Nail box of nailing machine

A technology for nailing machines and nail magazines, applied in nailing tools, manufacturing tools, etc., which can solve the problems of increased weight, cost, and overall weight of nail magazines, and achieves the effects of cost suppression, less damage, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

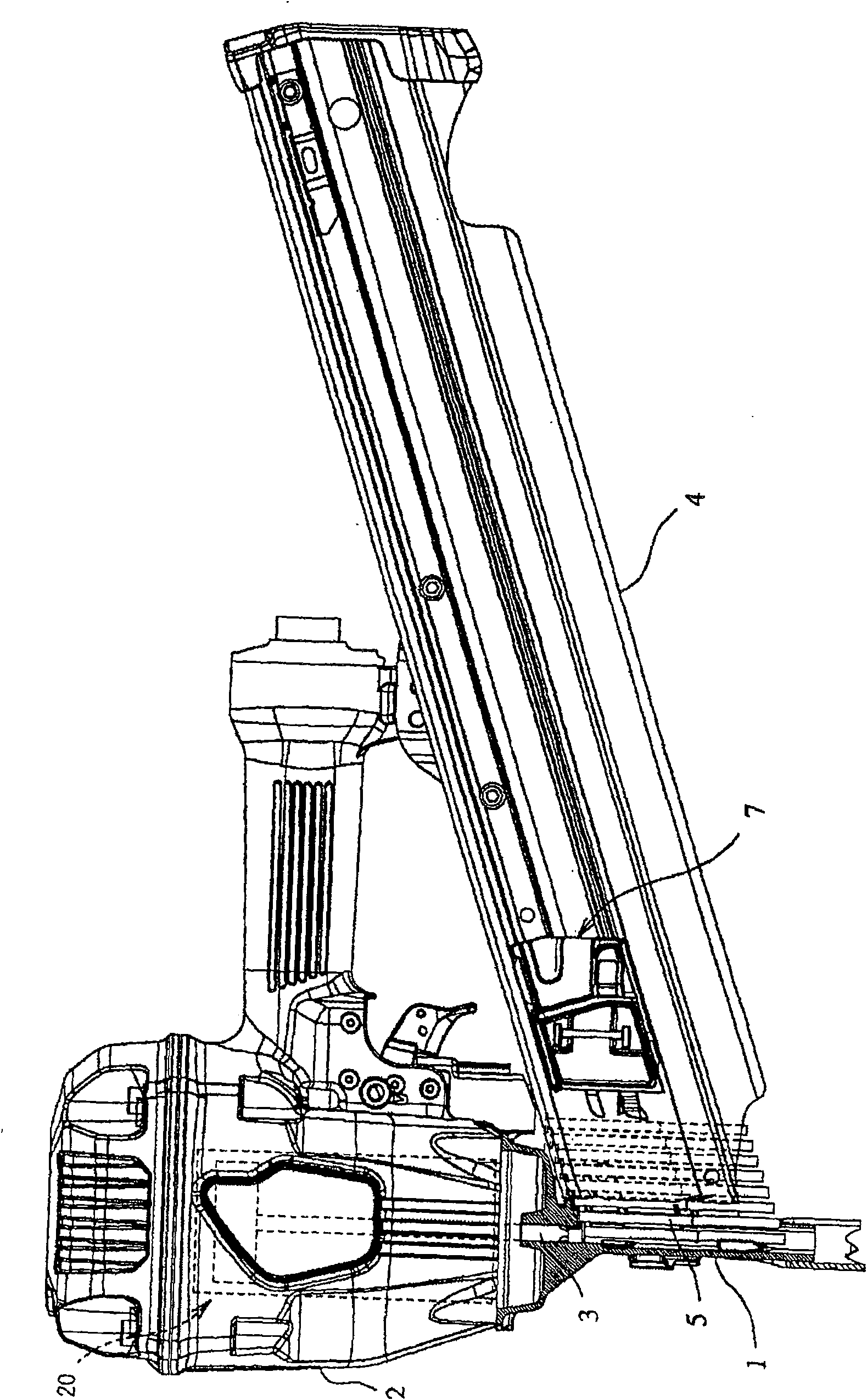

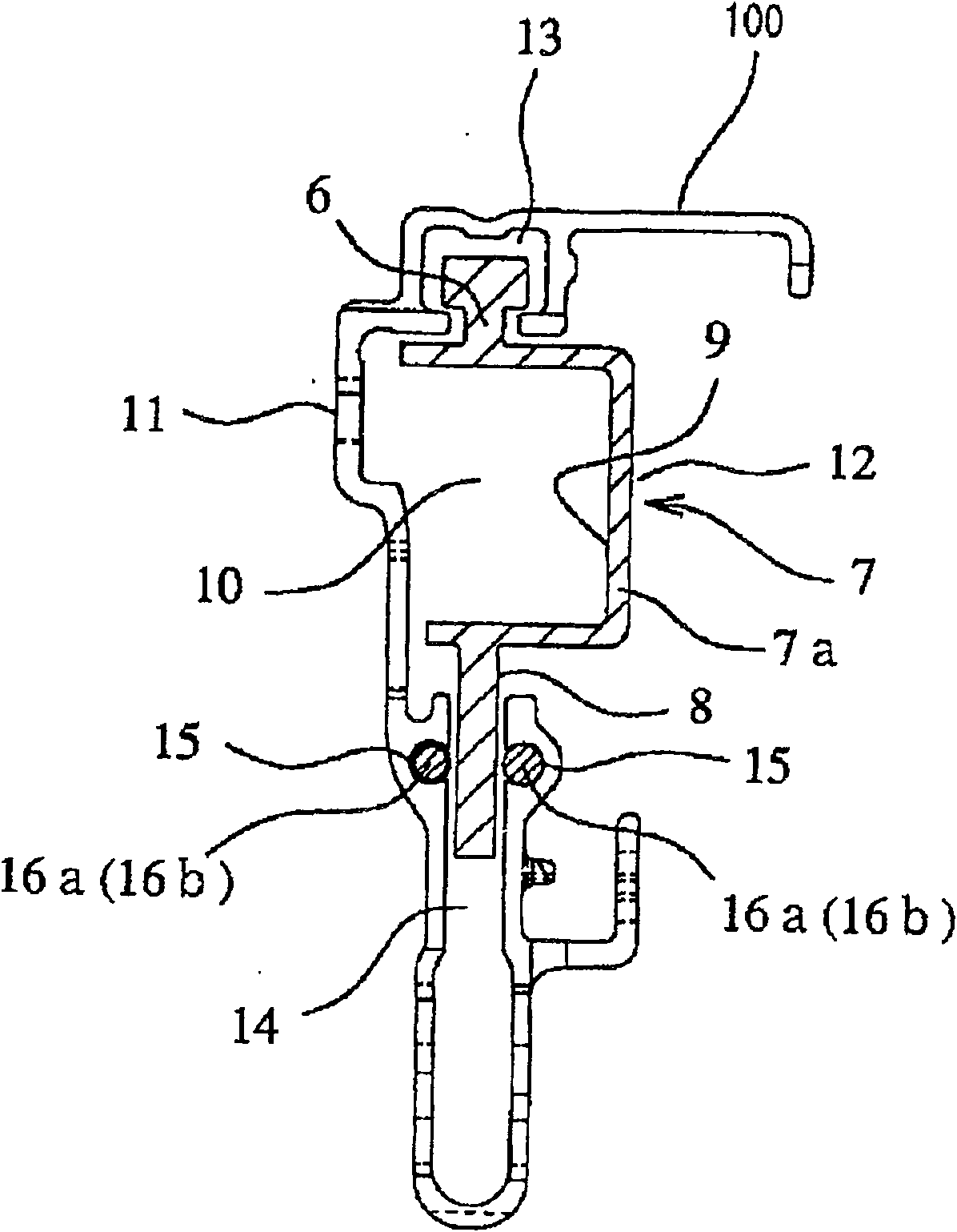

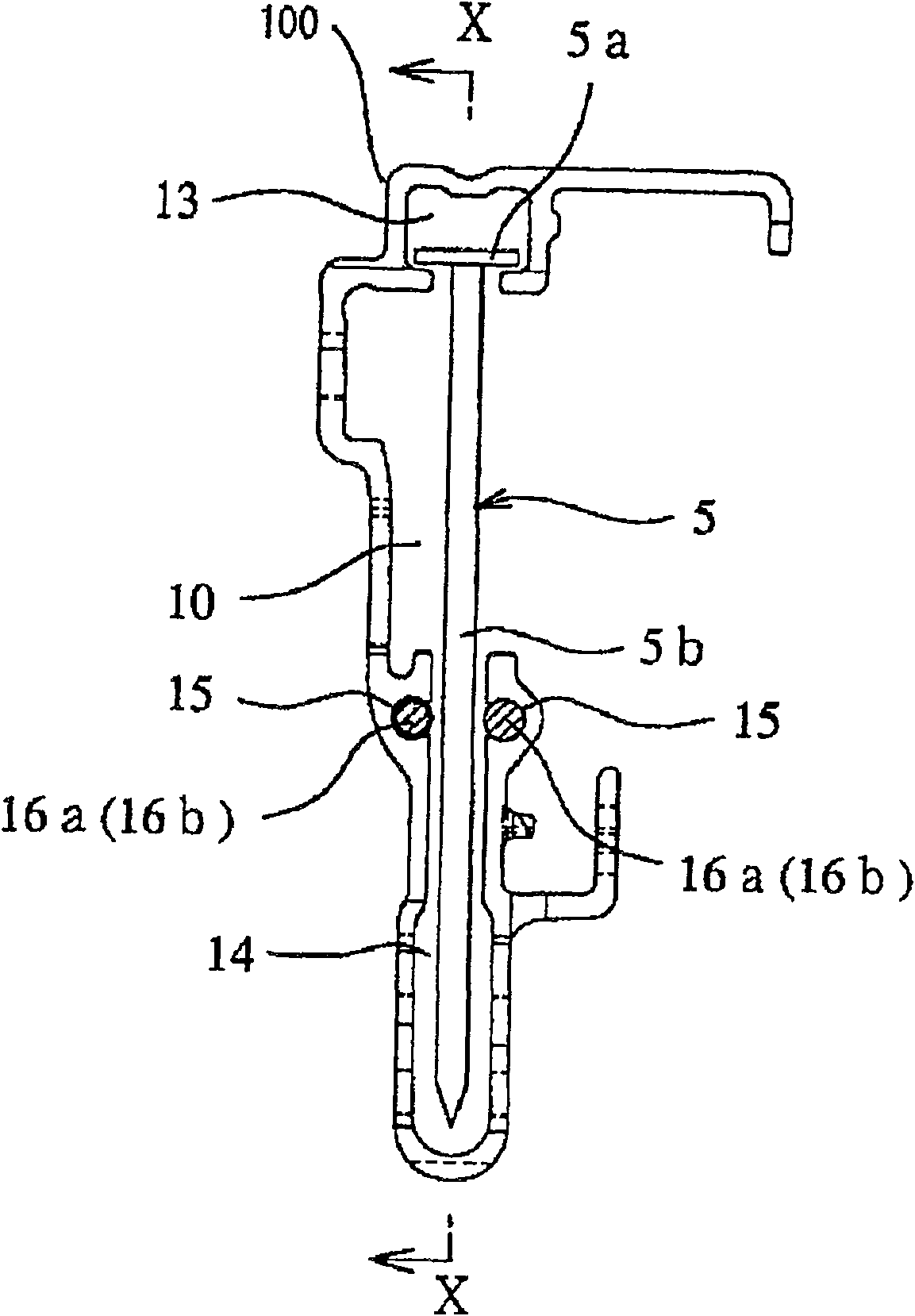

[0030] Hereinafter, typical embodiments of the present invention will be described with reference to the drawings.

[0031] exist figure 1 Among them, the symbol 1 represents the head of the nailing machine. The machine head 1 is a tubular part extending below the nailing machine main body 2, which guides the sliding of the driving device 3 driven by the striking mechanism 20 arranged on the nailing machine main body 2, and to the nail box 4. The front end is opened to accommodate the head nails of the connecting nails 5 loaded in the nail case 4, and guide the head nails struck by the driver 3 to the driving direction.

[0032] The connecting nail 5 is formed by connecting a plurality of iron nails straightly in a rod shape through a connecting piece, and the heads of each nail are connected in a stacked state. The connector is made of materials such as synthetic resin and paper. The connecting nails 5 loaded in the nail magazine 4 are in a slightly inclined state with res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com