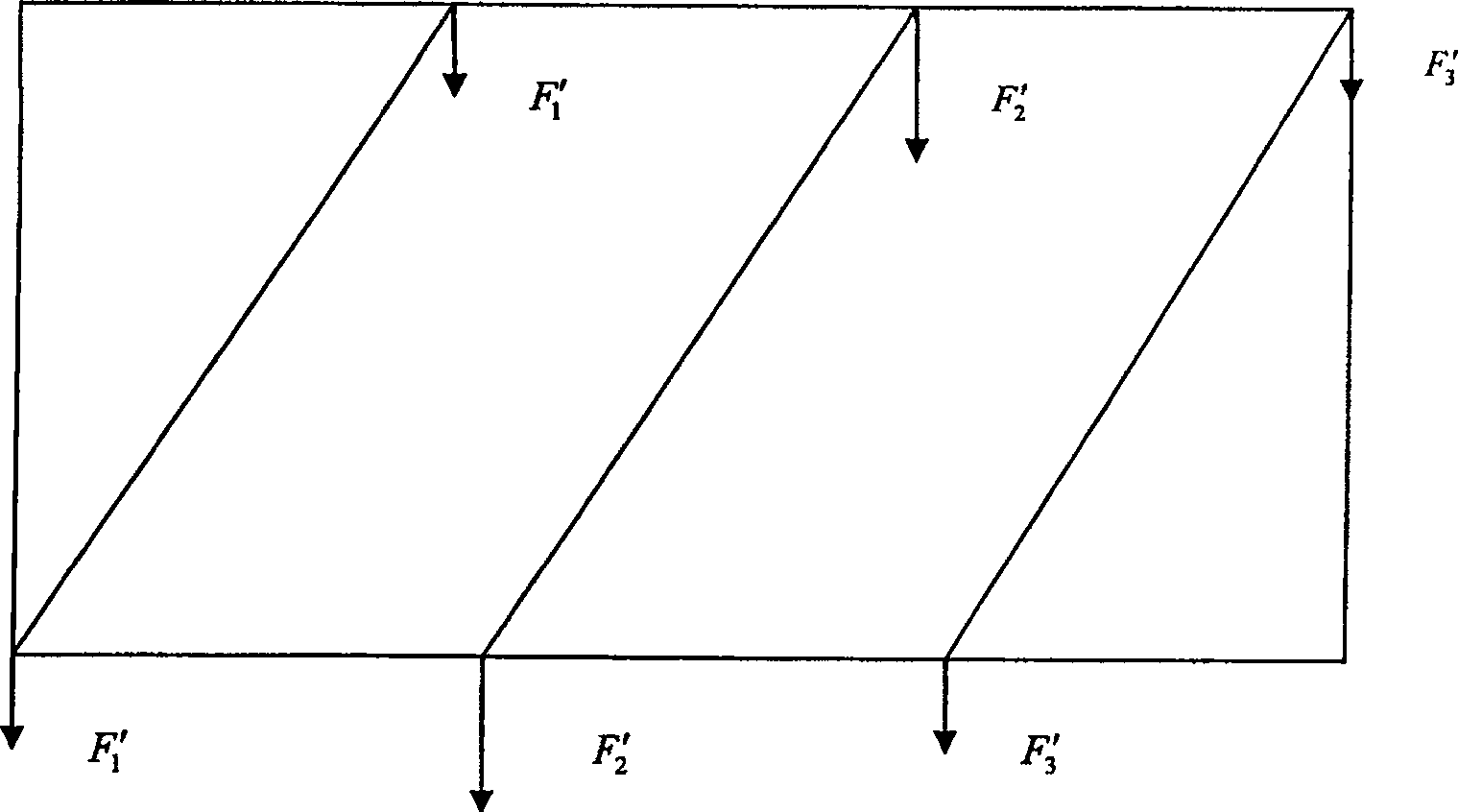

[0035] figure 2 , image 3 , Figure 4 middle, figure 2 is the force diagram of the upper beam in the working state, image 3 is the force diagram of the lower beam under working condition, Figure 4 It is the resultant force ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com