Optical false proof nondestructive testing apparatus

A non-destructive testing and optical anti-counterfeiting technology, applied in the field of applied optics, can solve the problems of high production cost, complex anti-counterfeiting label production process, sample damage, etc., and achieve the effect of improving service life, improving operation safety, and improving use efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Switch 1 is a light touch electronic switch with a spring, the model is KFC-A03-04.

[0029] The battery 2 is a 3V lithium battery.

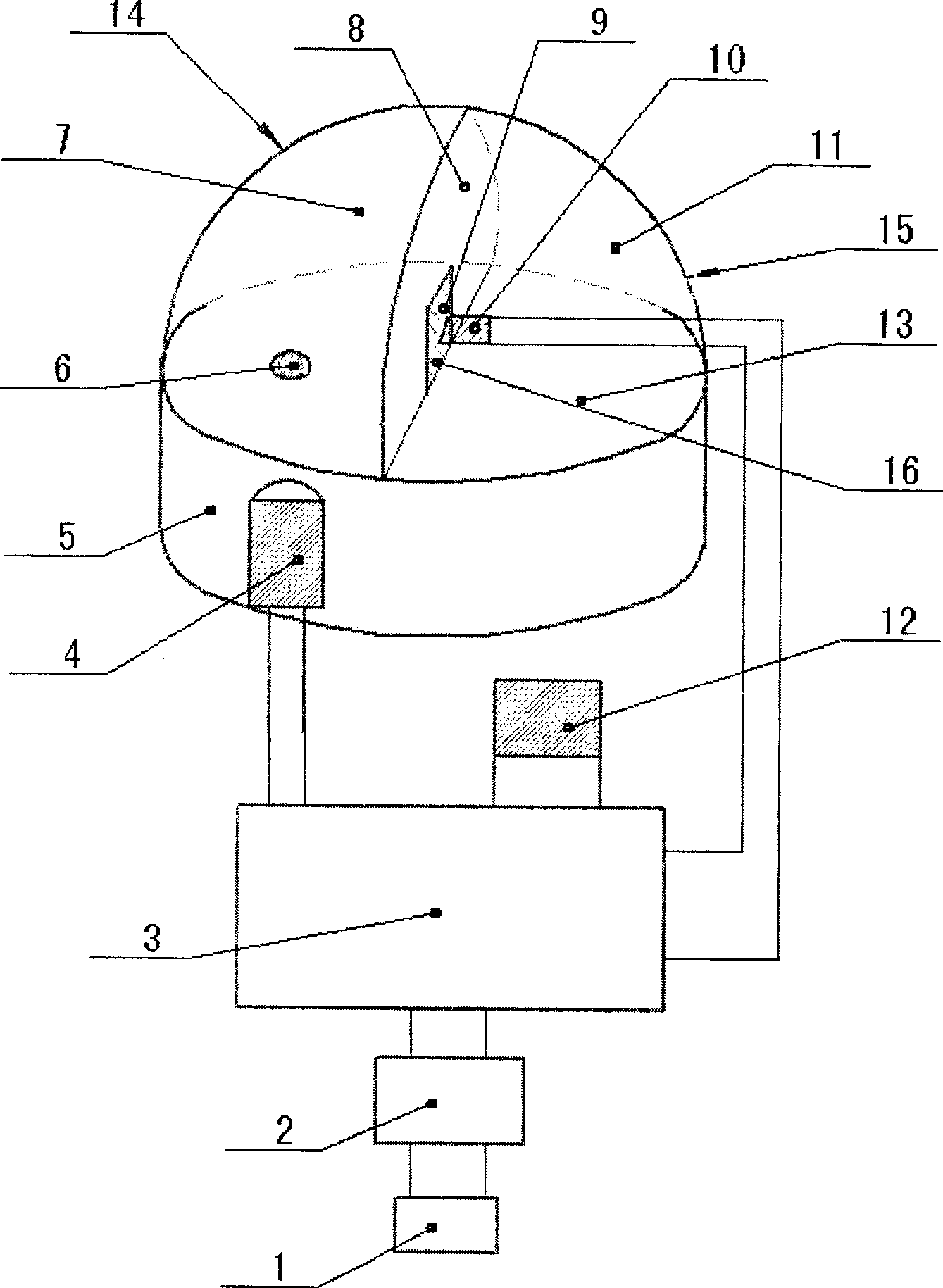

[0030] The electronic circuit board 3 is an electronic circuit board with six pins, the positive and negative poles of the exciting light source 4 are connected to the a and b pins respectively, the positive and negative poles of the photodetector 10 are connected to the c and d pins respectively, and the output device 12 The positive and negative poles are connected to the e and f pins respectively, such as figure 1 shown.

[0031] The excitation light source 4 is a semiconductor laser (LD). When the room temperature is 20°C, the central wavelength of the emitted laser is 980nm, and the bandwidth of the emitted laser peak is 1nm-3nm. The power is 200mW.

[0032] Exciting light source bracket 5 is a circular plate structure with a certain thickness made of red copper material. There is a through hole on the left side of the circular to...

Embodiment 2

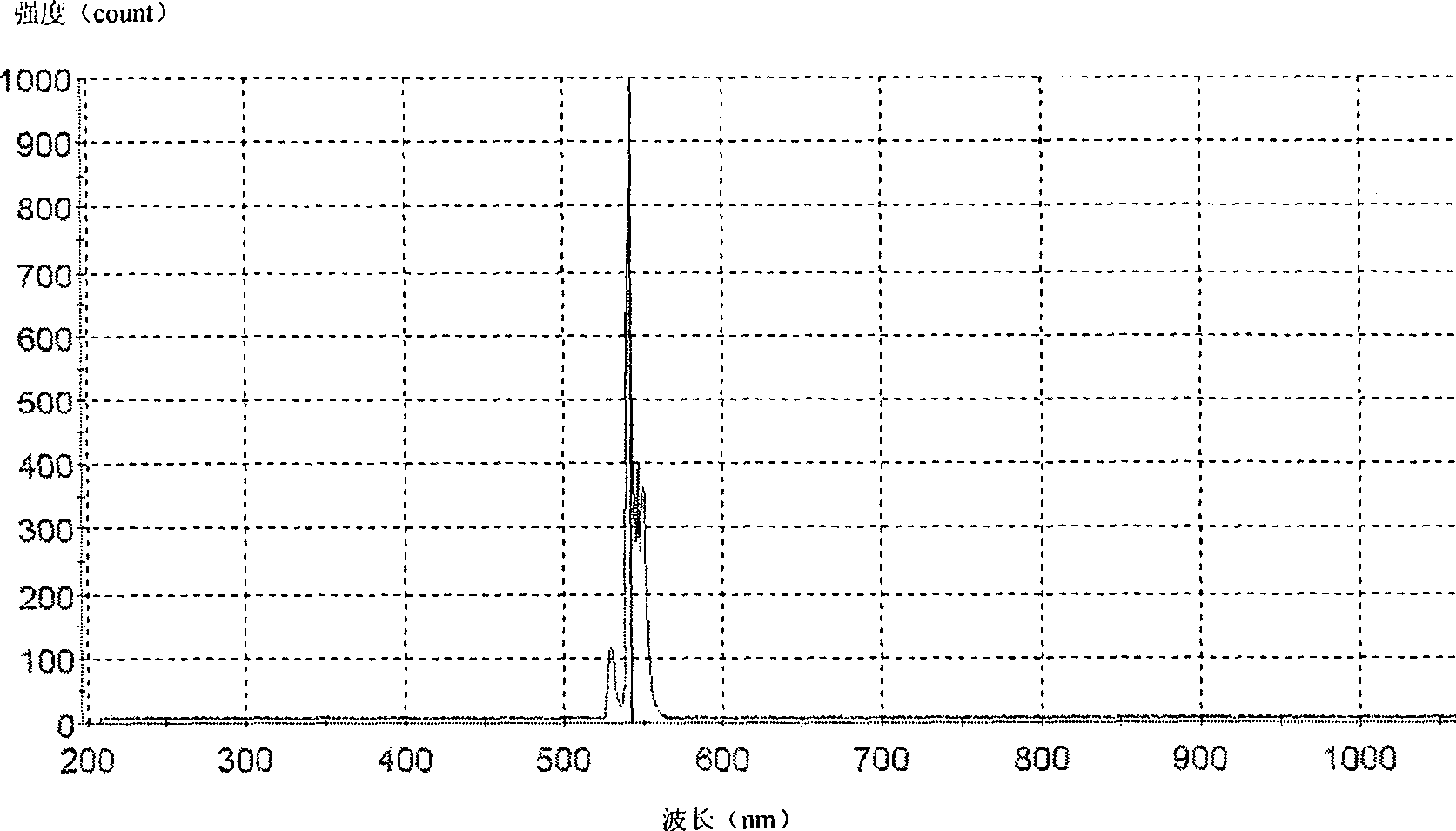

[0043] The only difference between this embodiment and Embodiment 1 is: the excitation light source 4 adopts a light-emitting diode (LED), and the central wavelength of its emitted light is the same as the absorption wavelength of the infrared (up-conversion) fluorescent material, which is 980nm, and the bandwidth of the emitted laser peak It is 5nm-10nm.

