Shockproof seat tube production process

A seat tube and process technology, which is applied to the production process of the shock absorber seat tube, can solve the problems of inability to effectively control the deflection of the seat cushion, and achieve the effects of good overall performance, easy assembly and control of the deflection of the seat cushion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

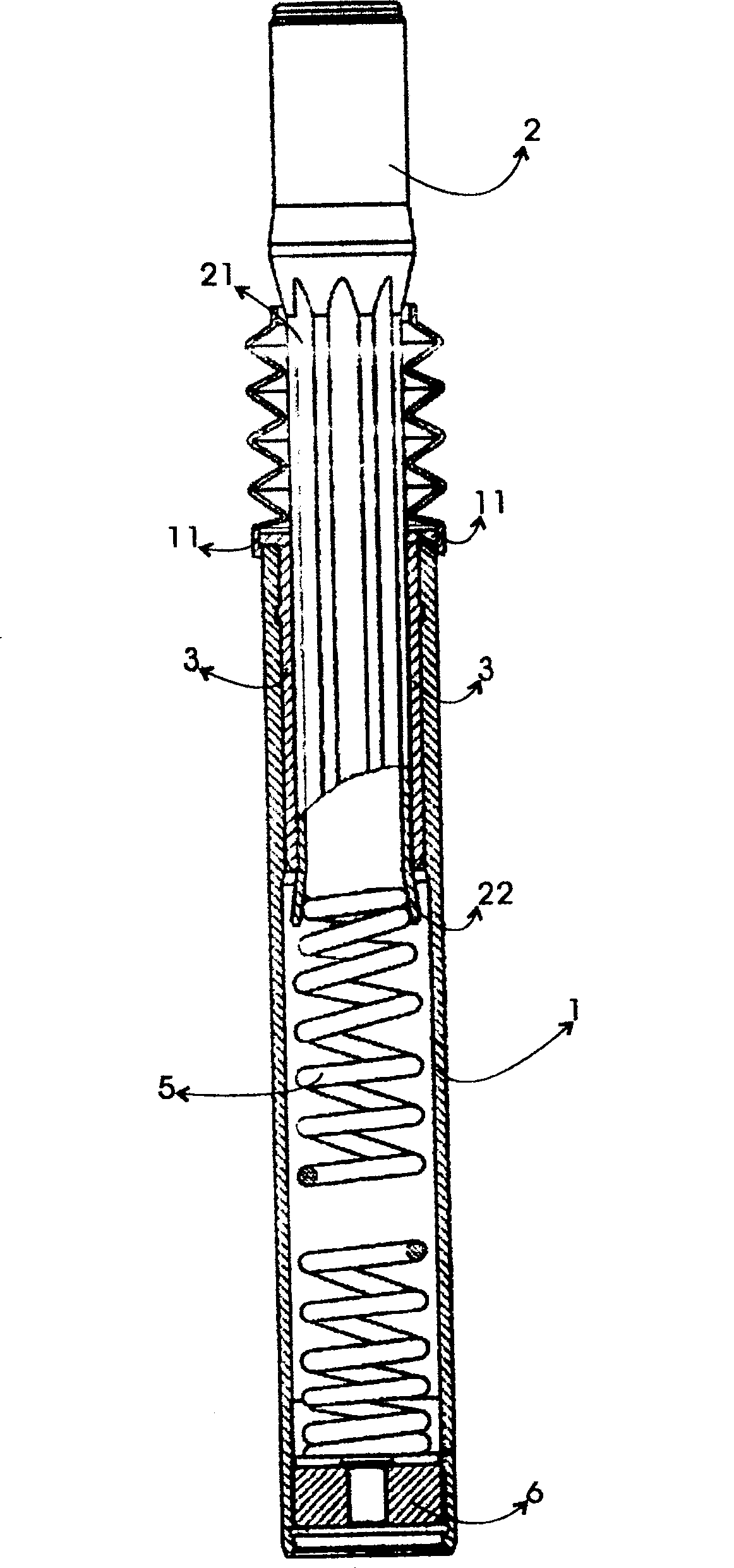

[0008] figure 1 It is a cross-sectional view of the assembly structure of the bicycle shock-absorbing seat tube of the present invention. Now, referring to the accompanying drawings, the production and assembly process of each component of the present invention is described in detail as follows.

[0009] First, the inner surface of the hollow outer tube 1 is machined into a polygonal shape and a positioning groove 11 is arranged on the top of the outer tube 1, and the finished outer tube 1 is processed by polishing, typing, anodizing, pad printing, etc. Then the outer surface 21 of the hollow inner tube 2 is processed into a polygonal shape corresponding to the inner surface of the outer tube 1, and then processed by chamfering, polishing, electroplating, etc., and the formed polygonal corner ends cannot be polished.

[0010] After making the polygonal inner tube 2 and outer tube 1 that match each other, assemble a plastic sliding sleeve 3 at one end of the outer tube 1, put t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com