Post-tensioning external prestressed steel beam and pre-tensioning prestressed superposed beam combined building structure system and construction technology thereof

A technology of external prestressing and post-tensioning method, applied in building construction, building material processing, construction, etc., can solve the complex construction process of post-tensioning method prestressed beam, poor lateral stability of the lower flange plate at the end, complete The cast-in-place process has long construction period and other problems, to achieve the effect of light weight, improved seismic performance and increased building space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

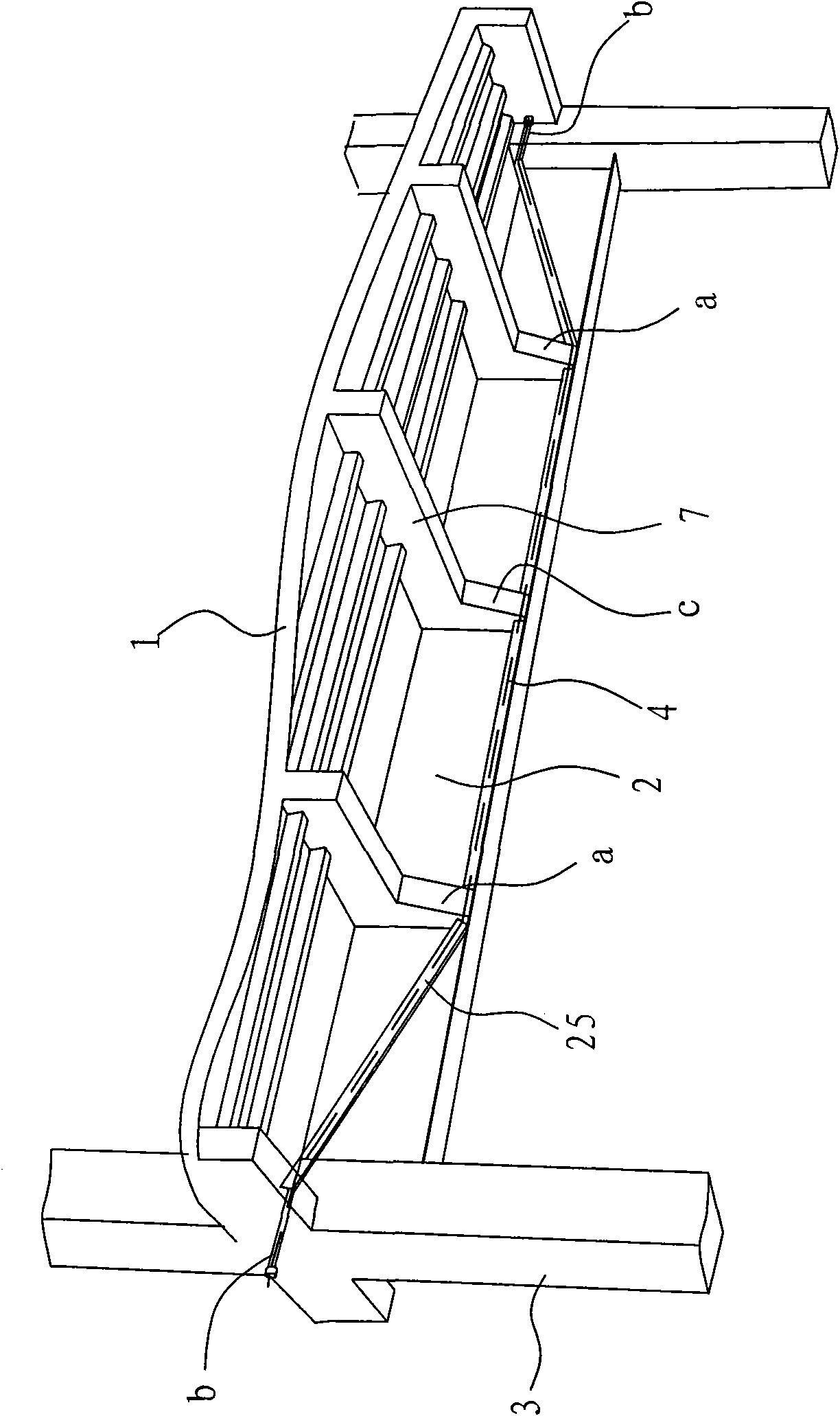

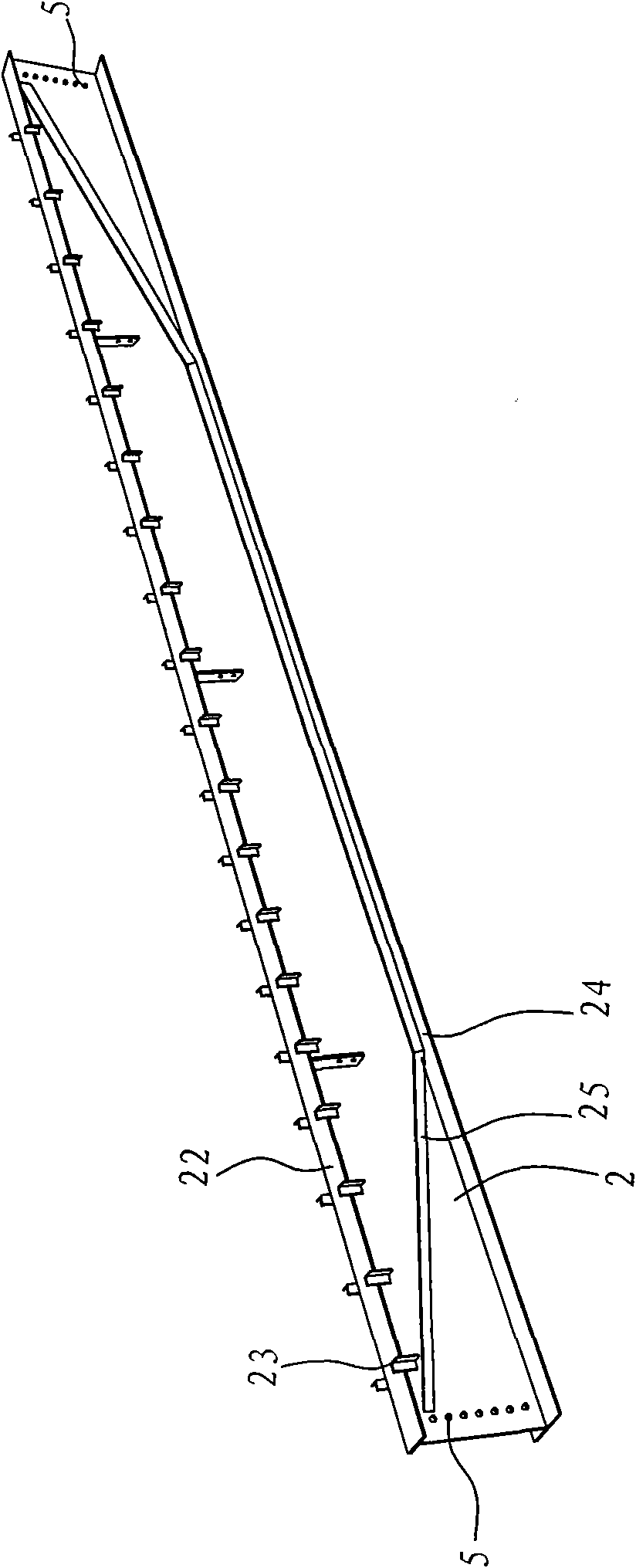

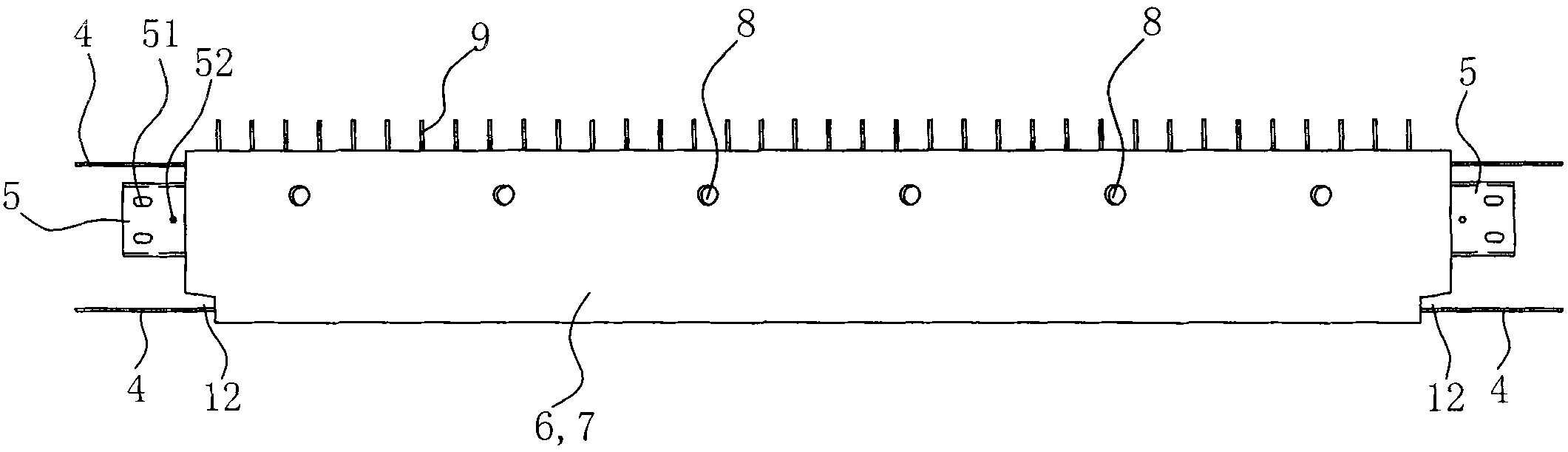

[0034] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0035] like Figure 1 to Figure 5 As shown, a building structure system combining post-tensioned externally prestressed steel beams and pre-tensioned prestressed composite beams provided by the present invention includes cast-in-place steel reinforced concrete columns 3, post-tensioned externally prestressed steel beams 2, The pretensioned prestressed composite beam and the cast-in-place floor 1, the steel beam 2 is an H steel beam, and the pretensioned prestressed composite beam includes a beam body and a prestressed steel strand embedded in the beam body as a main reinforcement Line 4, the end of the beam body is provided with section steel 5 suitable for connection with the external structure, the pretensioned prestressed composite beam is divided into a main beam 6 and a secondary beam 7, and the main beam 6 is used for Two adjacent steel-reinforced concrete colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com