Safety display eccentric center trunnion

A trunnion and eccentric technology, applied in the direction of safety devices, load suspension components, cranes, etc., can solve problems such as trunnion easy decoupling accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

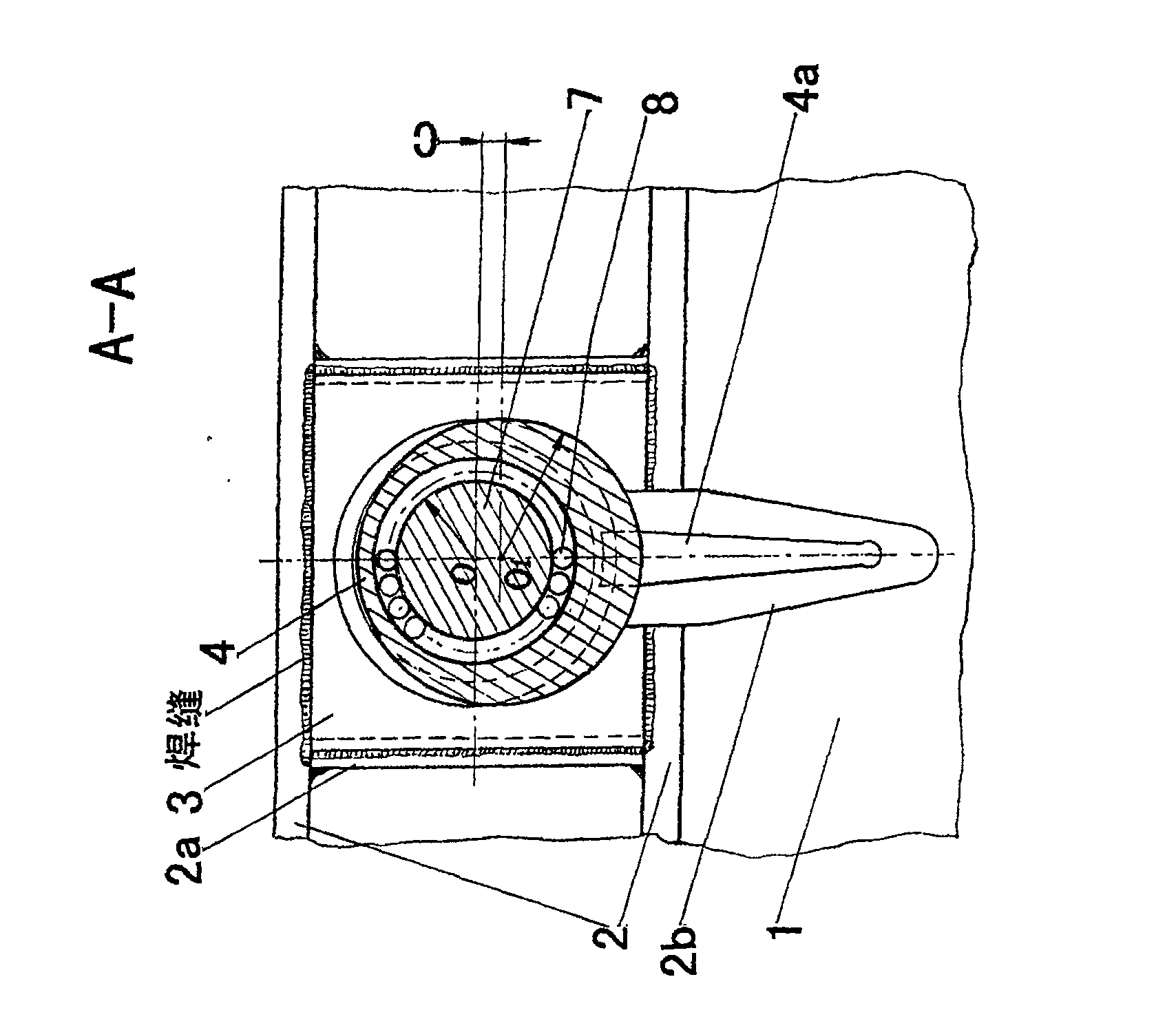

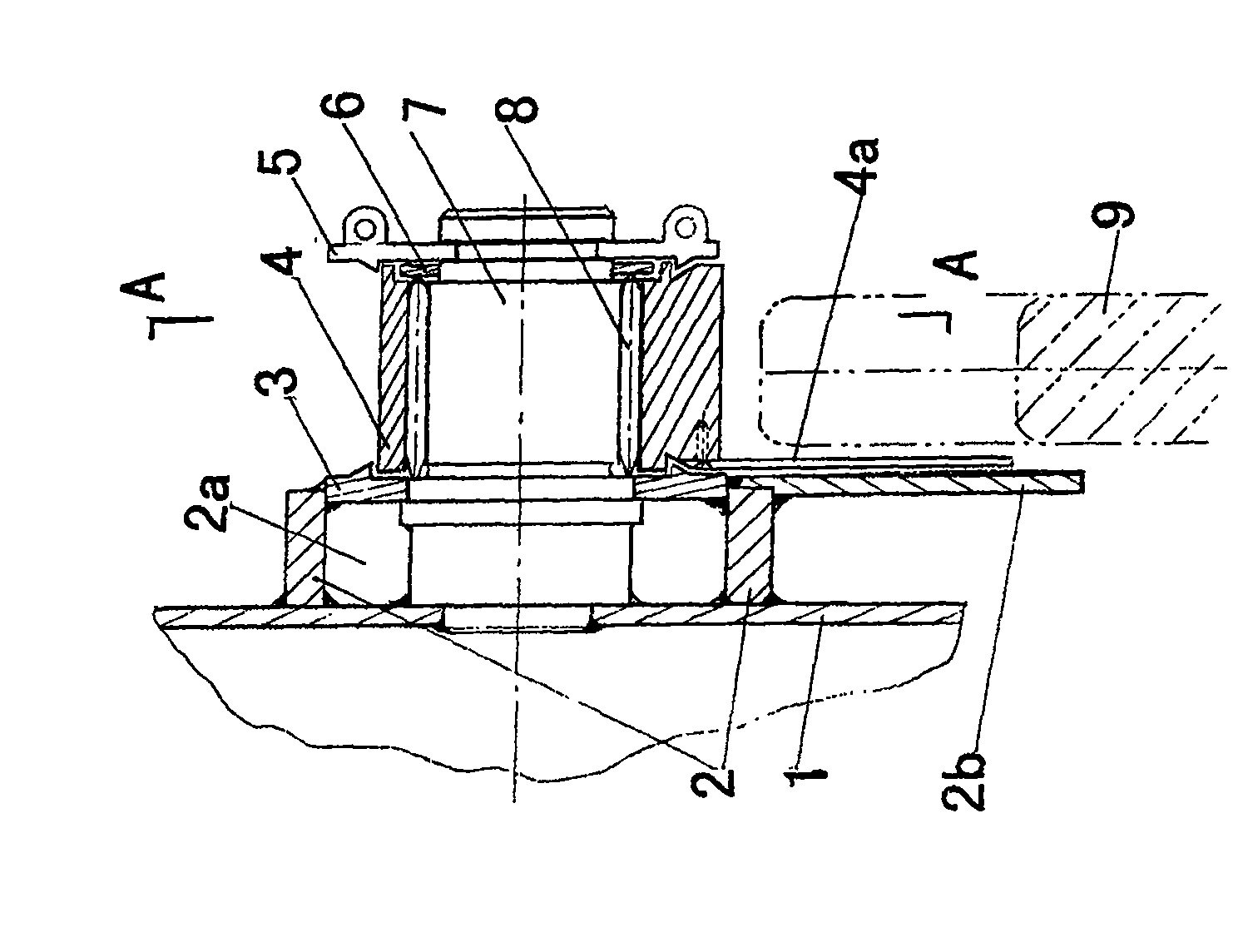

[0008] figure 1 , figure 2 1 is the outer wall of the ladle, 2 is the upper end of the ladle, two hoops up and down, 2a is the vertical welding plate on the left and right sides of the trunnion 7, and 3 is the trunnion square plate; figure 2 It shows that the trunnion 7 is fixedly welded by the ladle outer wall 1, the trunnion square plate 3, and the upper and lower hoops 2 to form a space structure, plus figure 1 The vertical welding plates 2a on the left and right sides form a cubic rigid body.

[0009] The overhanging cantilever shaft portion (after welding) of the trunnion 7 is induction hardened (the material is heat-resistant steel or high-speed steel). Rollers (rollers) 8 are evenly distributed outside the shaft column, and the eccentric cylinder 4 (hardened) is put on the outside, and there is a relatively obvious free gap after the fit (to prevent clamping after being heated), that is, the eccentric cylinder 4 is rolled by its own weight. The eccentric moment is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com