Automatic blank-feeding system and bottle blower

A bottle blowing machine, automatic technology, applied in the field of automatic embryo loading system and bottle blowing machine, can solve the problems of high cost, high positioning accuracy, difficult adjustment of embryo loading, etc., and achieve the effect of simple embryo loading and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

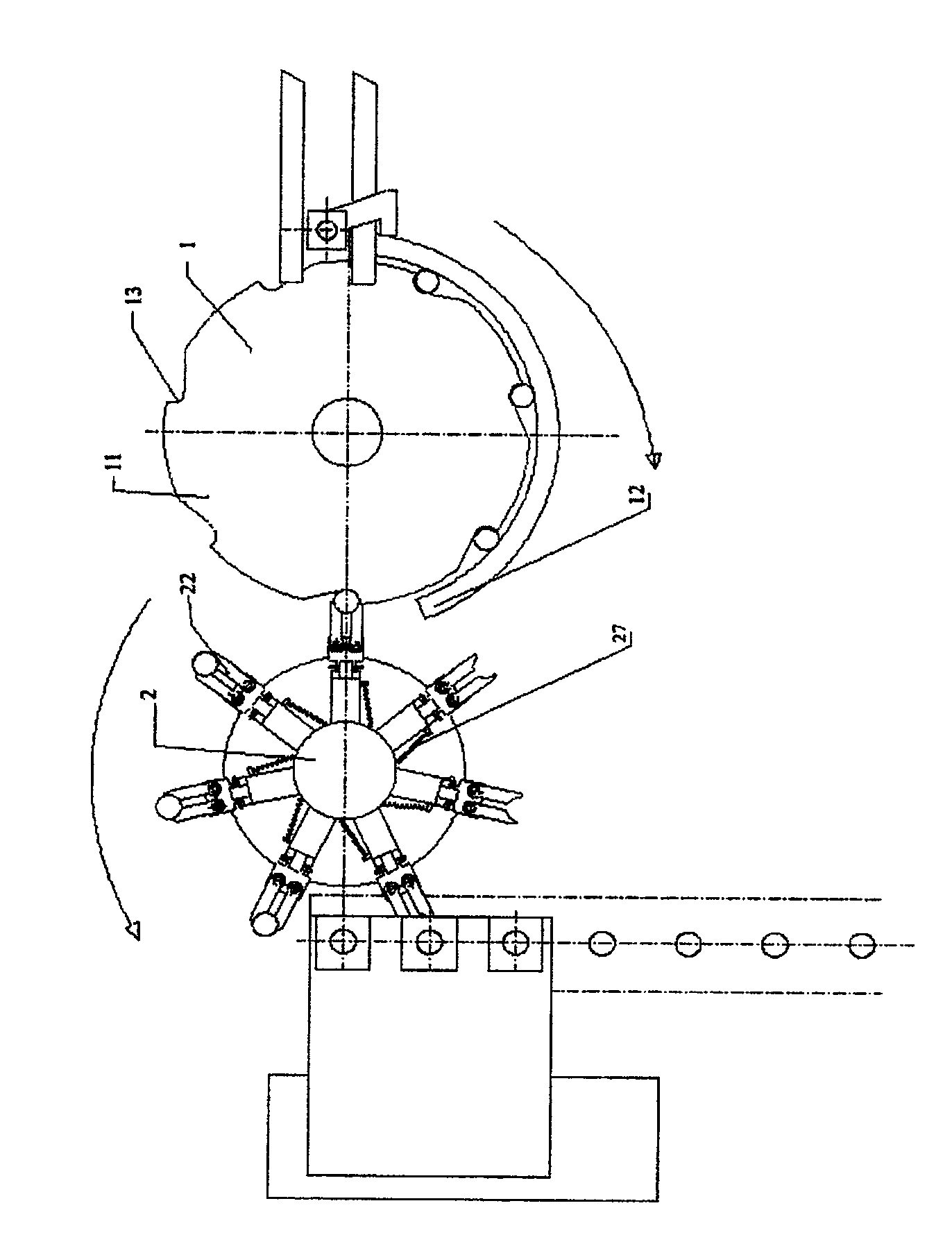

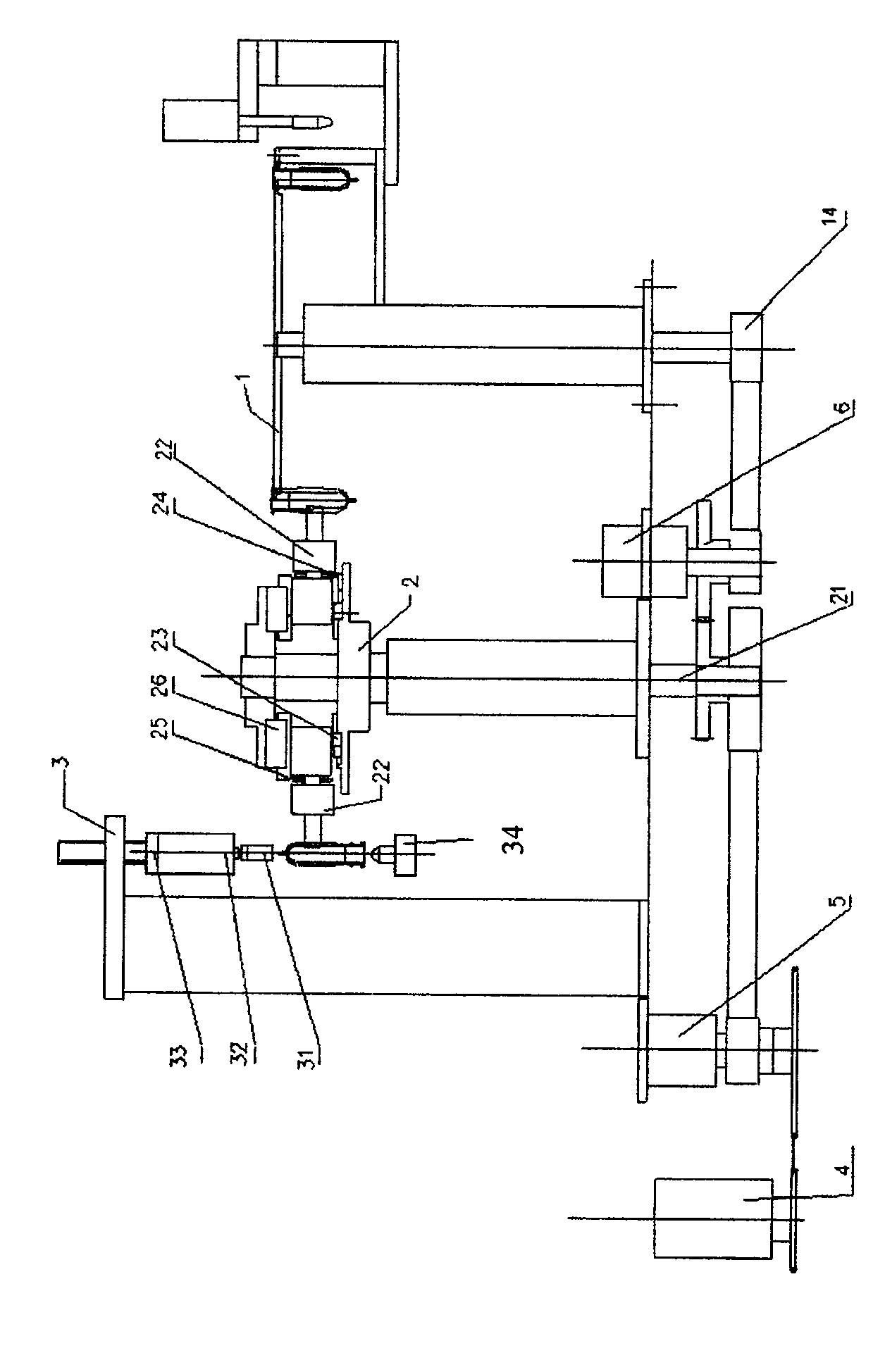

[0018] Such as figure 1 As shown, the automatic embryo feeding system of the bottle blowing machine according to the present invention includes a runner device 1 and a clamp device 2: the runner device 1 includes a runner 11 and an arc shield 12, and the periphery of the runner 11 is radially, etc. There are several notches 13 on the ground, and the arc guard plate 12 is arranged on the outer periphery of the runner 11 , which can clamp the preforms in the notches 13 movably, and transfer them to the clamping device 2 . The clamping device 2 is set at a different height position from the runner device 1 and partially overlaps each other, and has clamps 22 equal in number to the slots 13. Engage to clamp the preform conveyed by the notch 13. When the preform enters the notch 13 of the runner 11, it is clamped in the arc guard plate 12 and moves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com