Macromolecular polymerization reaction trough

A technology of polymer polymerization and reaction tank, which is applied in the field of polymer polymerization reaction tank, which can solve the problem that the technology and market demand cannot be met, the amount of gel or insoluble matter is difficult to control, and it is not suitable for the production of polymer products with fine gel content, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

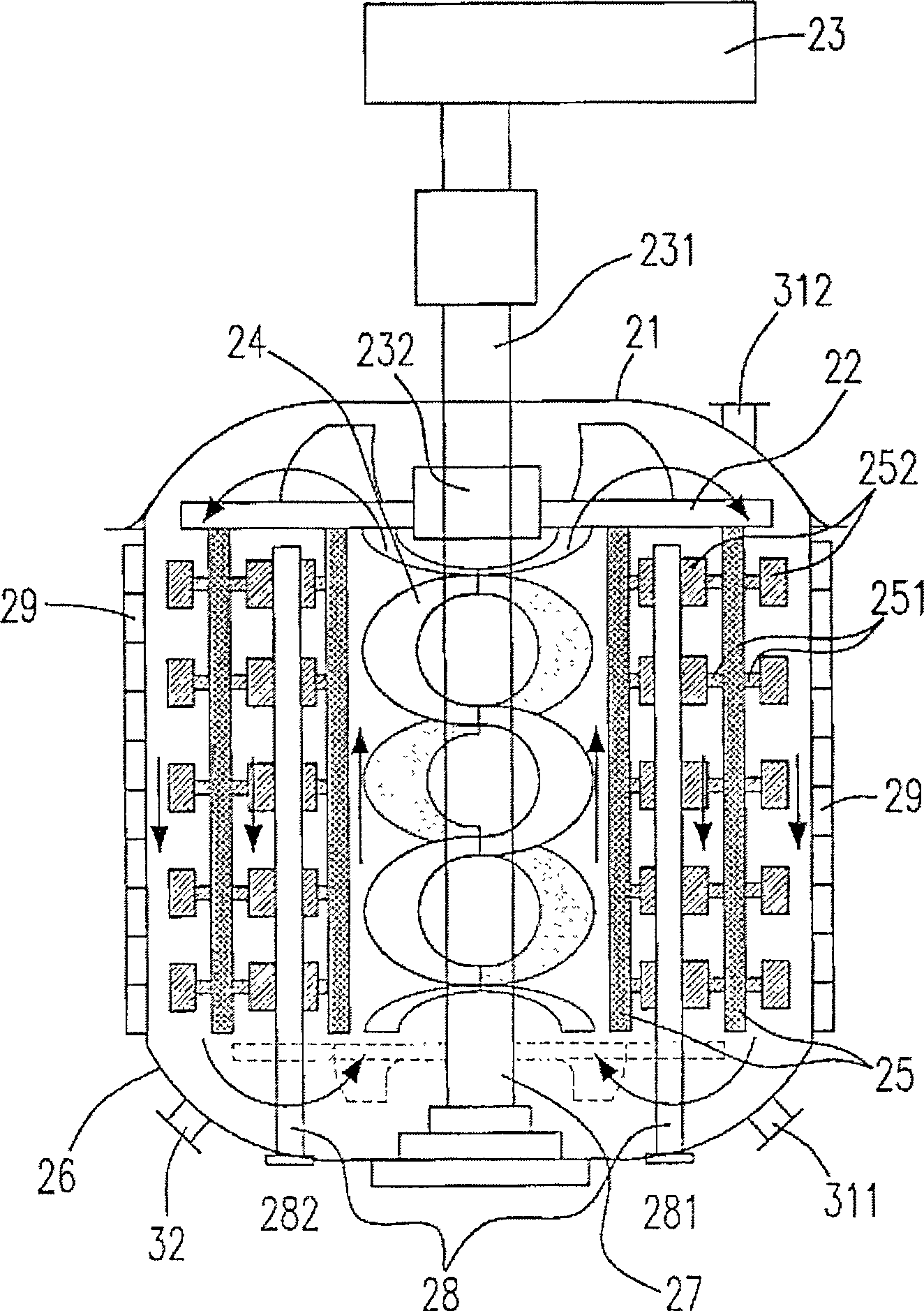

[0056] see figure 2 , which is a schematic diagram of a preferred polymer polymerization tank of the present invention. Among them, the reaction tank is composed of a tank body cover 21, a crossbeam 22, a frequency conversion motor 23, a pair of ribbon-shaped stirring wings 24, a scraper pillar 25, a liftable tank body 26, a stirring central axis 27, a tank The inner interlayer 28 and a groove-side interlayer 29 are formed.

[0057] When desiring to carry out macromolecule polymerization reaction, tank body 26 can rise to such as figure 2 As shown, it is closely combined with the upper cover 21 of the tank body. At this time, the stirring central shaft 27 fixed inside the tank body, the plug at the top will also be inserted into the shaft seal 232 of the transmission shaft 231 of the frequency conversion motor 23, so that the stirring central shaft 27 is in contact with the tank body. Combined and fixed on the crossbeam 22, it is used to balance the inertial centrifugal fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com