Distributing element

An appliance and wiring technology, applied in the direction of electrical components, circuits, connections, etc., can solve problems such as poor contact, and achieve the effect of increasing the degree of freedom of design and reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

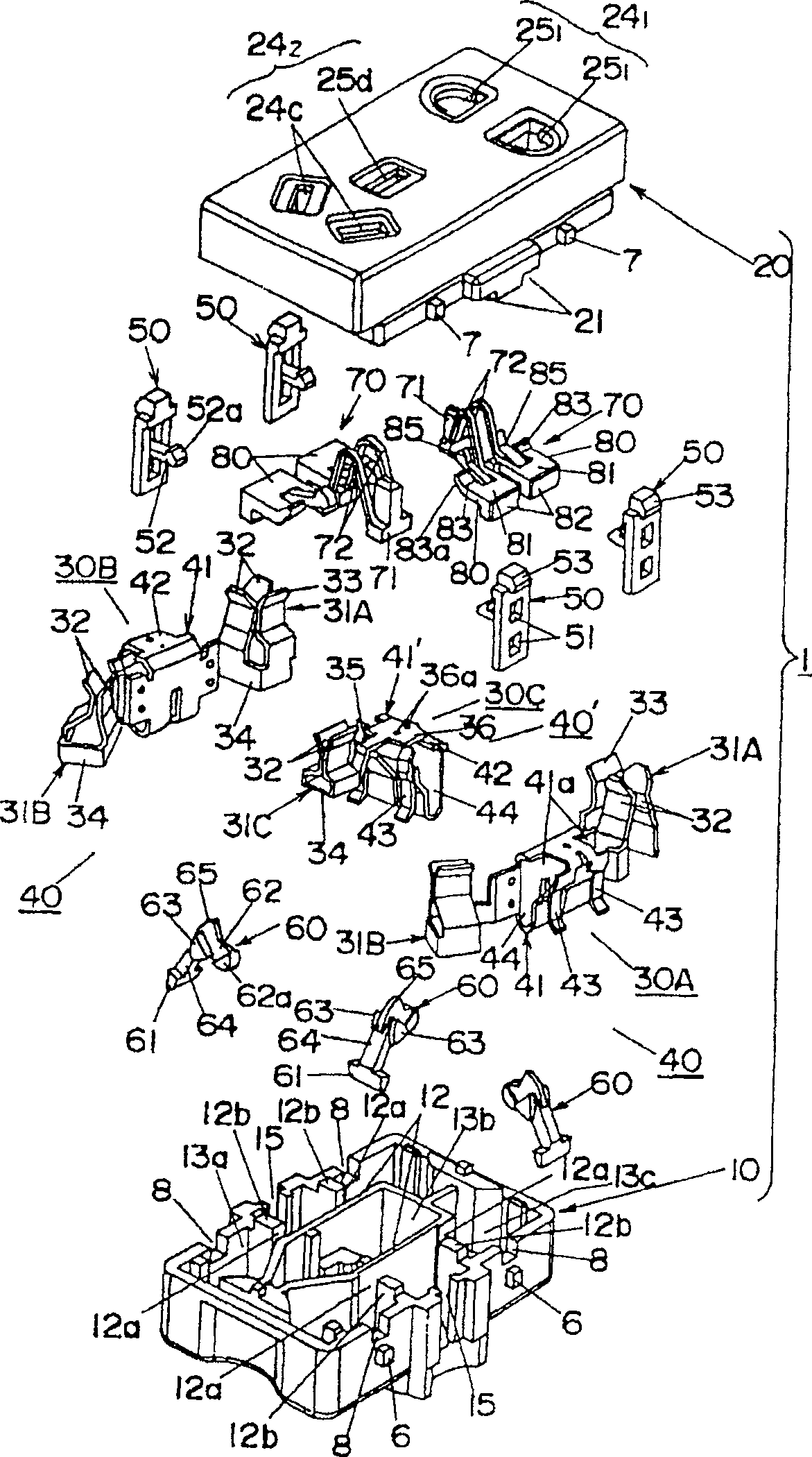

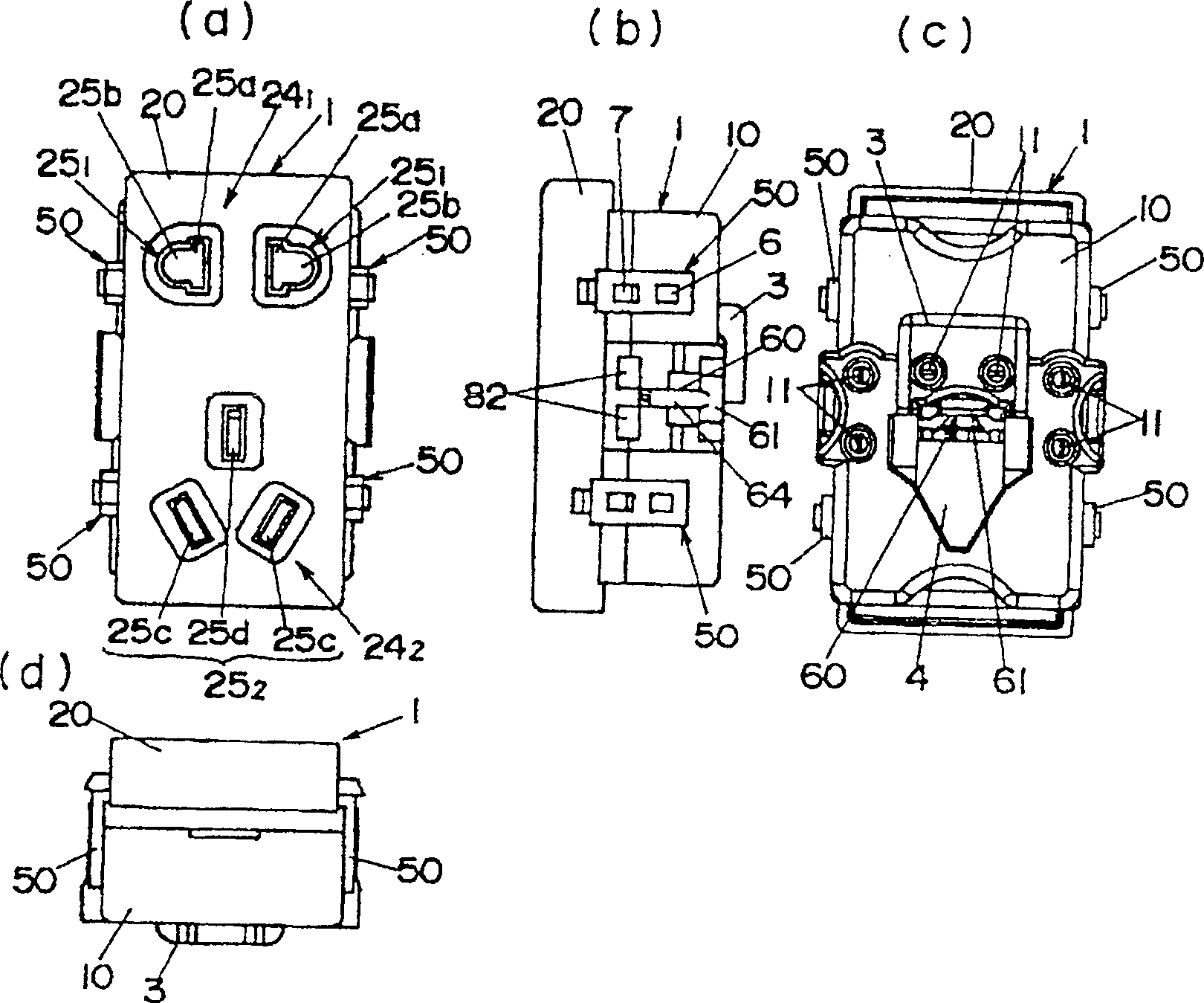

[0032] The socket of this embodiment is as figure 1 and figure 2 As shown, there is an appliance body 1, which is composed of the following components. The body 10 is formed into a rectangular parallelepiped with an open front using a thermosetting synthetic resin with excellent tracking resistance; and the cover 20 is also made of an anti-leakage Thermosetting synthetic resin excellent in tracking property is formed into a rectangular parallelepiped with an open back.

