A kind of fe-36ni invar alloy material with excellent thermoplasticity and preparation method thereof

A technology of Invar alloy and fe-36ni, applied in the field of Fe-36Ni Invar alloy material and its preparation, can solve the problems of unstable product quality, prominent contradiction between supply and demand, and high production cost, so as to improve production efficiency and product quality, The effect of reducing production costs and expanding production varieties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical solutions and advantages of the present invention clearer, the present invention will be further described below through examples. In addition, the specific embodiments herein are only used to explain the present invention, not to limit the present invention. On the contrary, the invention covers all such substitutions and modifications within the scope of the invention as defined by the claims.

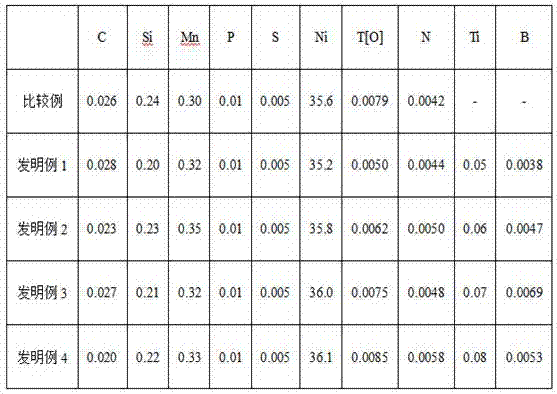

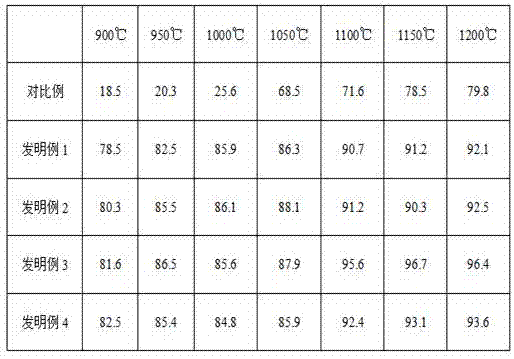

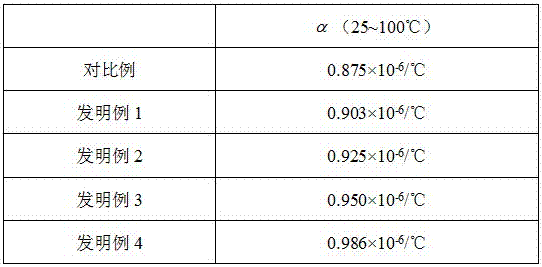

[0030] The Fe-36Ni Invar alloy material with the required composition is smelted in a vacuum induction furnace. The melting temperature is 1500~1530°C. First add an appropriate amount of Ti, after refining for 2 minutes, then add an appropriate amount of B, and refine for 1 minute. Cool the melt until the temperature drops. To 1450~1460°C, cast the melt under vacuum conditions to obtain a cylindrical ingot with a diameter of 70mm. Under the protective atmosphere, the ingot is heated to 1200°C within 3 hours, forged after 2 hours of heat preserva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com