Method for preparing platinum catalyst by electrodeposition

A platinum catalyst and electrodeposition technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low dispersion and coverage, and particle size reduction , low controllability and other issues, to achieve the effect of improving utilization and activity, simple application method and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

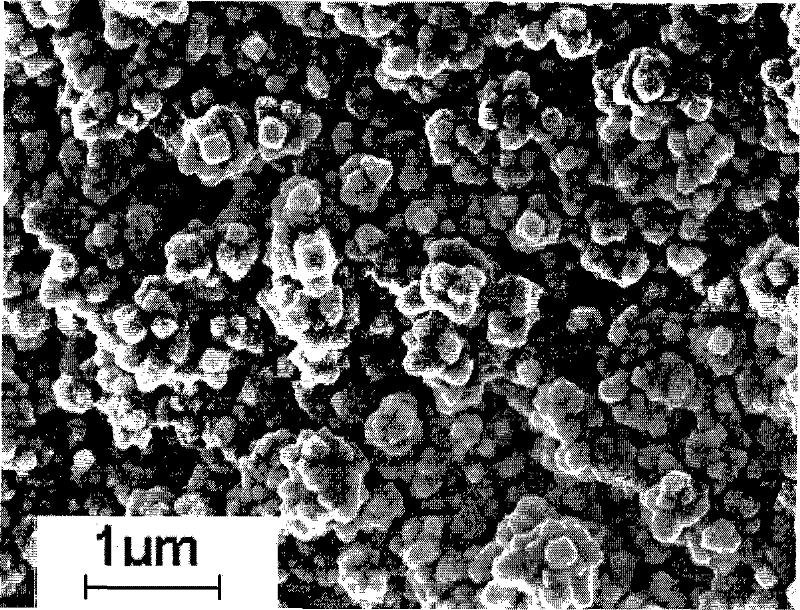

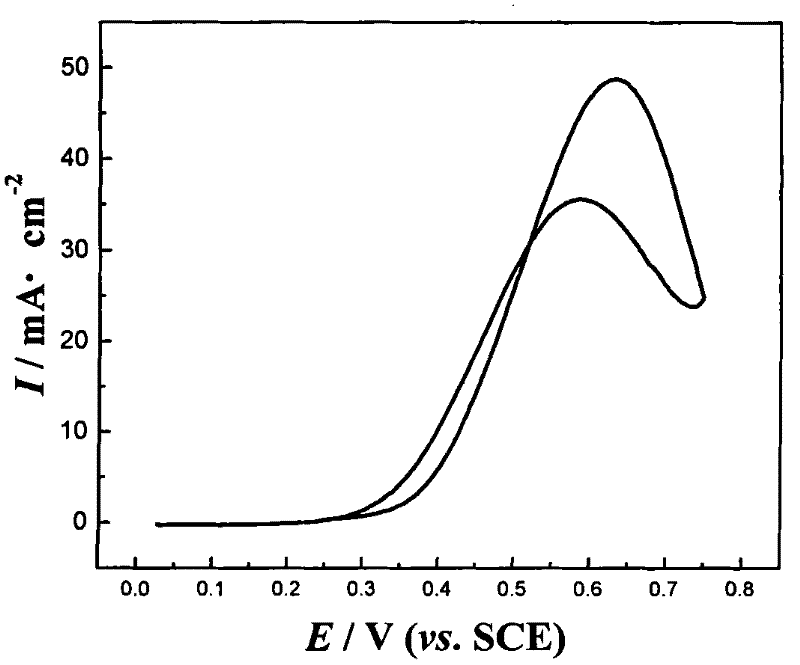

[0018] Weigh 50 mg of acidified Vulcan XC-72 into 10 mL of ethanol, add 100 μL of Solution (5wt.%, density 45mgNafion / mL) was ultrasonically dispersed for 60 minutes, mixed evenly to form a carbon slurry, The mass percentage of the solution and the ethanol suspension was 100:1; 75 μL was dropped onto the treated glassy carbon electrode (with an area of 0.28 cm 2 ) surface; after the ethanol evaporated, the electrode was vacuum-dried at 50°C for 7 hours to obtain the working electrode used in the electrodeposition process, the counter electrode was a platinum electrode, and the reference electrode was a saturated calomel electrode (SCE). The above potentials are all relative to SCE. The electrolyte is 0.5mol L -1 h 2 SO 4 +2.0mmol·L -1 h 2 PtCl 6 . Pulse electrodeposition is carried out in two stages for pulse electrodeposition of platinum, the I stage is at a peak current density of 12mA cm -2 After deposition for 120s, the peak current density in stage II is 8mA·...

Embodiment 2

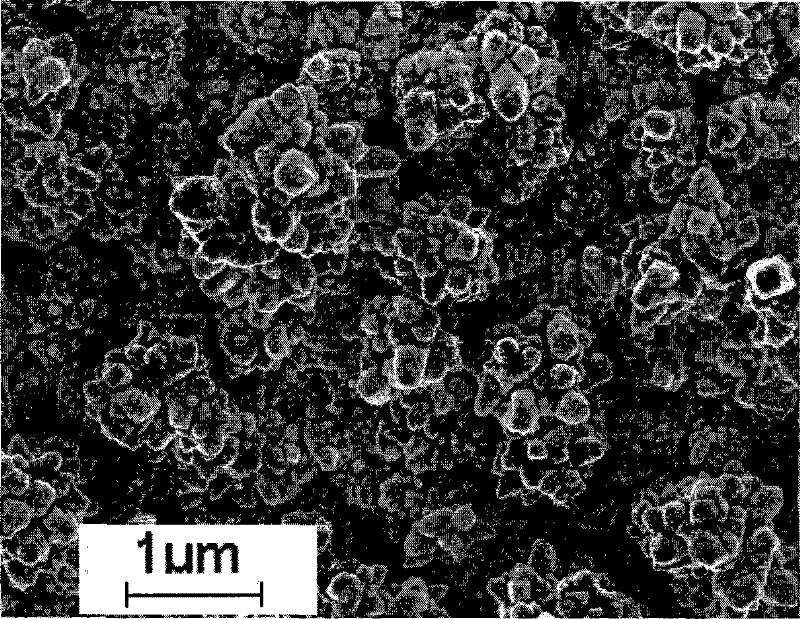

[0020] Weigh 40 mg of acidified Vulcan XC-72 into 5 mL of ethanol, add 200 μL of Solution (5wt.%, density 45mgNafion / mL) was ultrasonically dispersed for 40 minutes, mixed uniformly to form a carbon slurry, The mass percentage of the solution and the ethanol suspension is 100:4; take 75 μL and drop it on the treated graphite electrode (with an area of 0.5 cm 2 ) surface; after the ethanol evaporated, the electrode was vacuum-dried at 60°C for 5 hours to obtain the working electrode used in the electrodeposition process, the counter electrode was a platinum electrode, and the reference electrode was a saturated calomel electrode (SCE). The electrolyte is 0.5mol L -1 h 2 SO 4 +0.5mmol·L -1 h 2 PtCl 6 . Pulse electrodeposition is carried out in two stages for pulse electrodeposition of platinum, the I stage is at a peak current density of 36mA cm -2 Deposition for 60s, the peak current density of the second stage is 6mA·cm -2 , the total deposition charge is 1.2C cm ...

Embodiment 3

[0022] Weigh 50 mg of acidified Vulcan XC-72 into 10 mL of ethanol, add 200 μL of Solution (5wt.%, density 45mgNafion / mL) was ultrasonically dispersed for 30 minutes, mixed evenly to form a carbon slurry, The mass percentage of the solution and the ethanol suspension was 100:2; 100 μL was dropped on the surface of the treated graphite electrode; after the ethanol evaporated, the electrode was vacuum-dried at 60°C for 5 hours to obtain the working electrode used in the electrodeposition process , the counter electrode is a platinum electrode, and the reference electrode is a saturated calomel electrode (SCE). The electrolyte is 0.5mol L -1 h 2 SO4 +1.0mmol·L -1 h 2 PtCl 6 +10 -5 mmol·L -1 PEG (MW 400). Pulse electrodeposition is carried out in two stages for pulse electrodeposition of platinum, the I stage is at a peak current density of 24mA cm -2 Under deposition for 90s, the peak current density of stage II is 10mA·cm -2 , the total deposition charge is 12C cm -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com