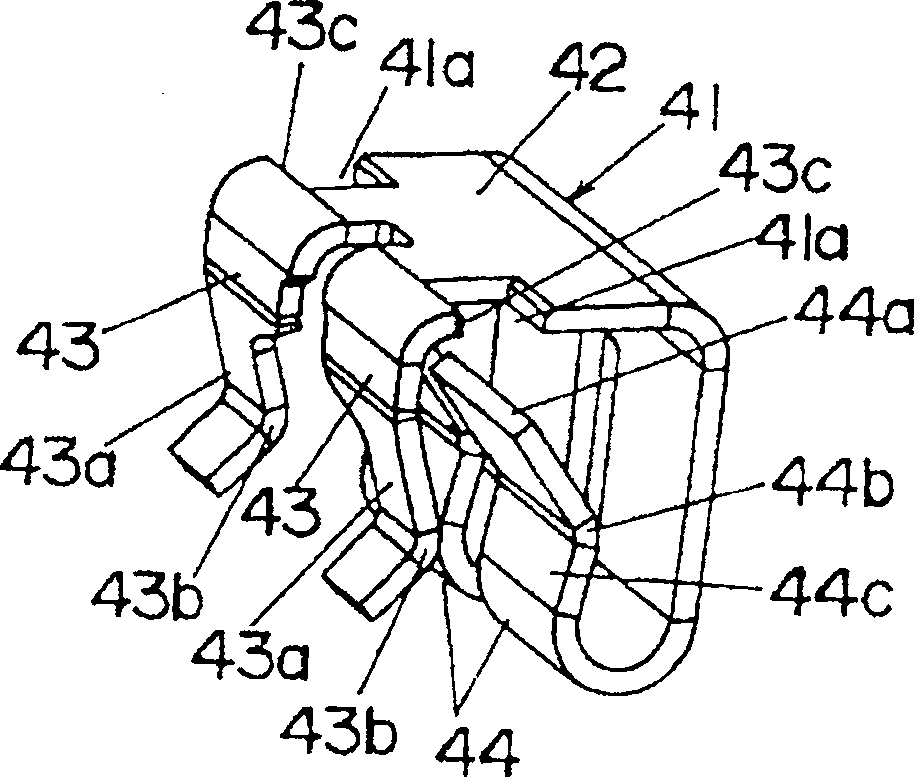

[0033] The body 10 divides the inner space into three parts by a plurality of partition walls 12 disposed along the longitudinal direction. Again, partition walls (not shown) are also formed in the lid 20. After the body 10 and the lid 20 are combined, the internal space of the appliance body 1 is divided into three independent chambers (storage chambers) by the partition wall 12 between the body 10 and the lid. 13a, 13b, 13c). Moreover, the storage chambers 13a and 13b at both ends are subdivided into thr...

Embodiment 2

[0058] In the first embodiment, the connection with the terminal portion 40 is released, and the display member 80 is returned from the protruding position to the non-protruding position by pressing the display portion 82 by hand after pulling out 101 from the wire insertion hole 11 . However, the present embodiment is characterized in that the display member 80 is returned from the protruded position to the non-protruded position by the release button 60 that releases the connection between the electric wire 101 and the terminal portion 40, and other structures are the same as in the first embodiment. Therefore, the same reference numerals are assigned to the same components as in the first embodiment, and descriptions and illustrations are omitted.

[0059] In this embodiment, the release button 60 is as Figure 10 As shown, an approximately triangular driving piece 66 protruding parallel to the end surface of the connecting portion 64 and the support portion 65 is provided,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com