A kind of low chromium and low nickel duplex stainless steel and preparation method thereof

A technology of duplex stainless steel and steel ingot, applied in the field of iron and steel materials, can solve the problems of poor thermoplasticity of duplex stainless steel, and achieve the effect of solving poor thermoplasticity, good weldability and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

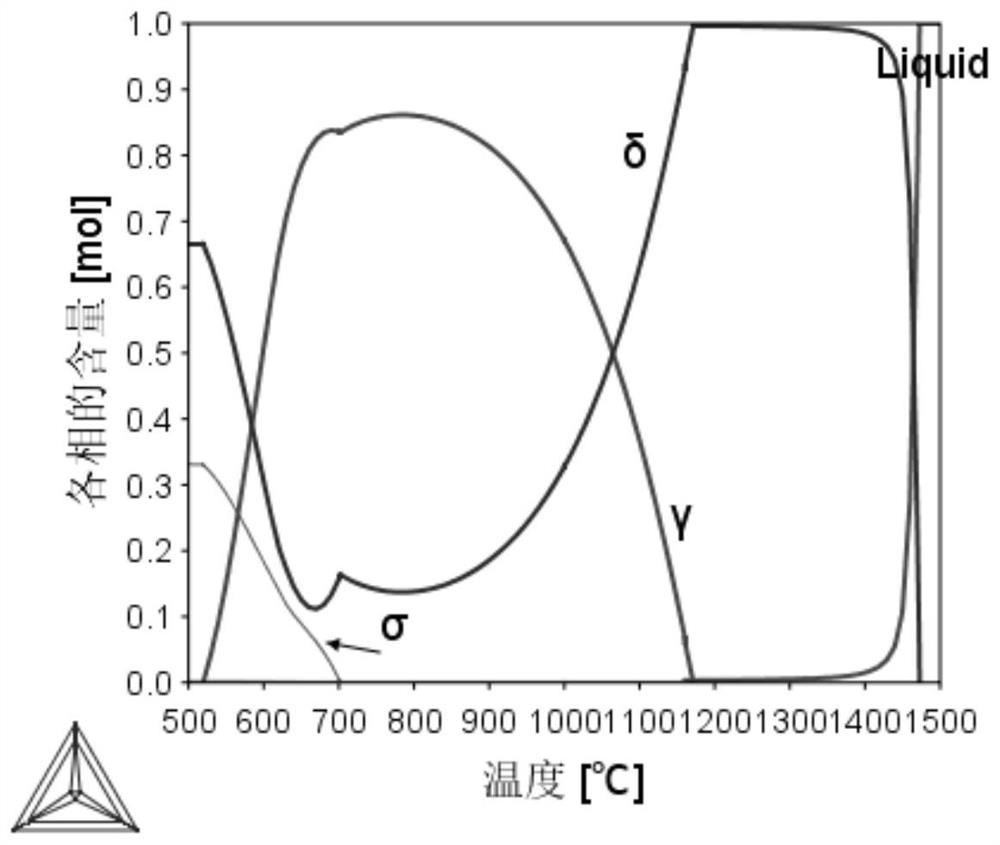

[0039] The low-chromium and low-nickel duplex stainless steel of this embodiment has the following composition by mass percentage: C 0.01%, Si 0.3%, Mn 10%, P≤0.01%, S≤0.01%, Al 0.5%, Cr15%, Ni 0.4 %, B 0.01%, the balance is Fe and unavoidable impurities, the equilibrium phase diagram of the duplex stainless steel is calculated by Thermo-Calc software as follows figure 1 shown.

[0040] The preparation method of the low-chromium and low-nickel duplex stainless steel comprises the following steps:

[0041] After comprehensive measurement and calculation and melting of ingredients, it is cast into steel ingots; the steel ingots are hot forged at 1120°C into 40mm thick forging billets, and cooled to room temperature in water; the forging billets are homogenized at 1250°C for 6 hours; the homogenized billets are Hot rolling at 1200°C, the final rolling temperature is 1050°C, ensuring that the single-pass reduction rate of hot rolling is not more than 30%, forming a hot-rolled she...

Embodiment 2

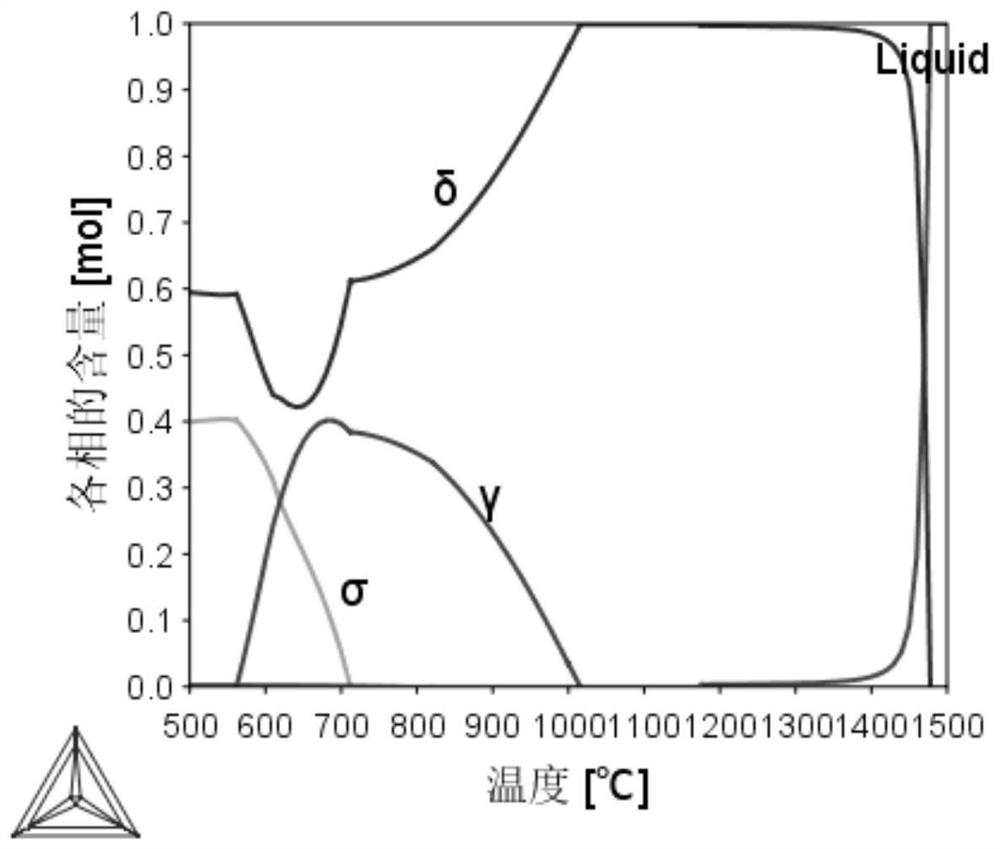

[0043] The low-chromium and low-nickel duplex stainless steel of this embodiment has the following composition by mass percentage: C 0.02%, Si 0.3%, Mn 10%, P≤0.01%, S≤0.01%, Al 0.8%, Cr19%, Ni 0.4 %, B 0.01%, the balance is Fe and unavoidable impurities, the equilibrium phase diagram of the duplex stainless steel is calculated by Thermo-Calc software as follows figure 2 shown.

[0044] The preparation method of the low-chromium and low-nickel duplex stainless steel comprises the following steps:

[0045] After comprehensive measurement and calculation and melting of ingredients, it is cast into steel ingot; the steel ingot is hot-forged at 1050°C to form a 60mm thick forging billet, and then water-cooled to room temperature; the forging billet is homogenized at 1200°C for 8 hours; Hot rolling at 1150°C, the final rolling temperature is 950°C, ensuring that the reduction rate of a single pass of hot rolling is not more than 30%, forming a hot-rolled sheet with a thickness of...

