Building structure system combined with steel beam and pre-tensioned prestressing superposed beam and construction method for building structure system

A construction method and technology of superimposed beams, applied in truss structures, joists, girders, etc., can solve the problems of high cost of joints, poor overall performance, and no reliability, and achieve lower floor heights, improved seismic performance, and enhanced The effect of connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

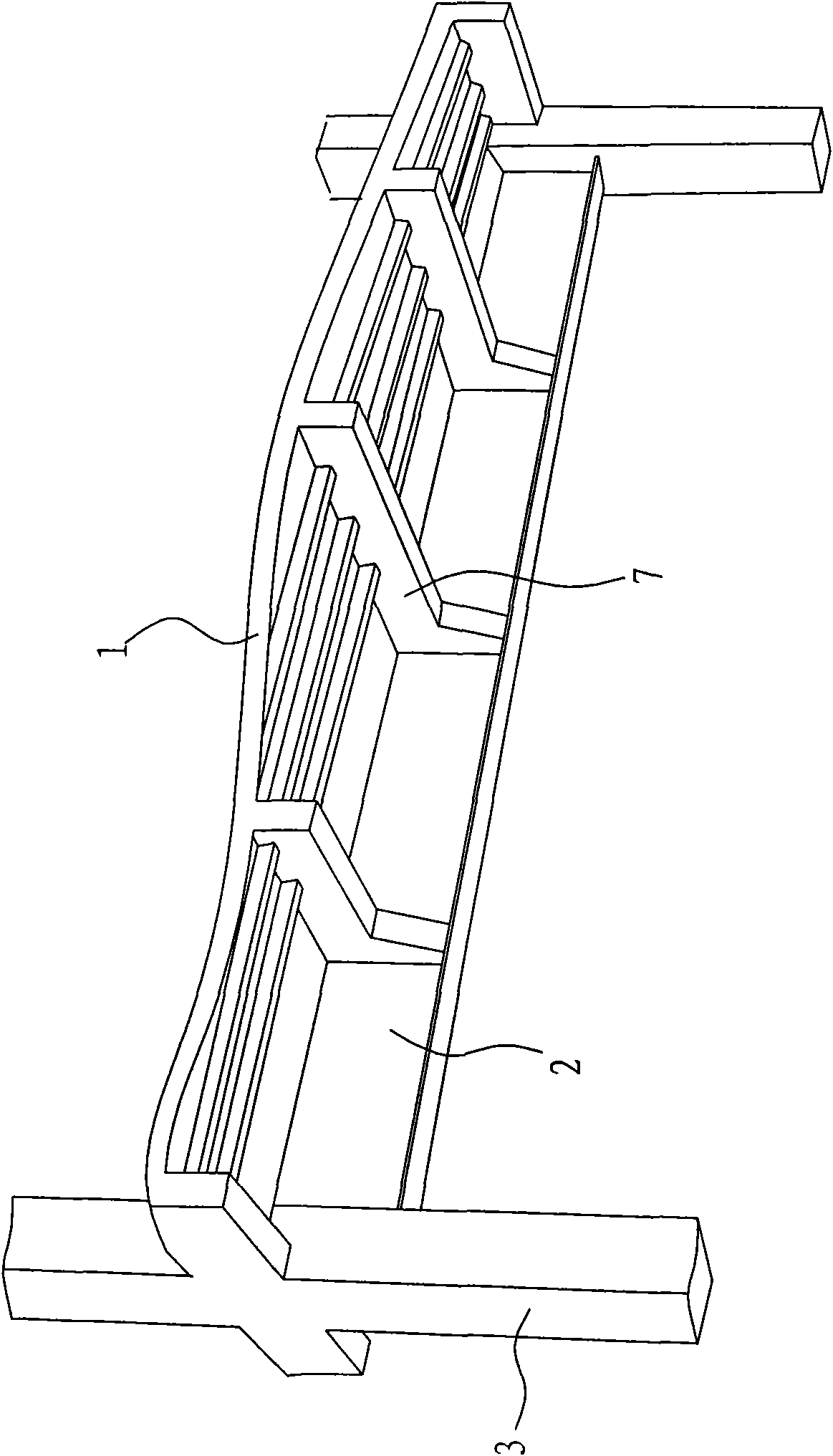

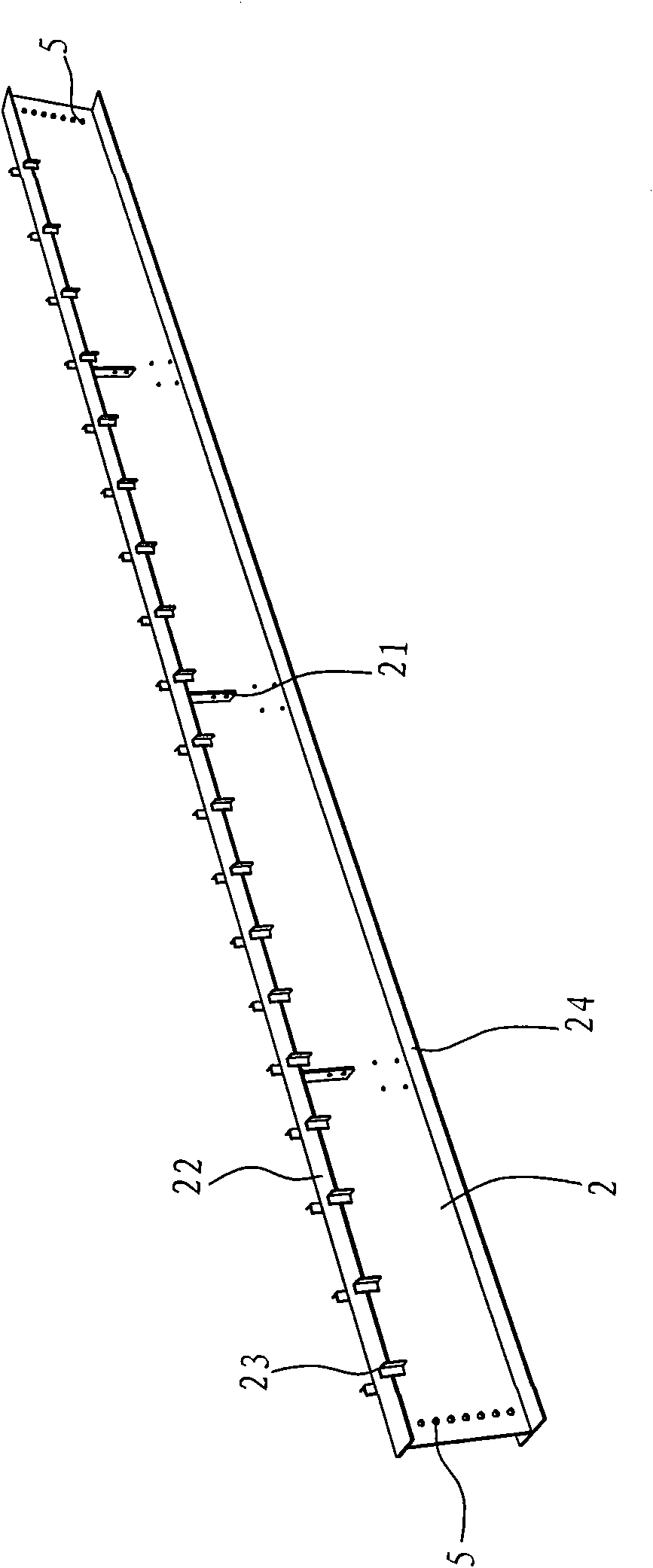

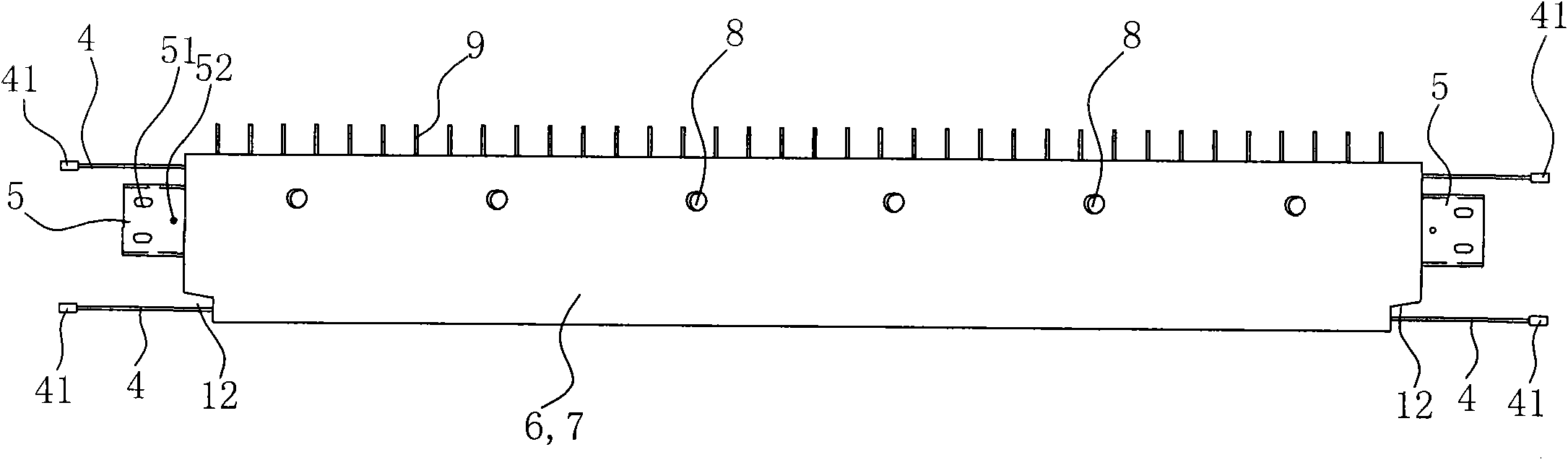

[0039] see figure 1 and Figure 6 , a building structure system in which a steel beam 2 and a pretensioned prestressed composite beam are combined in the present invention, including a floor slab 1, a pretensioned prestressed composite beam, and a large span supporting the composite beam H-shaped steel beam 2, steel reinforced concrete column 3 connected with the steel beam 2 and the composite beam, the composite beam includes a beam body and a prestressed steel strand 4 embedded in the beam body as a main reinforcement , the end of the beam body is provided with a section steel 5 suitable for connection with the external structure, the composite beam is divided into a main beam 6 and a secondary beam 7, and the main beam 6 is used to connect with the steel beam 2 For two adjacent steel reinforced concrete columns 3 in the perpendicular direction, the ends of the secondary beams 7 are fixed on the steel beams 2 .

[0040] The pre-tensioned prestressed composite beam includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com