Intelligent lockstitch sewing machine

A lockstitch machine, intelligent technology, applied in sewing machine components, sewing machine protection devices, sewing equipment, etc., can solve problems such as difficulty in threading by operators, disconnection of sewing threads, etc., and achieve the effect of large operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

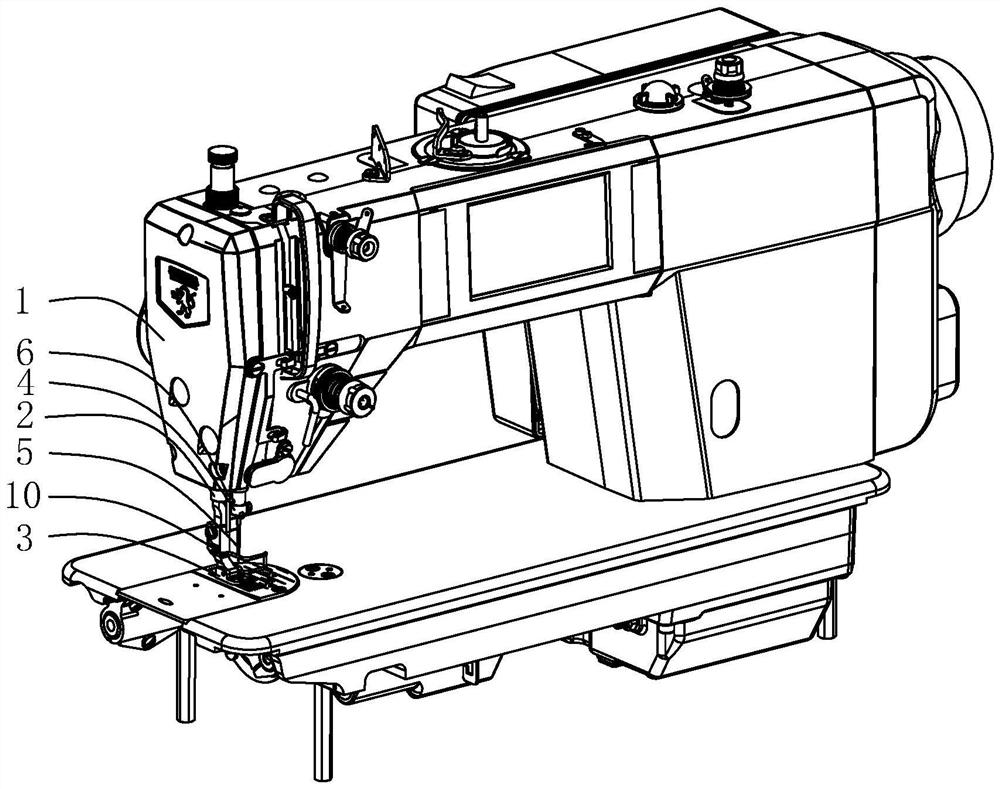

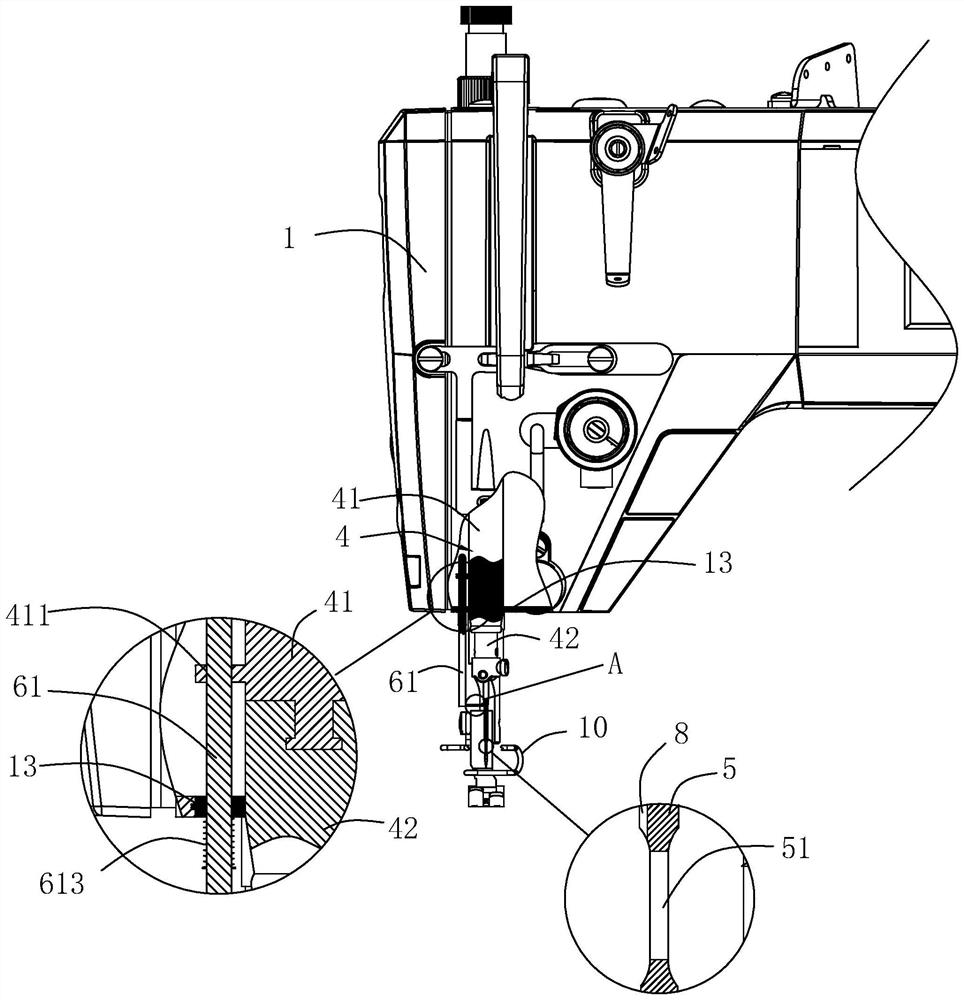

[0042] An intelligent lockstitch machine, see figure 1 as well as figure 2 , including the machine head 1, the machine head 1 is provided with a lifting pressure guide rod 2 and a sewing installation column 4, the end of the lifting pressure guide rod 2 is installed with a lifting presser foot 3, and the sewing installation column 4 is installed with a sewing needle 5. The sewing needle 5 is provided with a threading hole 51 . The lifting and pressing guide rod 2, the sewing installation column 4 and the sewing needle 5 are all vertically arranged.

[0043] see figure 1 as well as figure 2, a protective cover 10 is installed on the lifting and pressing guide rod 2 , and the protective cover 10 surrounds the peripheral position of the lifting and pressing foot 3 .

[0044] see Figure 4 , a rotating member 11 is rotatably connected to the lifting and pressing guide rod 2, the rotation axis of the rotating member 11 is arranged horizontally, and the protective sleeve 10 i...

Embodiment 2

[0060] Embodiment 2: a kind of use method of intelligent lockstitch sewing machine as in Embodiment 1:

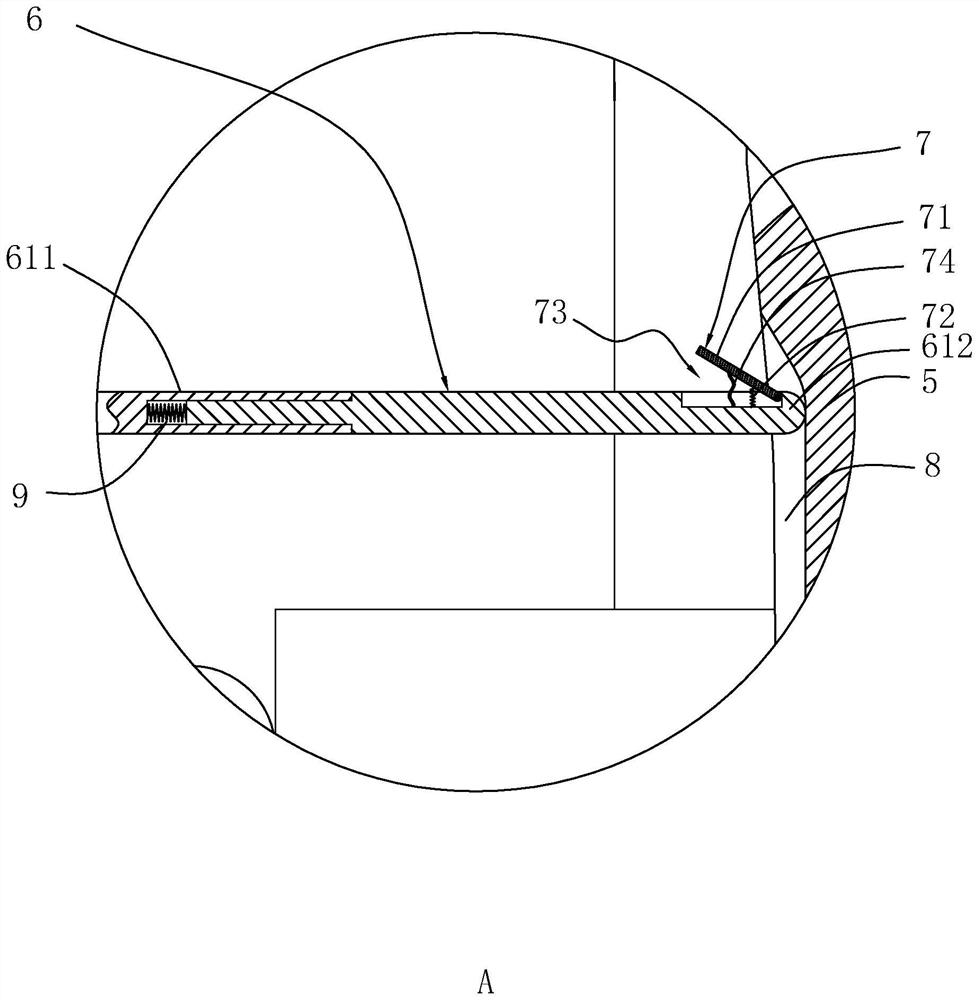

[0061] Step 1: Pull down the threading rod 61, the thread hooking end 612 moves down along the sliding groove 8, the threading rod 61 passes through the threading hole 51, and the thread hooking part 7 extends into the outside of the other side of the threading hole 51, The hook-line spring 72 supports the hook-line swing rod 71 upwards and forms the hook-line angle 73, and the threading rod 61 comes out from the limiting hole 411;

[0062] Step 2: According to the actual operation requirements, the threading rod 61 and the lower column 42 are rotated, and the orientation of the hooking part 7 can be adaptively changed. At the same time, the lower column 42 drives the primary transmission gear 121 and the secondary transmission gear 122 in turn. When rotating, the secondary transmission gear 122 drives the driving rack 123 to move downward, the driving rack 123 drives the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com