Platinum/carbon catalyst and application thereof

A carbon catalyst, catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, organic chemistry and other directions, can solve the problems of low selectivity of aminophenol generation, and achieve low cost and high Active, highly selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

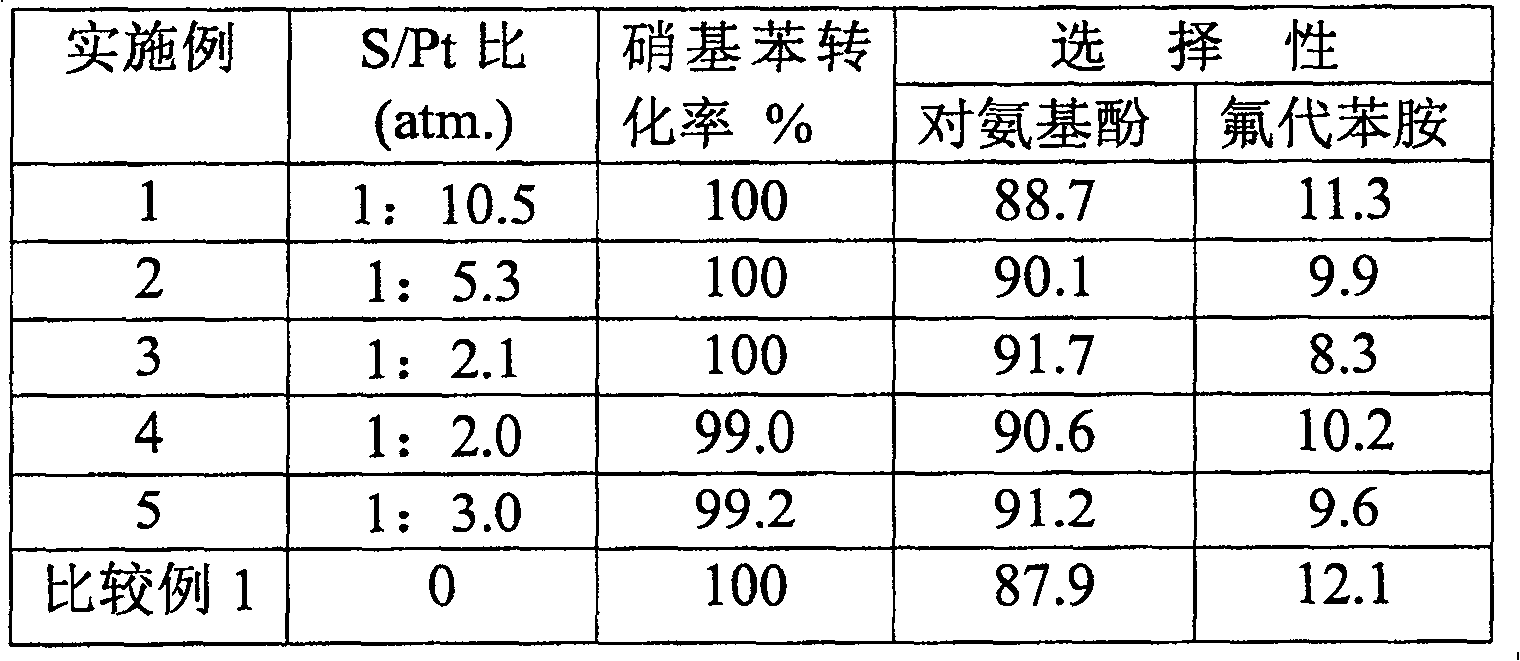

Embodiment 1

[0021] Put 1.5 g of activated carbon in 12 ml of 2N nitric acid and stir at 80°C for 1 hour, add 2.0 ml of platinum-containing 0.0148 g / ml solution, continue stirring for 2 hours, cool down to 40°C, add 20 µl of hydroxyethanethiol, continue Stir for 10 minutes, add 1.5 ml of 36% formaldehyde solution, stir for 0.5 hours, add dropwise 4 g equivalent / liter of sodium hydroxide aqueous solution, adjust the pH value of the solution to 8-9, and raise the temperature to 80 ° C to promote the reduction reaction. Add sodium hydroxide solution to keep the pH value in the range of 8-9 until complete reduction. The platinum / carbon catalyst was filtered out, washed with deionized water to remove chloride ions, and dried at 80° C. for 6 hours to obtain a platinum / carbon catalyst containing 2w% platinum and a sulfur / platinum atomic ratio of 1:10.

Embodiment 2

[0023] Put 1.5 g of activated carbon in 12 ml of 2N nitric acid and stir at 80°C for 1 hour, add 2.0 ml of platinum-containing 0.0148 g / ml solution, continue stirring for 2 hours, cool down to 40°C, add 1 ml of hydroxyethanethiol, and continue stirring After 10 minutes, add 1.5 ml of 36% formaldehyde solution, stir for 0.5 hours, add dropwise 4 g equivalent / liter of sodium hydroxide aqueous solution, adjust the pH value of the solution to 8-9, and raise the temperature to 80 ° C to promote the reduction reaction. Add sodium hydroxide solution to keep the pH value in the range of 8-9 until complete reduction. The platinum / carbon catalyst was filtered out, washed with deionized water to remove chloride ions, and dried at 80° C. for 6 hours to obtain a platinum / carbon catalyst containing 2w% platinum and a sulfur / platinum atomic ratio of about 1:5.3.

Embodiment 3

[0025] Put 1.5 g of activated carbon in 12 ml of 2N nitric acid and stir at 80°C for 1 hour, add 2.0 ml of platinum-containing 0.0148 g / ml solution, continue stirring for 2 hours, cool down to 40°C, add 100 µl of hydroxyethanethiol aqueous solution, Continue to stir for 10 minutes, add 1.5 milliliters of 36% formaldehyde solution, stir for 0.5 hours, add dropwise 4 g equivalent / liter of sodium hydroxide aqueous solution, adjust the pH value of the solution to 8-9, and heat up to 80 ° C to promote the reduction reaction. Add sodium hydroxide solution from time to time to keep the pH value in the range of 8-9 until complete reduction. The platinum / carbon catalyst was filtered out, washed with deionized water to remove chloride ions, and dried at 80° C. for 6 hours to obtain a platinum / carbon catalyst containing 2w% platinum and a sulfur / platinum atomic ratio of about 1:2.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap