Detecting equipment and detecting method for metal ceiling system strength

A detection equipment, metal technology, applied in elastic testing, testing of machine/structural components, using stable tension/pressure to test the strength of materials, etc., can solve problems such as system vibration, damage, deformation, etc., to achieve more detection methods Scientific and complete, reliable test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Embodiment one is to carry out static load and dynamic load test to the C300 specification strip of a certain manufacturer, the specific method steps are as follows:

[0075] (1) Install and debug the sample.

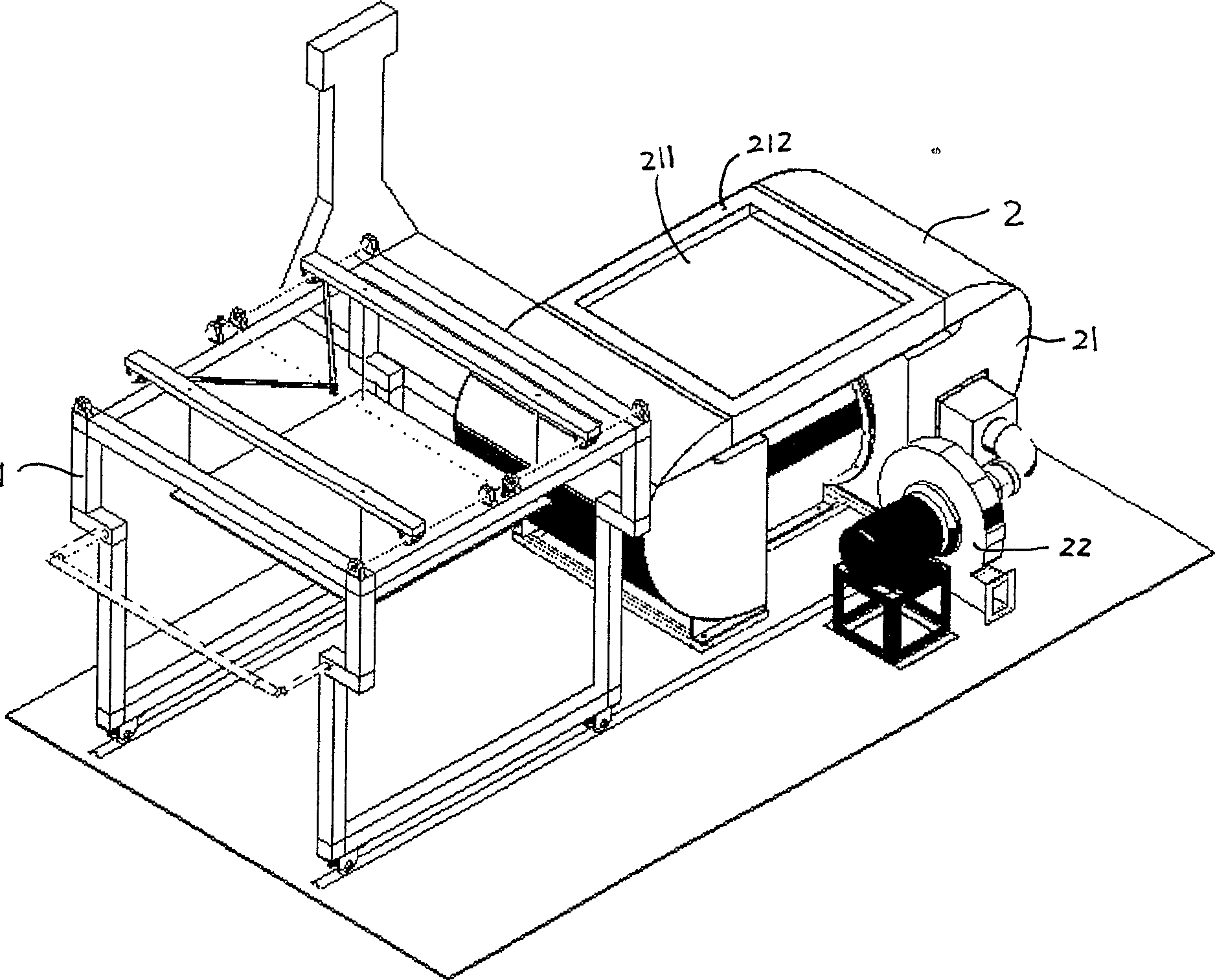

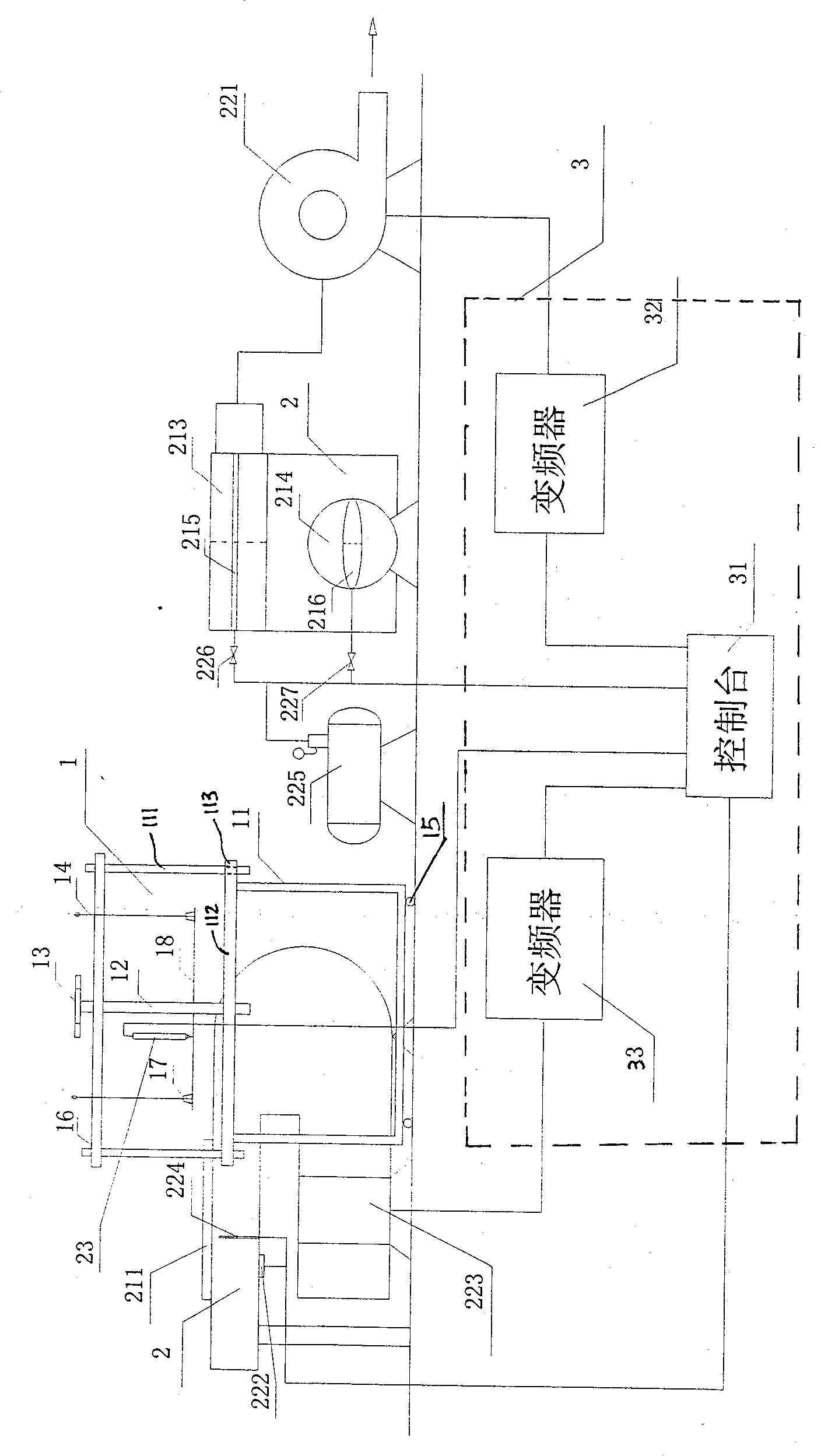

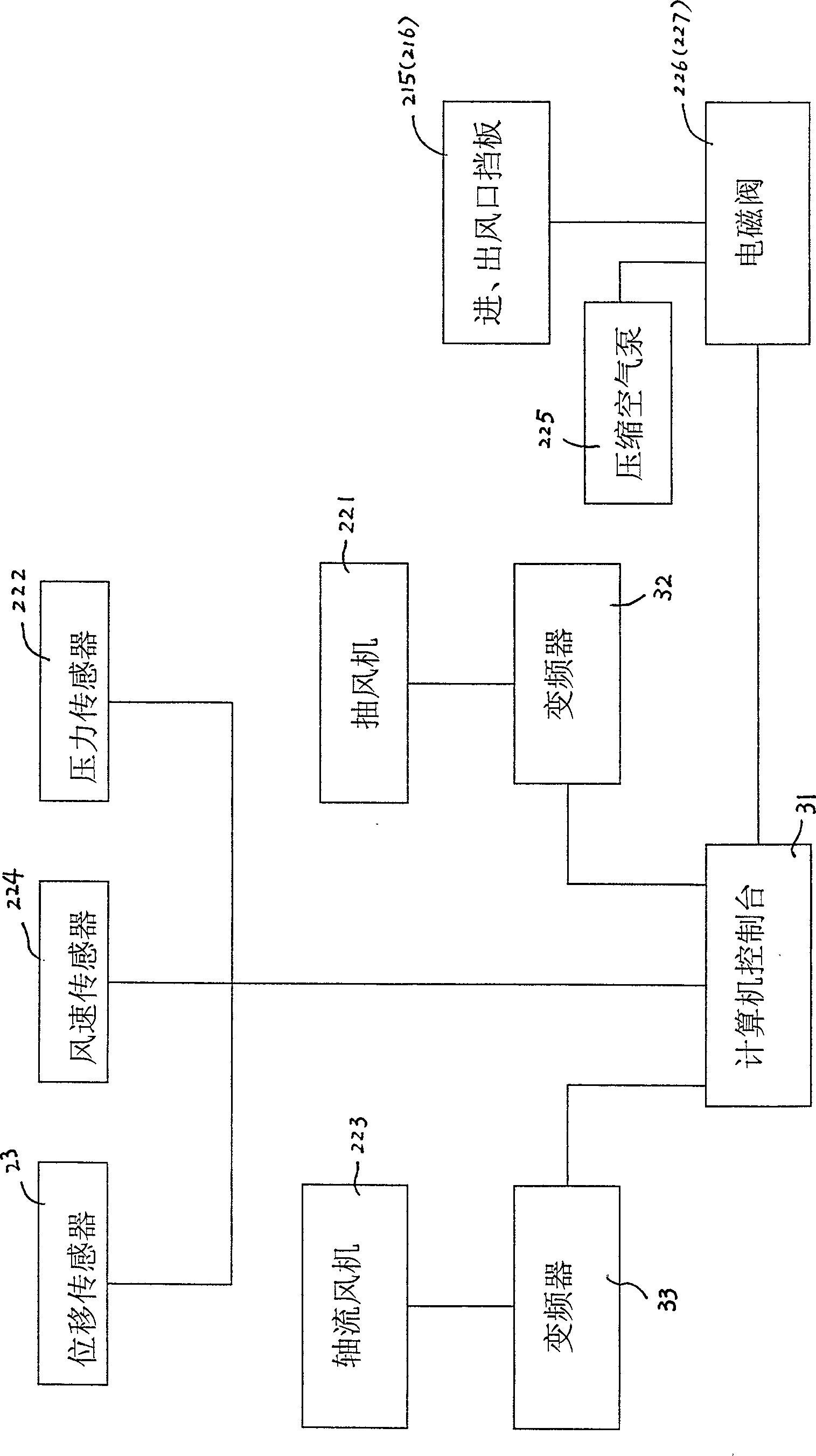

[0076] Install the sample template 18 on the keel 17, install the keel 17 on the mounting frame on the upper part of the testing equipment sample vehicle 1 according to the installation method provided by the manufacturer, and push the sample vehicle 1 so that the sample template 