Process for fermentative production of L-methionine

一种甲硫氨酸、菌株的技术,应用在制造L-甲硫氨酸领域

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1: Cloning of Basic Vector pKP228

[0059] In order to place the yjeH gene under the control of a constitutive promoter, first construct a basic vector containing the constitutive GAPDH promoter of the gapA gene used by Escherichia coli glyceraldehyde 3-dehydrogenase. For this purpose, use primers

[0060] GAPDHfw: (SEQ ID NO: 3)

[0061] 5'GTC GAC GCG T GA GGC GAG TCA GTC GCG TAA TGC 3’

[0062] Mlu I

[0063] GAPDHrevl: (SEQ ID NO: 4)

[0064] 5'GAC CTT AAT TAA GAT CT C ATA TAT TCC ACC AGC TAT TTG TTA G 3’

[0065] PacI Bgl II

[0066] and chromosomal DNA polymerase chain reaction of Escherichia coli strain W3110 (ATCC27325). The resulting DNA fragments were purified by agarose gel electrophoresis and then separated (Chia Quick Gel Extraction Kit, Chiagen, Hilton, Germany). Afterwards, the fragment was treated with restriction enzymes PacI and MluI and cloned into the vector pACYC184-LH, similarly with PacI / NluI (August 18, 1995 under t...

