Device and method for disengaging detecting safe coupling of roller mill main axle

A technology of safety coupling and detection device, which is applied to the driving device of metal rolling mill, safety equipment of roll, length measuring device, etc., which can solve the problems of increased grinding amount of work roll, scratches, and affecting enterprise benefits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

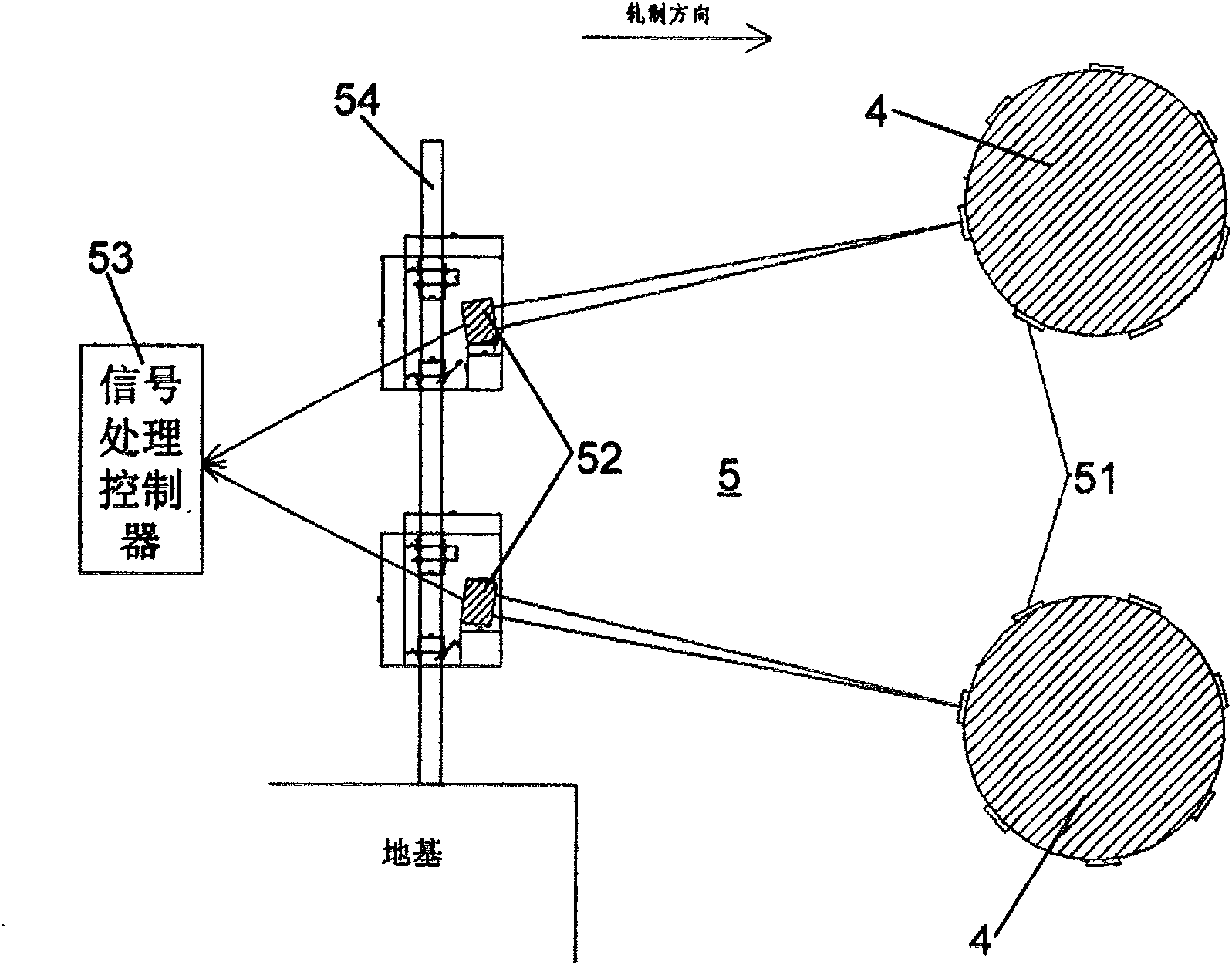

[0036] see image 3 As shown, the disengagement detection device 5 of the safety coupling of the main shaft of the rolling mill of the present invention includes a reflector 51, a photoelectric component 52 and a signal processing controller 53, and reflectors 51 of equal size and number are respectively arranged on the upper and lower sides of the rolling mill. On the surface of the safety coupling 4 of the roller, there are at least two reflectors 51 on the disengagement side surface of each safety coupling 4, and the number of reflectors 51 is selected by the installation position on the safety coupling 4 in addition. The limit and depends on the response speed of photoelectric components, the more the number, the faster the response time. In this embodiment, in order to avoid covering the screw holes on the safety coupling, a square polygonal reflector with a side length of 100 mm is selected as a reflector, and seven reflectors are evenly and equally divided around each s...

Embodiment 2

[0038]The steps of the method for detecting disengagement of the safety coupling of the main shaft of the rolling mill of the present invention are: during the operation of the rolling mill, use a photoelectric component to emit light to the disengagement side of the safety coupling; the photoelectric component selects two infrared beams of the same type The photoelectric components of the rolling mill are respectively arranged on the fence bars on the entrance side of the rolling mill about five meters away from the safety couplings of the upper and lower rolls of the rolling mill, and correspond to the safety couplings of the upper and lower rolls respectively. The fence bars are placed on On the foundation, most vibration factors can be eliminated. Then the reflected light of the reflective plate on the safety coupling is received by the photoelectric component, and a pulse signal is formed; the reflective plate is respectively set on the surface of the safety coupling of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com