18 is located at the working position of the testing equipment. Fix the mounting frame on the upper part of the test port 211 of system 2; use the hand wheel 13 on the mounting frame to lower the sample plate 18, make the sample sample plate 18 stick to the elastic sealing strip 212 of the test port 211, and ensure that the system under test is not deformed ; Select three measuring points according to the actual shape of the suspended ceiling, and install a displacement sensor 23 on each...

Embodiment 2

[0084] Embodiment 2 is to carry out static load and dynamic load tests on a 600×800 square plate of a certain manufacturer. Concrete method step is with embodiment one, and its test result sees Figure 8 ~ Figure 11 .

[0085] Static load test results: It shows that the elastic deformation of the test sample 600×800 square plate is 3.5mm when the static wind pressure load is 160Pa (see Figure 8 ), ≤10mm; the plastic deformation when the static wind pressure load is 160Pa is 0.55mm (see Figure 9 ), ≤2mm, indicating that the product meets the static wind pressure load quality standard of the old similar products;

[0086] Dynamic load test results: the elastic deformation of the test sample 600×800 square plate is 6.8mm when the dynamic wind pressure load is 16m / s (see Figure 10), ≤10mm; the plastic deformation when the dynamic wind pressure load is 16m / s is 0.45mm (see Figure 11 ), ≤2mm, indicating that the product meets the new quality standard for static wind pressure...

Embodiment 3

[0087] The third embodiment is to carry out the dynamic load failure test on the 600×600 square plate of a certain manufacturer, the specific method is the same as the first embodiment, and the wind pressure is applied until the sample model is damaged.

[0088] The test results show that when the test sample 600×600 square plate is under the dynamic wind pressure load of 16m / s, the ceiling plate has already fallen off from the keel, indicating that the product does not meet the new quality of the static wind pressure load of similar products. Standard (coming soon).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com