Double pressure medium cylinder device and loading device of textile machine having the device

A technology of pressure medium and cylinder device, applied in spinning machine, textile and papermaking, drafting equipment, etc., can solve the problems of long cylinder structure, pipe breakage, assembly cost, etc., saving space, preventing breakage danger, and reliable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

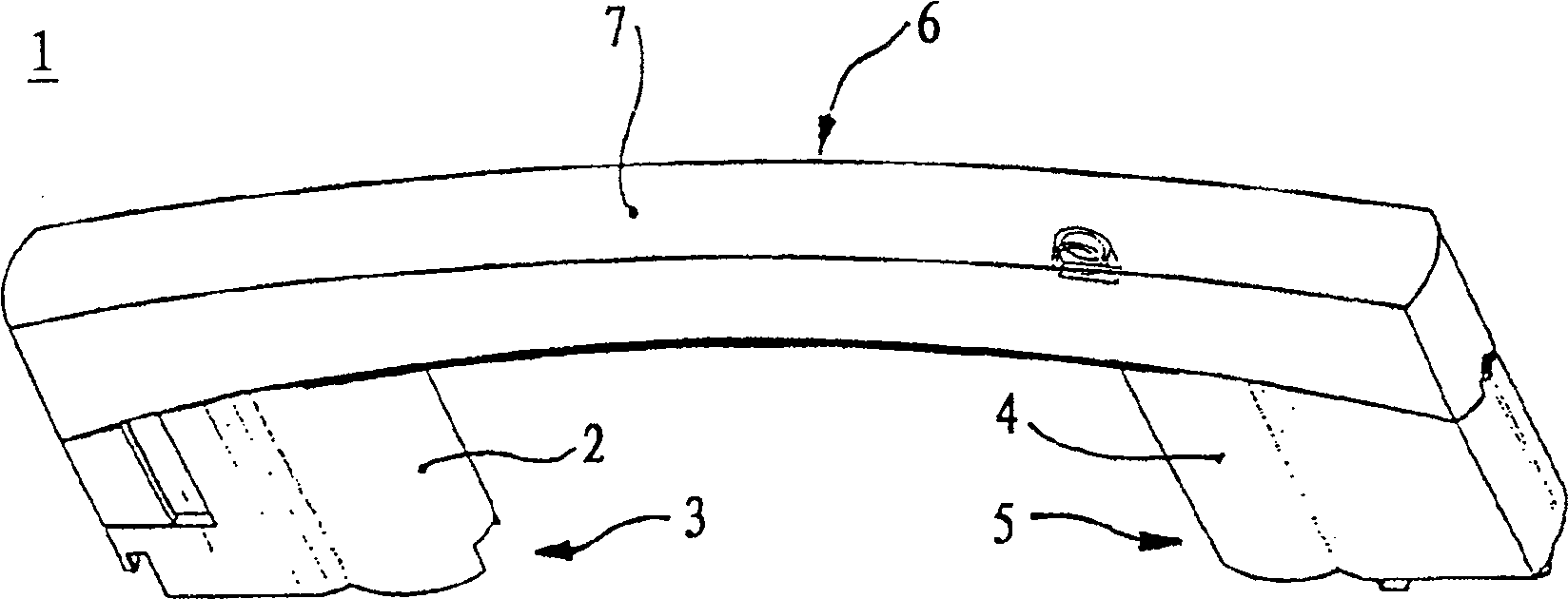

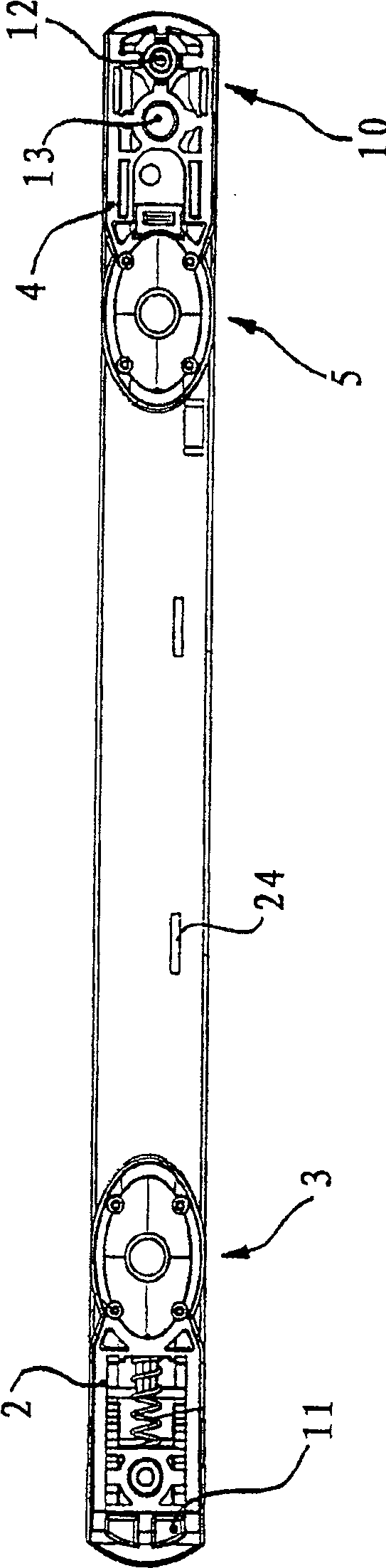

[0024] according to figure 1 The dual pressure medium cylinder device has a substantially U-shaped housing element 1, the first arm part 2 of which constitutes a cylinder block for a pressure medium cylinder 3, whereas the opposite second arm part 4 forms a cylinder block for the other