Embodiment 3

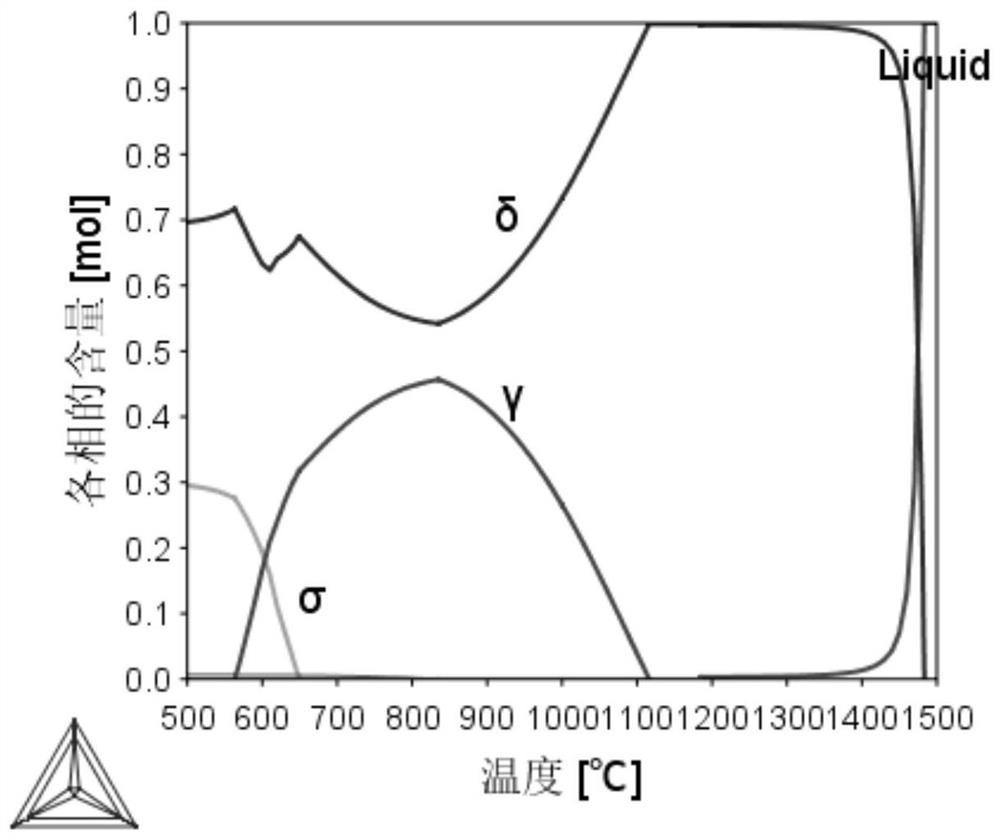

[0047] The low-chromium and low-nickel duplex stainless steel of this embodiment has the following composition by mass percentage: C 0.03%, Si 0.3%, Mn 8%, P≤0.01%, S≤0.01%, Al 1.1%, Cr16%, Ni 0.5 %, B 0.01%, the balance is Fe and unavoidable impurities, the equilibrium phase diagram of the duplex stainless steel is calculated by Thermo-Calc software as follows image 3 shown.

[0048] The preparation method of the low-chromium and low-nickel duplex stainless steel comprises the following steps:

[0049] After comprehensive measurement and calculation and melting of ingredients, it is cast into steel ingot; the steel ingot is hot-forged at 1070°C to form a 55mm thick forging billet, and water cooled to room temperature; the forging billet is homogenized at 1220°C for 7 hours; Hot rolling at 1180°C, the final rolling temperature is 1000°C, ensuring that the reduction rate of a single pass of hot rolling is not more than 30%, forming a hot-rolled sheet with a thickness of 4.2mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com