Embodiment 3

[0045] The difference between this embodiment and embodiment 1 is:

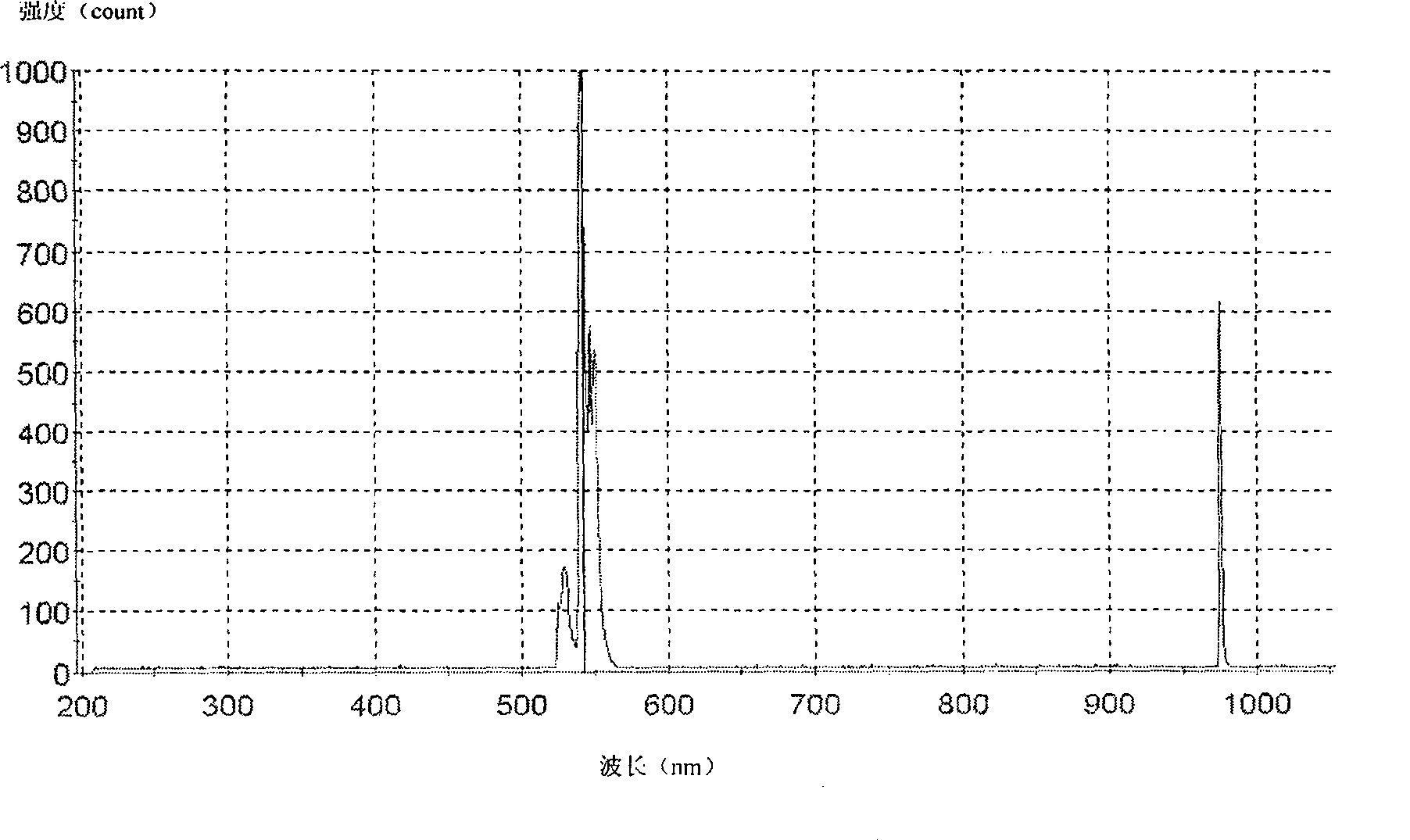

[0046] The excitation light source 4 is a semiconductor laser (LD). At a room temperature of 20°C, the central wavelength of the emitted laser is 973nm, the bandwidth of the emitted laser peak is 1nm-3nm, and the power is 200mW. The halide material system doped with rare earth elements uses europium (Eu 3+ ) Yttrium (Yb 3+ ) co-doped silicate, after absorbing infrared light with a wavelength of 973nm, the emitted fluorescence characteristic line is visible orange light with a wavelength of 593nm.

[0047] The reflective film on the inner cavity wall of the left sub-chamber cover 14 has high reflectivity to the 973nm near-infrared light emitted by the excitation light source 4, and has high reflectivity to the 593nm visible fluorescence emitted by the infrared (up-conversion) fluorescent material.

[0048] The reflective film on the inner cavity wall of the right sub-chamber cover 15 has a high reflectivity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com