Apparatus for pouring magnesium-alloy quantitatively

A quantitative pouring, magnesium alloy technology, applied in metal processing equipment, equipment for supplying molten metal, casting equipment, etc., can solve the problems of discontinuous die casting production, clogging of the pouring pipe, and decreased quantitative accuracy, and achieves low quantitative accuracy. The effect of solving blockage and avoiding oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

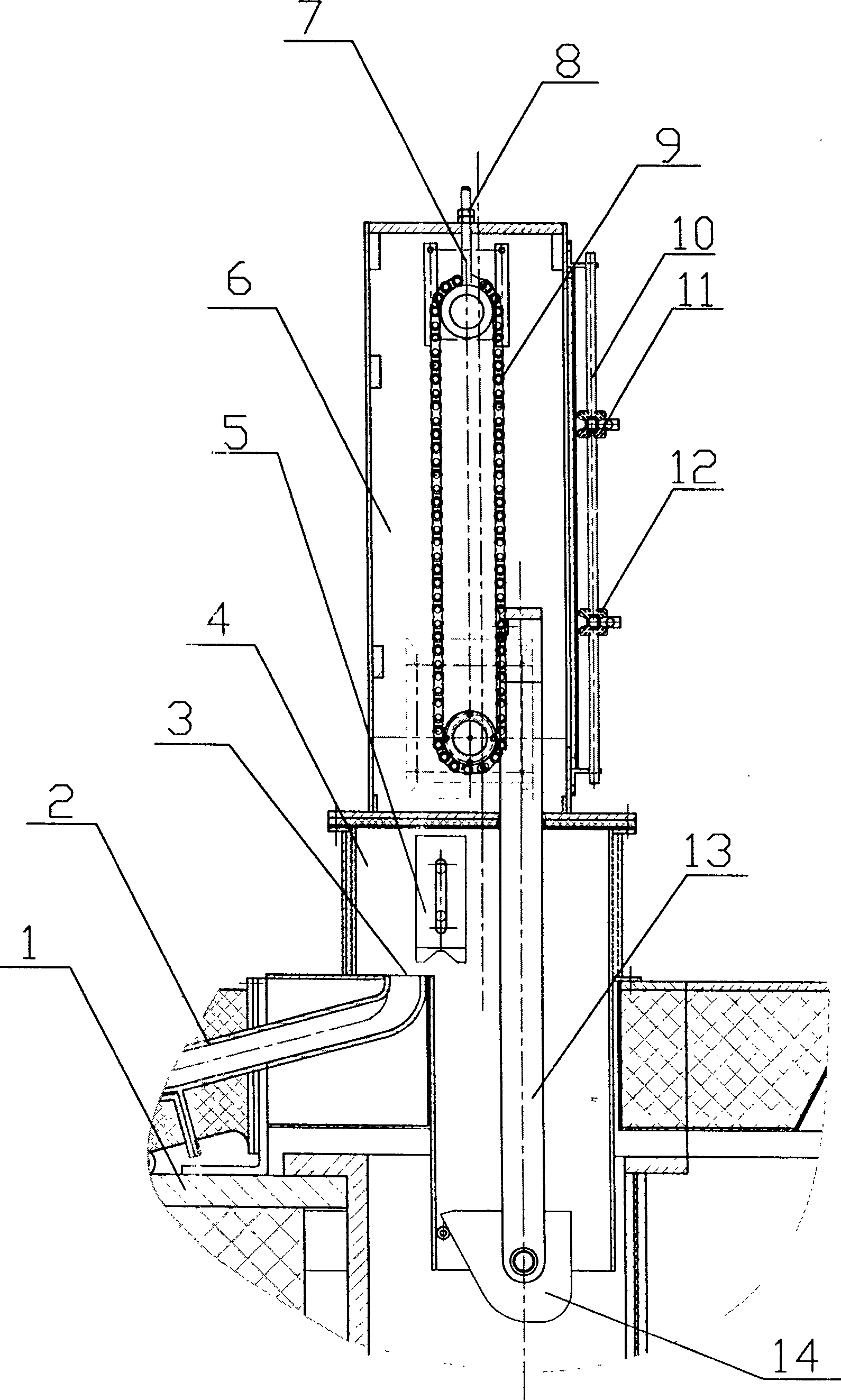

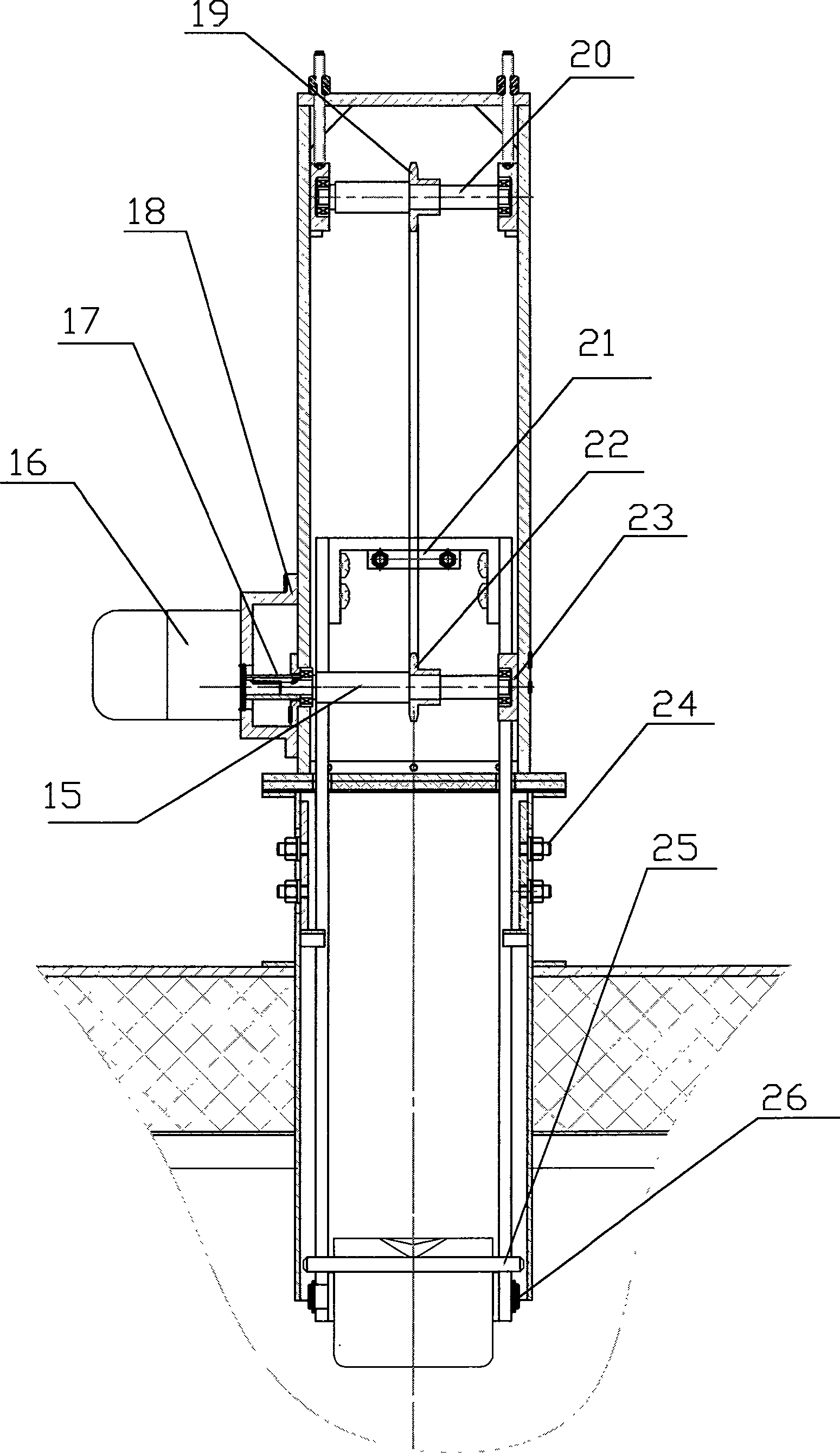