Cylinder block of the pressure medium cylinder 5 . Furthermore, a strut 6 is provided, which connects the first pressure medium cylinder 3 and the second pressure medium cylinder 5 at the bottom of the cylinder. In this case, two pressure medium cylinders 3 and 5 are arranged axially parallel and spaced apart from one another. The struts 6 are formed by the hollow center 7 of the common U-shaped housing element.

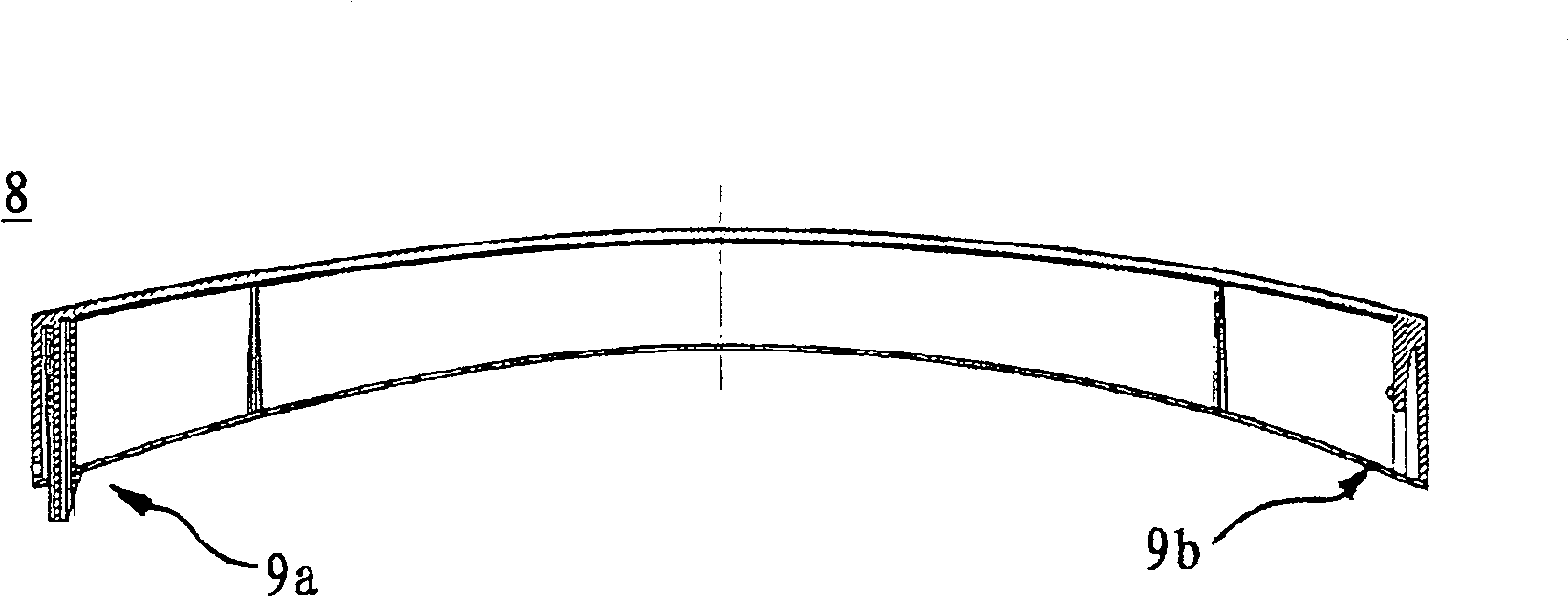

[0025] according to figure 2 , the U-shaped housing element 1 is closed with a strip-type cover 8 shown separately here, which is attached to the middle part 7 of the U-shaped housing element 1 . Its attachment to the U-shaped housing element 1 takes place via form-locking connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com