Efficient energy-saving drying process and apparatus

A drying equipment and high-efficiency technology, applied in drying, dryer, lighting and heating equipment, etc., can solve the problem of reducing infrared radiation energy, and achieve the effect of no thermal inertia, shortened drying time, and advanced technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

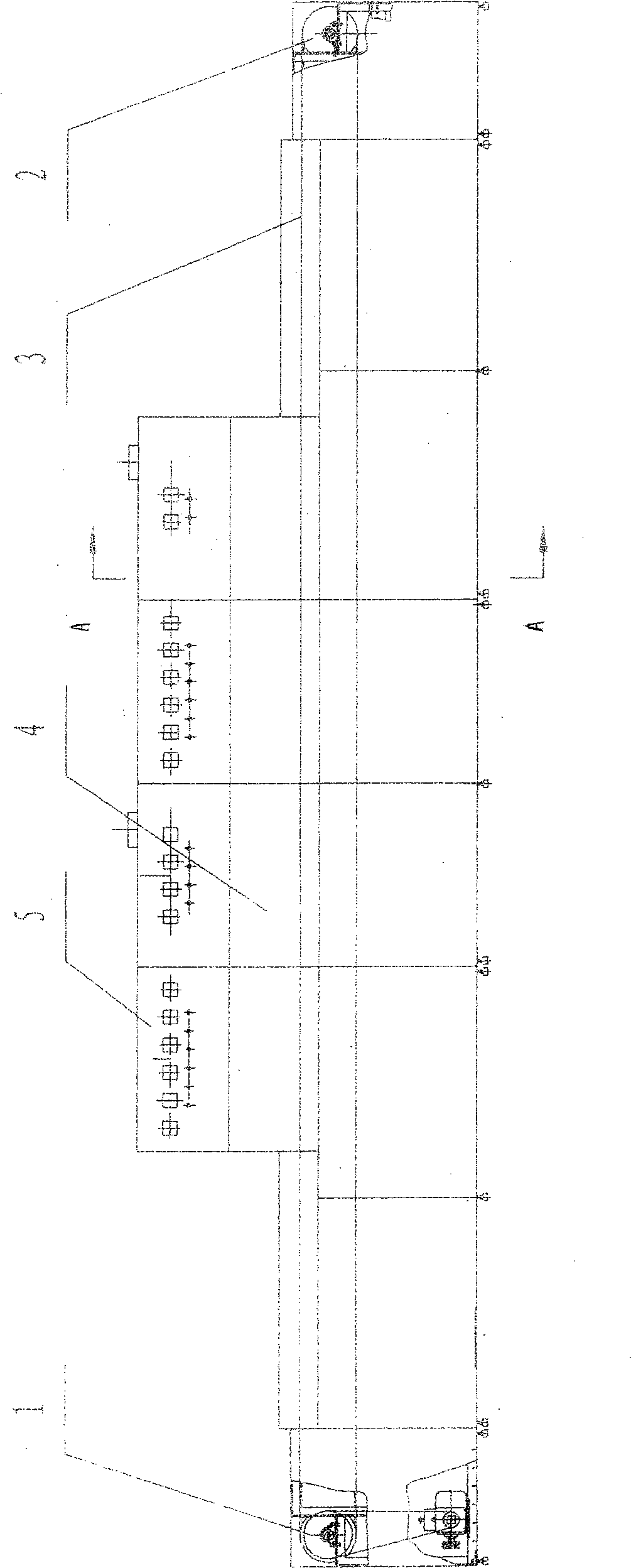

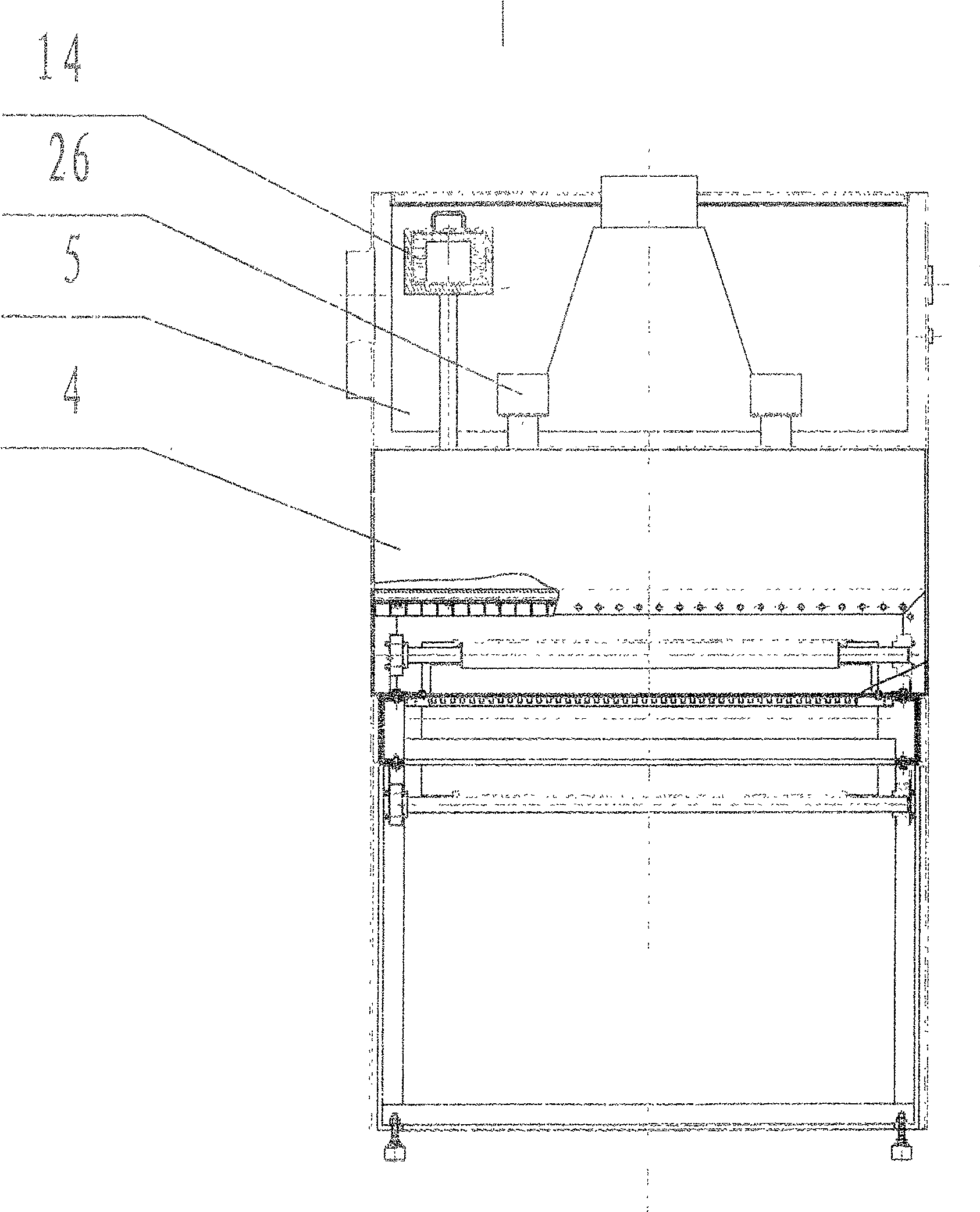

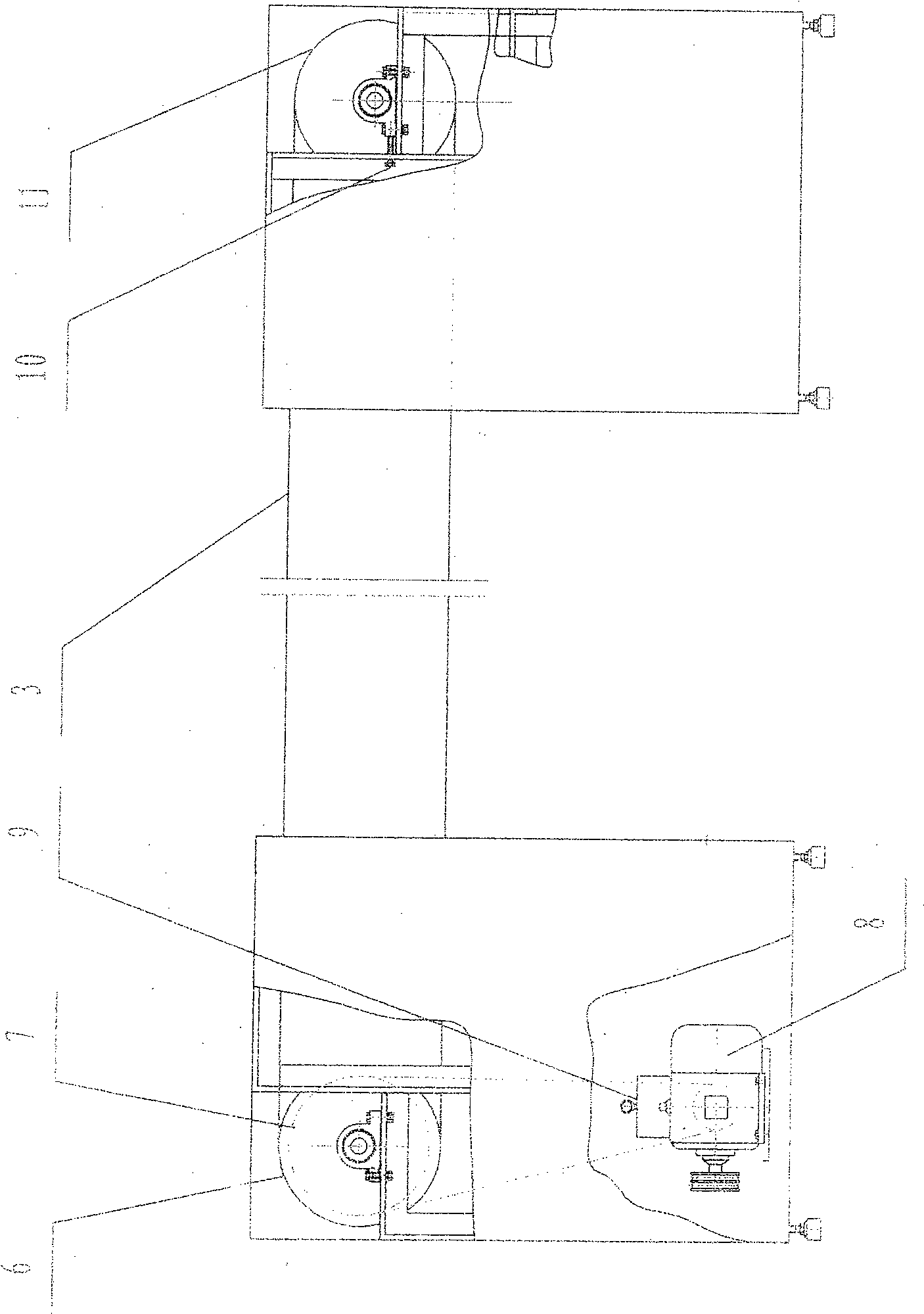

[0049] Example figure 1 As shown, the tunnel-type crawler microwave drying device is two large and small horizontal cuboids superimposed into a convex structure, which includes a main transmission mechanism 1, a passive transmission mechanism 2, a conveyor belt 3, a microwave cavity 4, and an electrical box. 5. The main transmission mechanism 1 is at one end below the convex structure, and the passive transmission mechanism 2 is at the other end. The main transmission mechanism 1 and the passive transmission mechanism 2 are connected by a conveyor belt 3, and the microwave cavity 4 is located at the main transmission mechanism 1 and the passive transmission mechanism. Above the mechanism 2, the microwave cavity 4 and the electrical box 5 are two independent cavities, the electrical box 5 is above the microwave cavity 4, and the oil transformer box is at the two corners on one side of the rectangular parallelepiped electrical box 5 place.

[0050] figure 1 The tunnel-type c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com