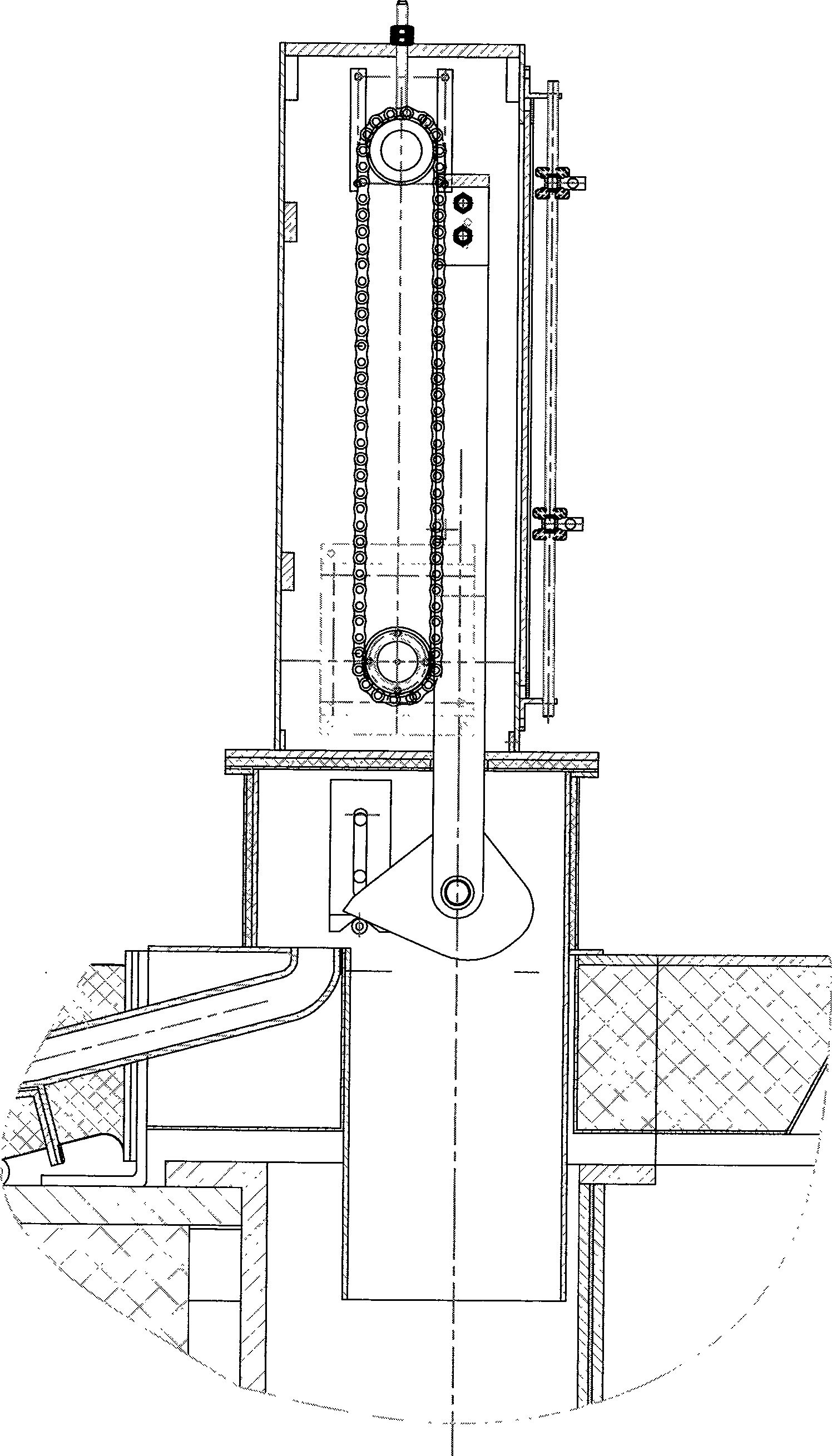

[0015] as attached figure 1 , 2 Shown is an embodiment of the present invention, and the present invention comprises a ladle channel 4 that one end is arranged in the body of furnace 1, the gantry 13 that is arranged in the ladle channel 4, is arranged at the lower end of the gantry 13 and is driven by a transmission device. The pouring ladle 14 moving up and down in the ladle channel 4 and the discharge port 3 arranged at the upper end of the ladle channel 4, the discharge port 3 and the discharge pipe 2 are connected, and the upper end of the discharge port 3 is inside the ladle channel 4 Quantitative clamping plate 5 is provided, is provided with pouring spoon retaining shaft 25 correspondingly on pouring spoon 14, adopts rotating shaft 26 to be connected between pouring spoon 14 and gantry 13, as attached image 3 As shown, the transmission device drives the watering ladle 14 to rise through the gantry 13, the quantitative clamping plate 5 blocks the blocking shaft 25 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com