Embodiment 2

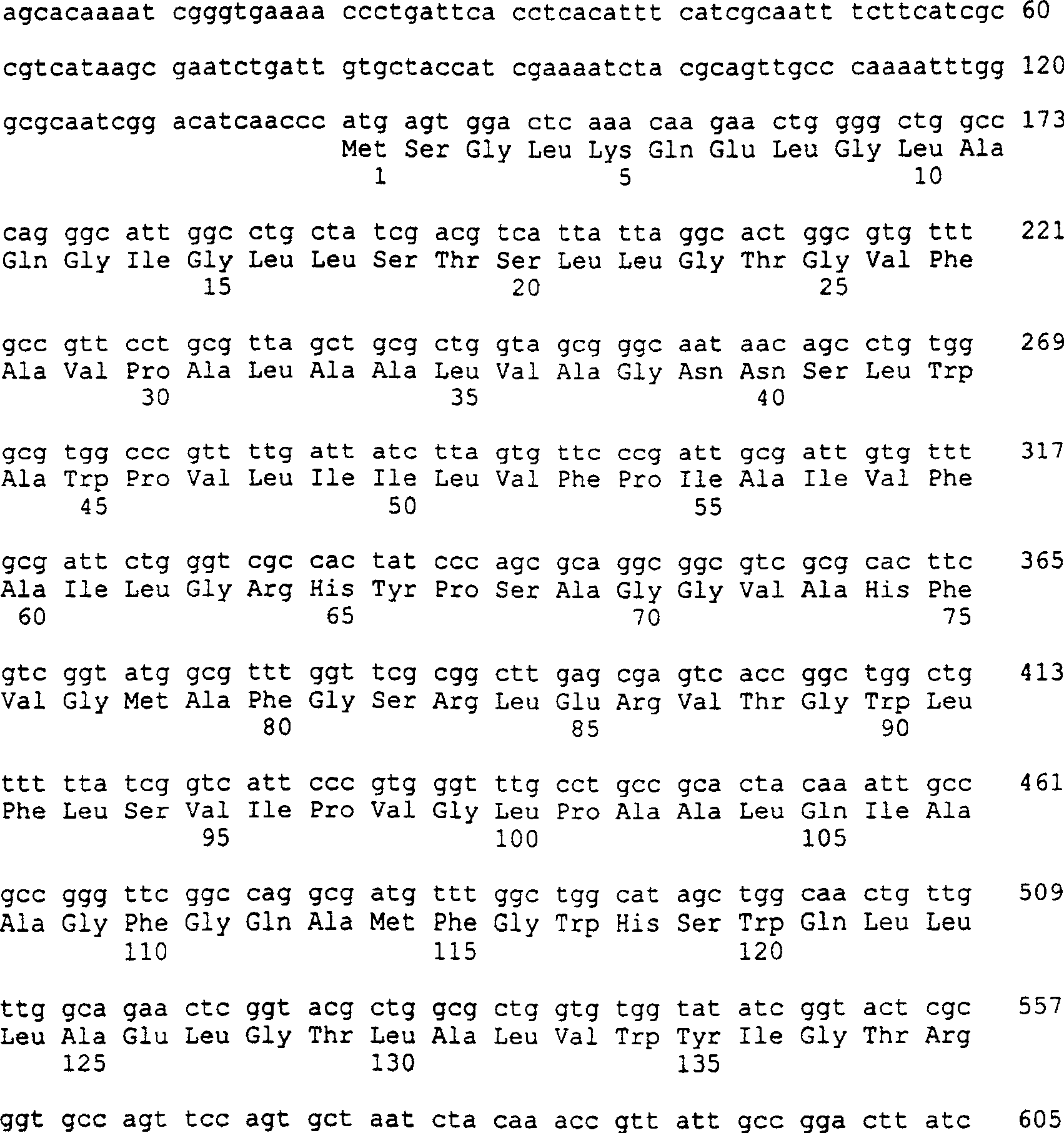

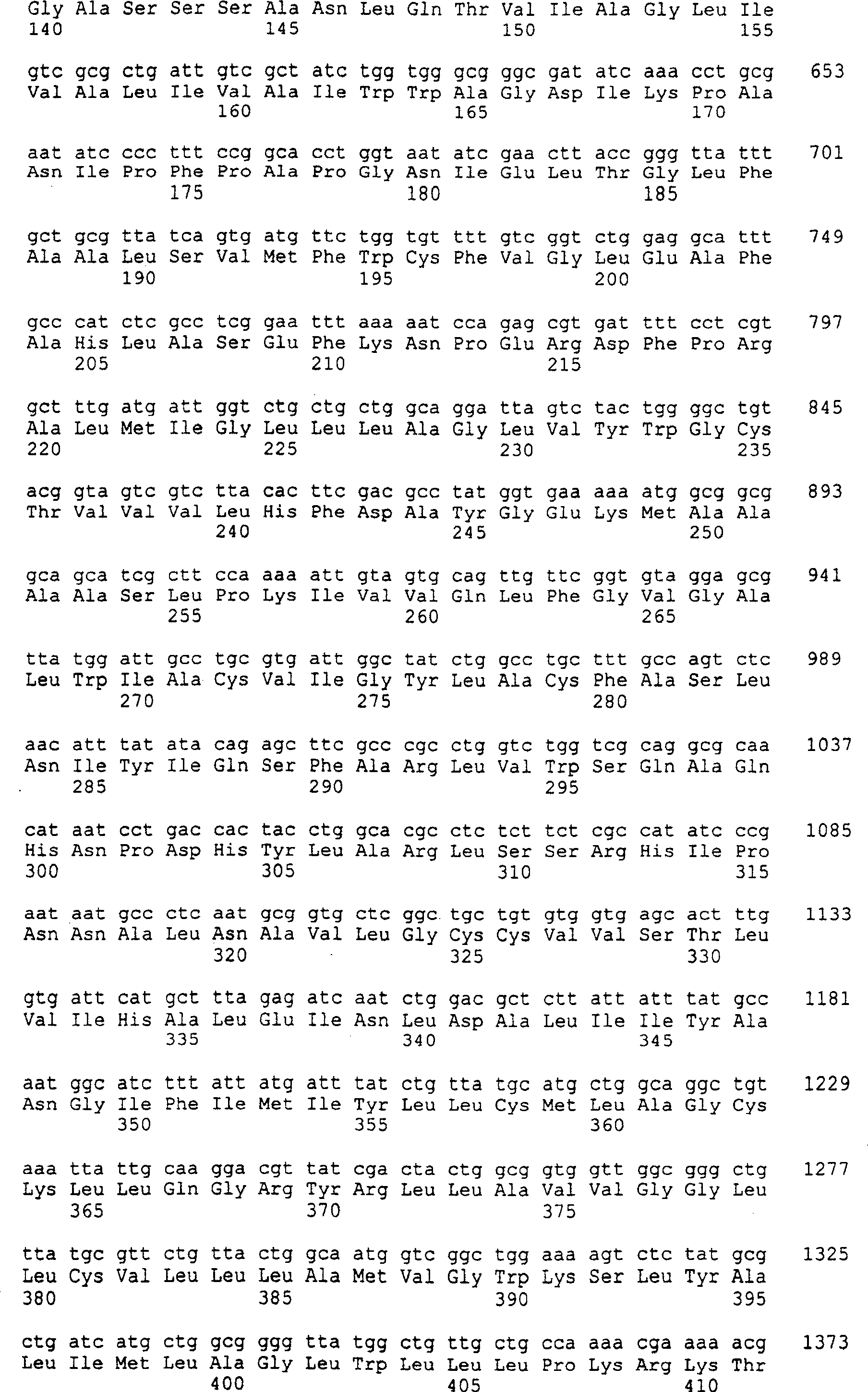

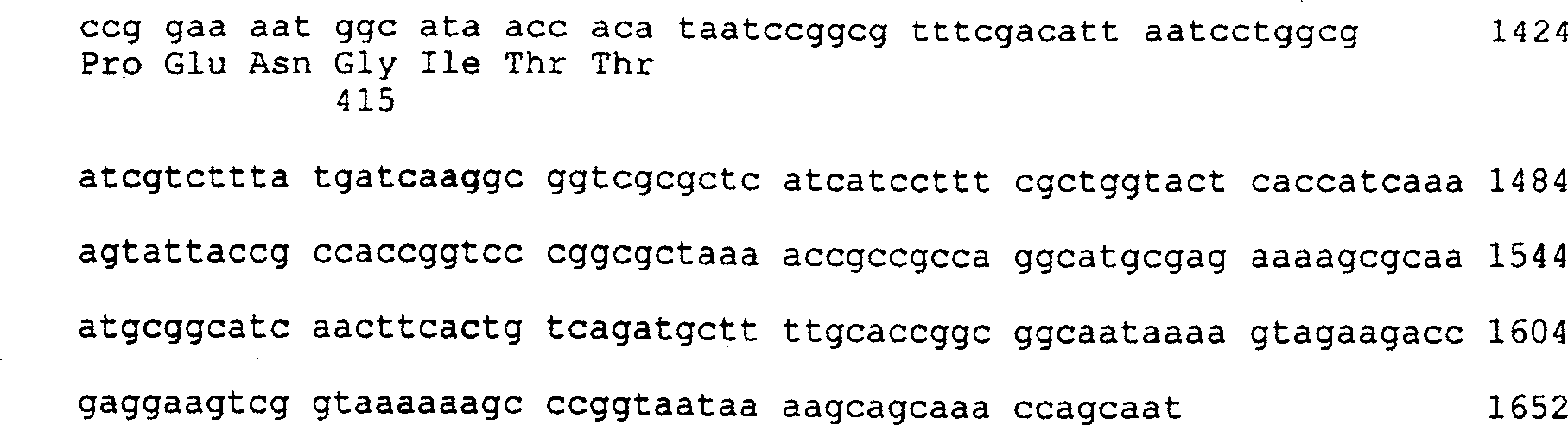

[0067] Embodiment 2: Cloning of yjeH gene

[0068] The yjeH gene from E. coli W3100 strain was amplified by polymerase chain reaction. Use oligonucleotides

[0069] yjeH-fw: (SEQ ID NO: 5)

[0070] 5'-ATT GCT GGT TTG CTG CTT-3'

[0071] yjeH-rev: (SEQ ID NO: 6)

[0072] 5’-AGC ACA AAA TCG GGT GAA-3’

[0073] As specific primers and as template chromosomal DNA of E. coli strain W3110 (ATCC27325) was used. The prepared DNA fragments were purified and separated by agarose gel electrophoresis (Chia Quick Gel Extraction Kit, produced by Chiagen, Hilton, Germany). Cloning was performed by blunt-end ligation with a BglII-cleaved pKP228 vector whose 5'-overhang was filled in with Klenow enzyme. The procedure is to place the yjeH gene downstream of the GAPDH promoter in an appropriate manner so that transcription is initiated from there. The prepared vector was named pKP450.

Embodiment 3

[0074] Example 3: Combination of the yjeH gene with a feedback resistant metA allele

[0075] By polymerase chain reaction using template pKP466 (described in patent application DE-A-10247437) and primers

[0076] metA-fw: (SEQ ID NO: 7)

[0077] 5”-CGC CCA TGG CTC CTT TTA GTC ATT CTT-3'

[0078] NCOI

[0079] metA-rev: (SEQ ID NO: 8)

[0080] 5'-CGC GAG CTC AGT ACT ATT AAT CCA GCG-3’

[0081] SacI

[0082] The metA allele encoding a feedback-resistant O-homoserine transsuccinylase described in the patent application DE-A-10247437 of the same applicant on October 11, 2002 was amplified.

[0083] In this procedure terminal cleavage sites for the restriction endonucleases NcoI and SacI are generated. The resulting DNA fragment was digested with the same endonuclease, purified and cloned into the NcoI / SacI cleaved pKP450 vector. The resulting plasmid was named pKP451.

[0084] To create a control plasmid containing the metA allele but no yjeH gen...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap