Two-way automatic getting in and out mounting belt

An automatic, two-way motor technology, applied in pasting, decorative arts, transportation and packaging, etc., can solve the problems of high labor intensity, troublesome cleaning, slow hand movements, etc., to reduce labor intensity, save mounting time, and improve the quality of mounting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

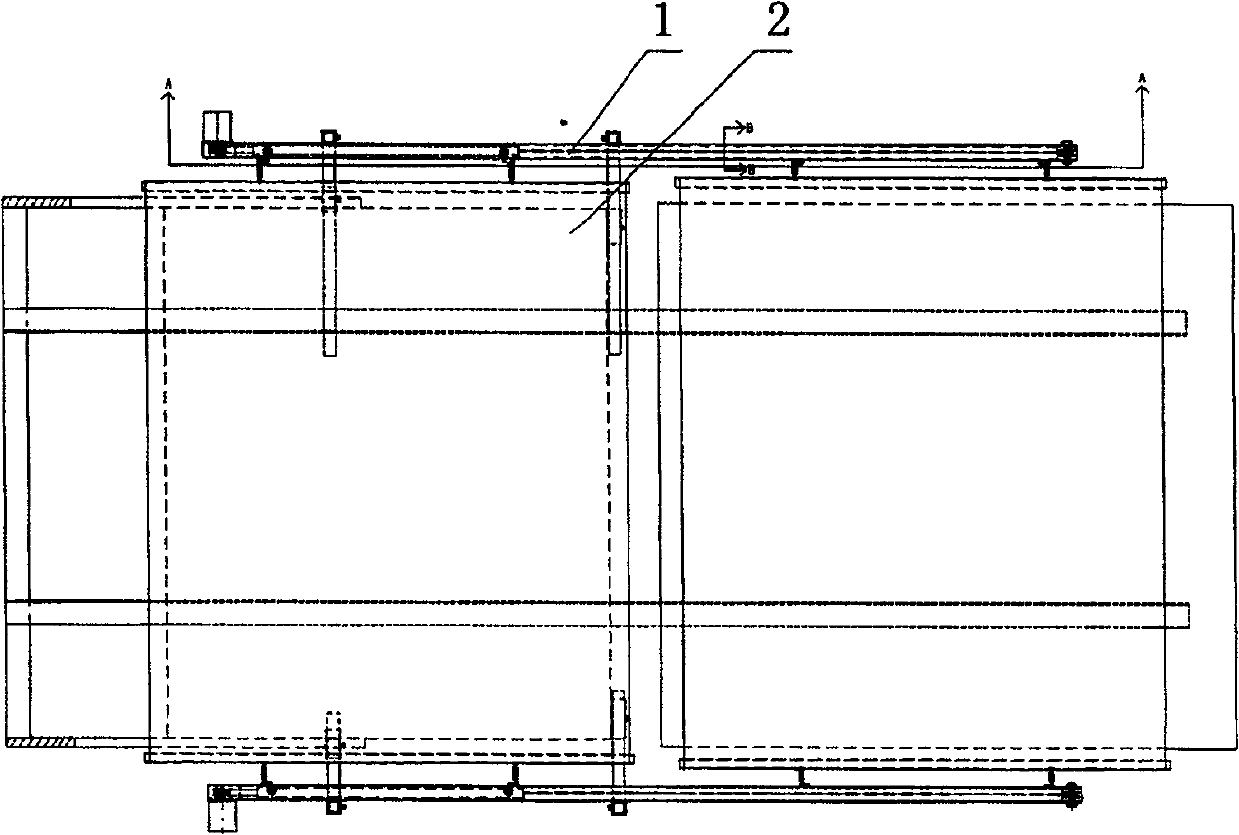

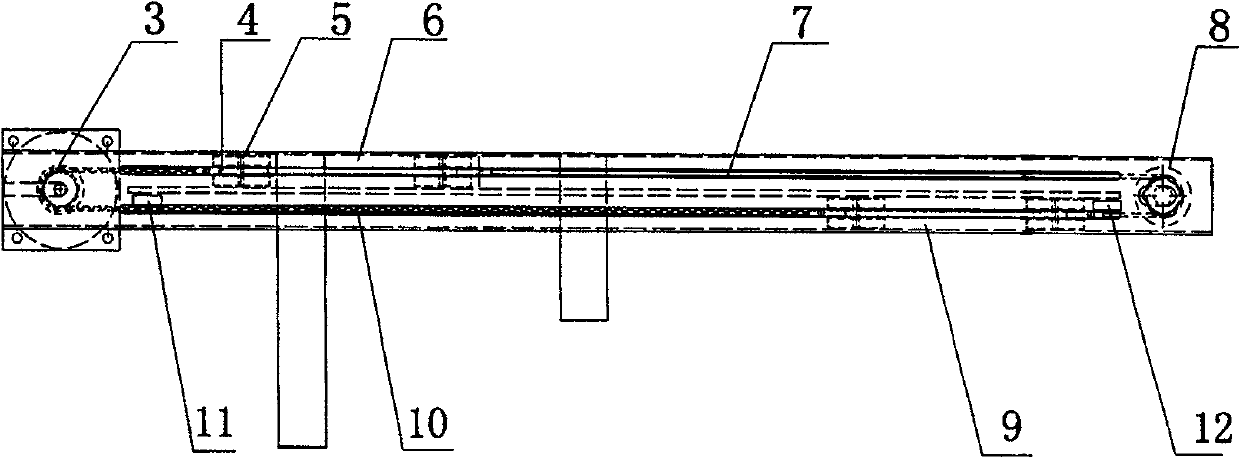

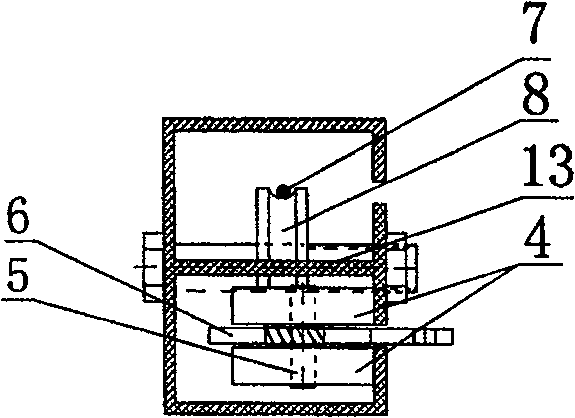

[0017] See figure 1 , figure 2 , two-way automatic entry and exit mounting belt, the device is composed of two-way entry and exit rail 1, mounting tape 2, upper moving plate 6, lower moving plate 9, timing belt 10, steel wire rope 7, two-way motor 3, hook wheel 8, two two-way entry and exit rails 1 set in parallel with two mounting tapes 2 set in between; see Figure 4 , Mounting tape 2 ends are provided with sleeve pipe 15, sleeve pipe 15 connects tension spring 14, and tension spring 14 is connected with the connecting ear of moving plate side; See figure 2 , the moving plate is arranged in upper and lower layers, one side of the upper moving plate 6 is connected to the synchronous belt 10, and the other side is connected to the steel wire rope 7; , then connect the lower moving plate 9, the other side of the lower moving plate 9 is connected with the steel wire rope 7, the steel wire rope 7 kisses and rolls with the hook wheel 8 located at the other end of the two-way i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com