Water-base type wax mould cleaning agent and preparation method thereof

A water-based, cleaning agent technology, used in detergent compositions, chemical instruments and methods, surface active detergent compositions, etc., can solve the problem of not completely solving wax mold cleaning agents, health hazards, poor use effects, etc. problems, to achieve the effects of obvious social and economic benefits, strong cutting oil, and reduced cleaning costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Water-based wax pattern cleaning agent, which includes nonylphenol polyoxyethylene ether, coconut oil fatty acid diethanolamide, trichloroethane, fatty acid polyoxyethylene ether sulfate, ethanol, purified water, the nonylphenol polyoxyethylene The consumption of vinyl ether is 11 parts by weight, the consumption of coconut oil fatty acid diethanolamide is 11.5 parts by weight, the consumption of trichloroethane is 2.5 parts by weight, the consumption of fatty acid polyoxyethylene ether sulfate is 10 parts by weight, and the consumption of ethanol is 1.5 parts by weight and 23 parts by weight of purified water.

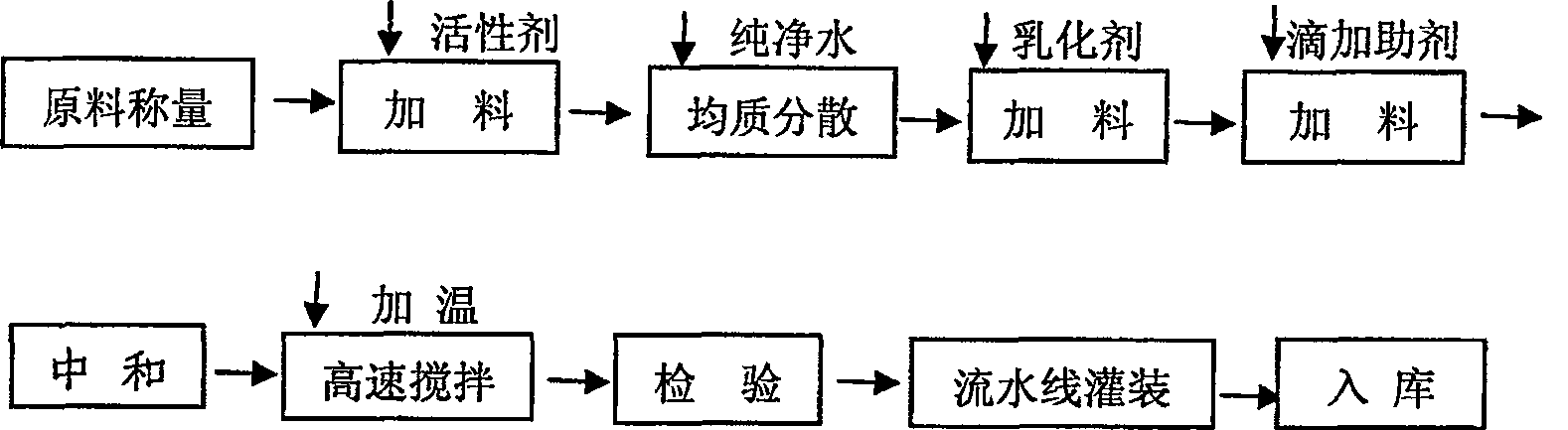

[0042] The preparation method is as follows:

[0043] 1. Weigh each raw material,

[0044] 2. Mix the active agent coconut oil fatty acid diethanolamide, trichloroethane and fatty acid polyoxyethylene ether sulfate evenly,

[0045] 3. Add solvent and pure water to disperse homogeneously,

[0046] 4. Add emulsifier nonylphenol polyoxyethylene ether,

[0047]...

Embodiment 2

[0050] Water-based wax pattern cleaning agent, which includes nonylphenol polyoxyethylene ether, coconut oil fatty acid diethanolamide, trichloroethane, fatty acid polyoxyethylene ether sulfate, ethanol, purified water, the nonylphenol polyoxyethylene The consumption of vinyl ether is 14 parts by weight, the consumption of coconut oil fatty acid diethanolamide is 9 parts by weight, the consumption of trichloroethane is 3 parts by weight, the consumption of fatty acid polyoxyethylene ether sulfate is 18 parts by weight, and the consumption of ethanol is 1 part by weight and 21 parts by weight of purified water.

[0051] In the preparation method, in step 6, at a temperature of 70 degrees, stirring at a speed of 600 rpm for 60 minutes. Others are with embodiment 1.

Embodiment 3

[0053]Water-based wax pattern cleaning agent, which includes nonylphenol polyoxyethylene ether, coconut oil fatty acid diethanolamide, trichloroethane, fatty acid polyoxyethylene ether sulfate, ethanol, purified water, the nonylphenol polyoxyethylene The consumption of vinyl ether is 13 parts by weight, the consumption of coconut oil fatty acid diethanolamide is 12 parts by weight, the consumption of trichloroethane is 4 parts by weight, the consumption of fatty acid polyoxyethylene ether sulfate is 15 parts by weight, and the consumption of ethanol is 2 parts by weight and 22 parts by weight of purified water.

[0054] In the preparation method, in step 6, the temperature is 80 degrees, the stirring speed is 600 rpm, and the time is 70 minutes. Others are with embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap