Retainer positioning structure for linear sliding rail

A linear slide rail and positioning structure technology, applied in the direction of linear motion bearings, bearings, shafts and bearings, etc., can solve the problems of easy deformation, difficult shrinkage and deformation of the retainer, and inability to play the guiding ball 21, etc., so as to achieve easy assembly and disassembly , the effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make your examiners and people who are accustomed to this technology have a further understanding of the present invention, a preferred embodiment is given hereafter, and the details are as follows: (but, this embodiment is only for illustration, and the future development of the present invention Implementation is not limited to this, and all improvements and implementations based on the technical features of the present invention are bound by the present invention).

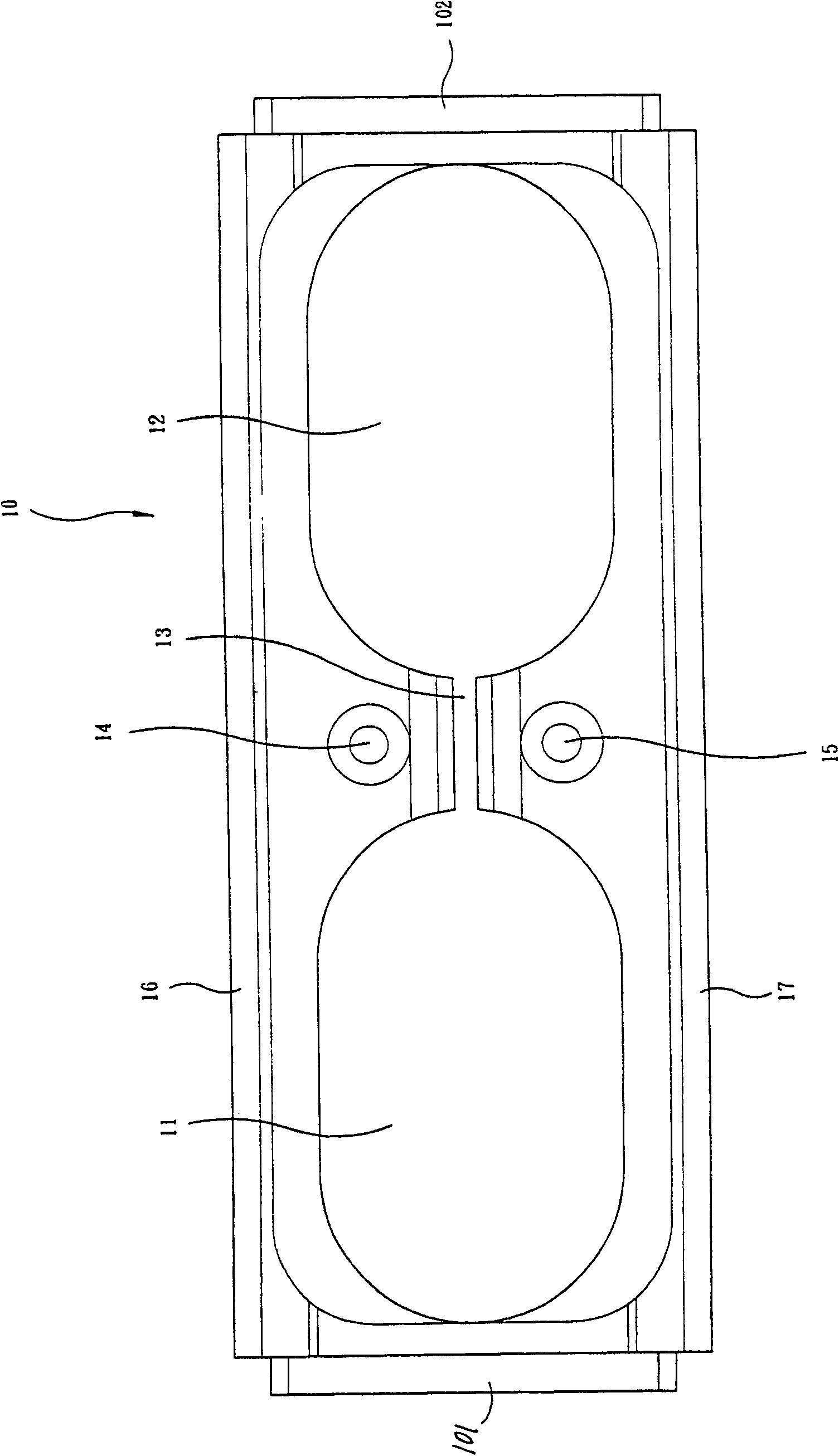

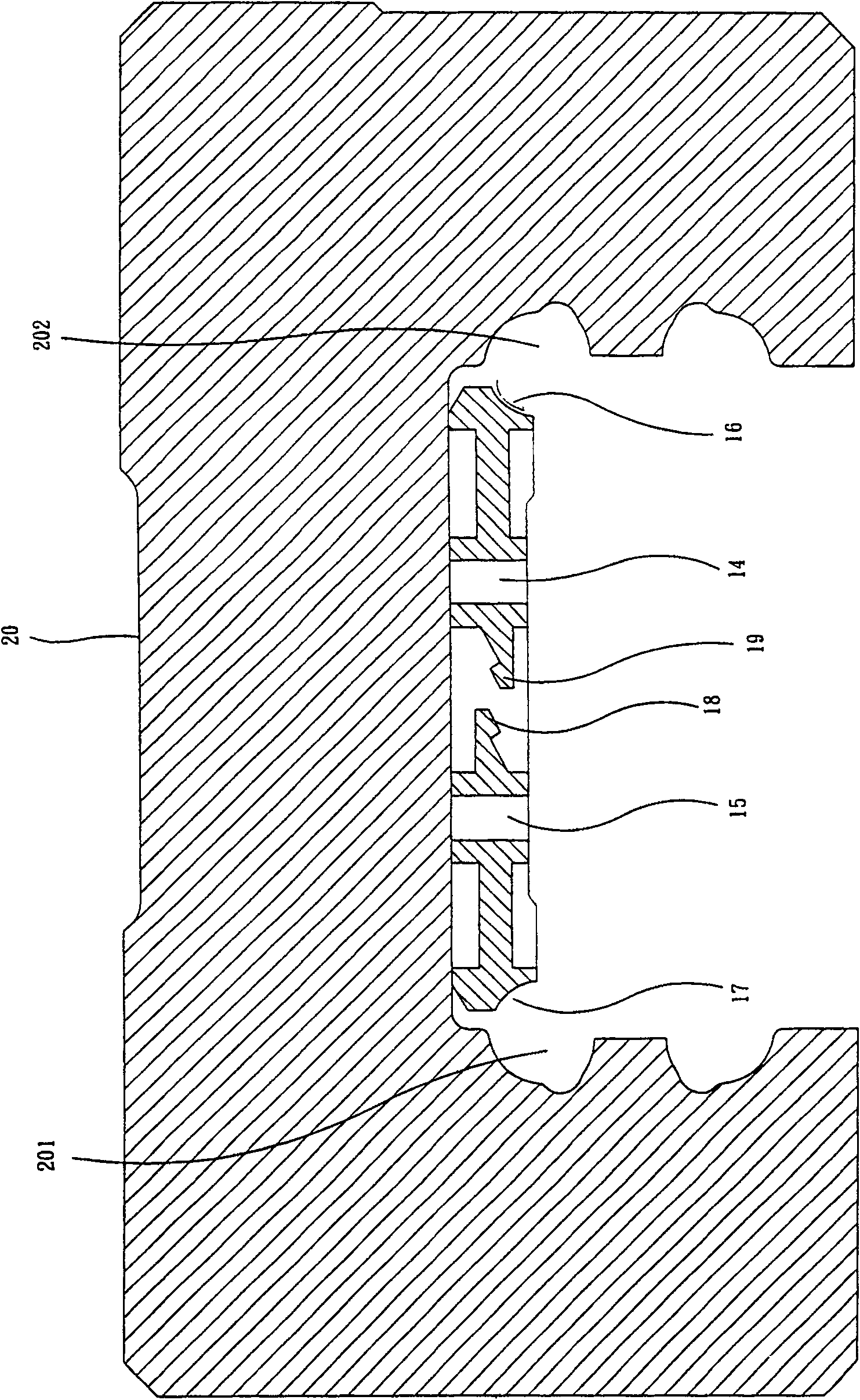

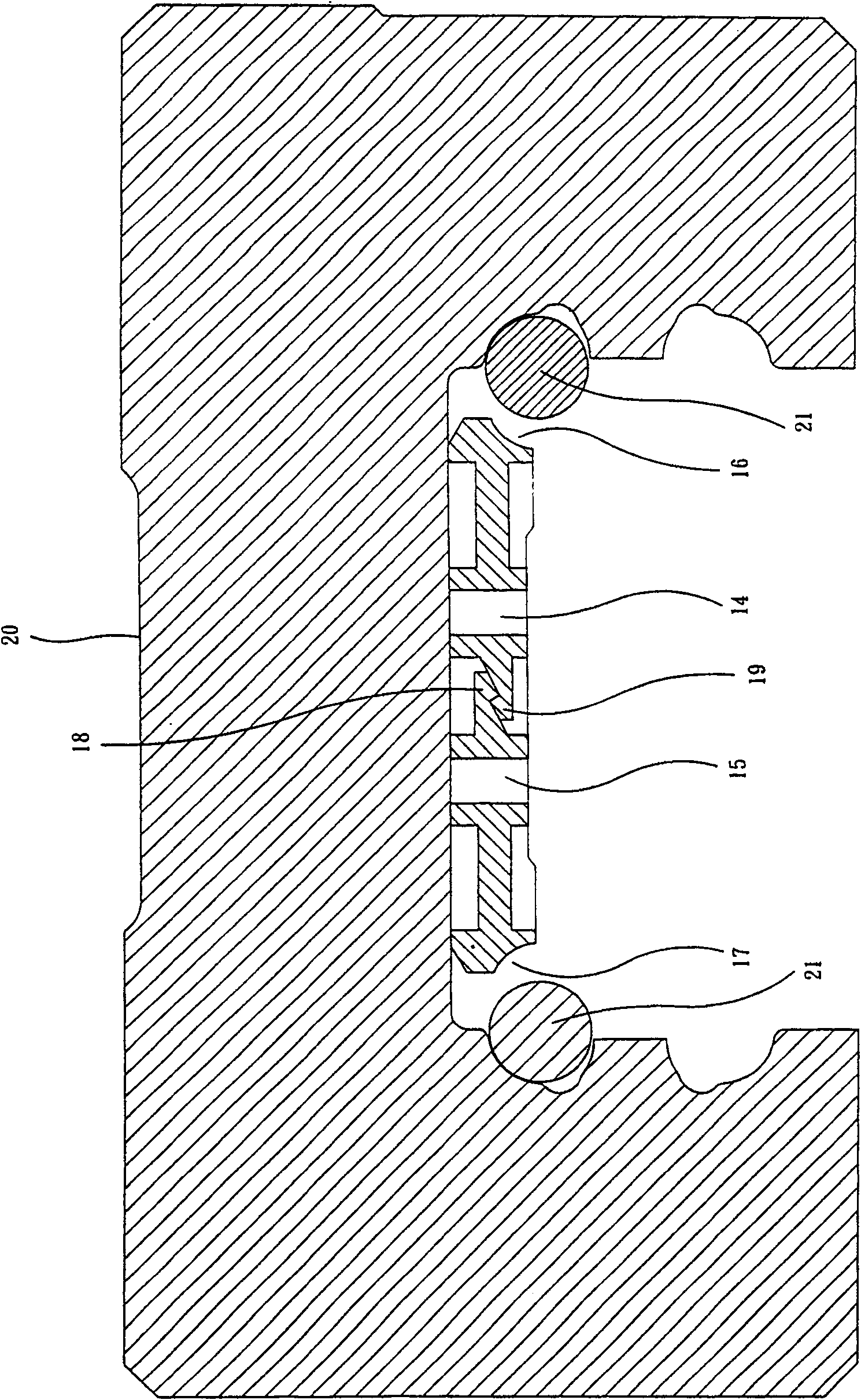

[0042] see Figure 3 to Figure 6 As shown, the retainer 40 of the present invention is inserted between the end caps 32, 34 at both ends of the slider 30, and a return element 33 is clamped between each end cap 32, 34 and the opposite side of the slider 30 (end cap 32 and The return element between the sliders 30 is not seen), and the other side of each end cover 32, 34 is provided with an oil scraper 31, 35. After the above-mentioned components are assembled, they are nested on the slide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com