Detaching and assembling tool for gate valve plate and seat

A valve plate and seat technology, which is applied in the field of gate valve plate and seat assembly and disassembly tools, can solve the problems that the valve seat cannot be disassembled and the operation is difficult

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

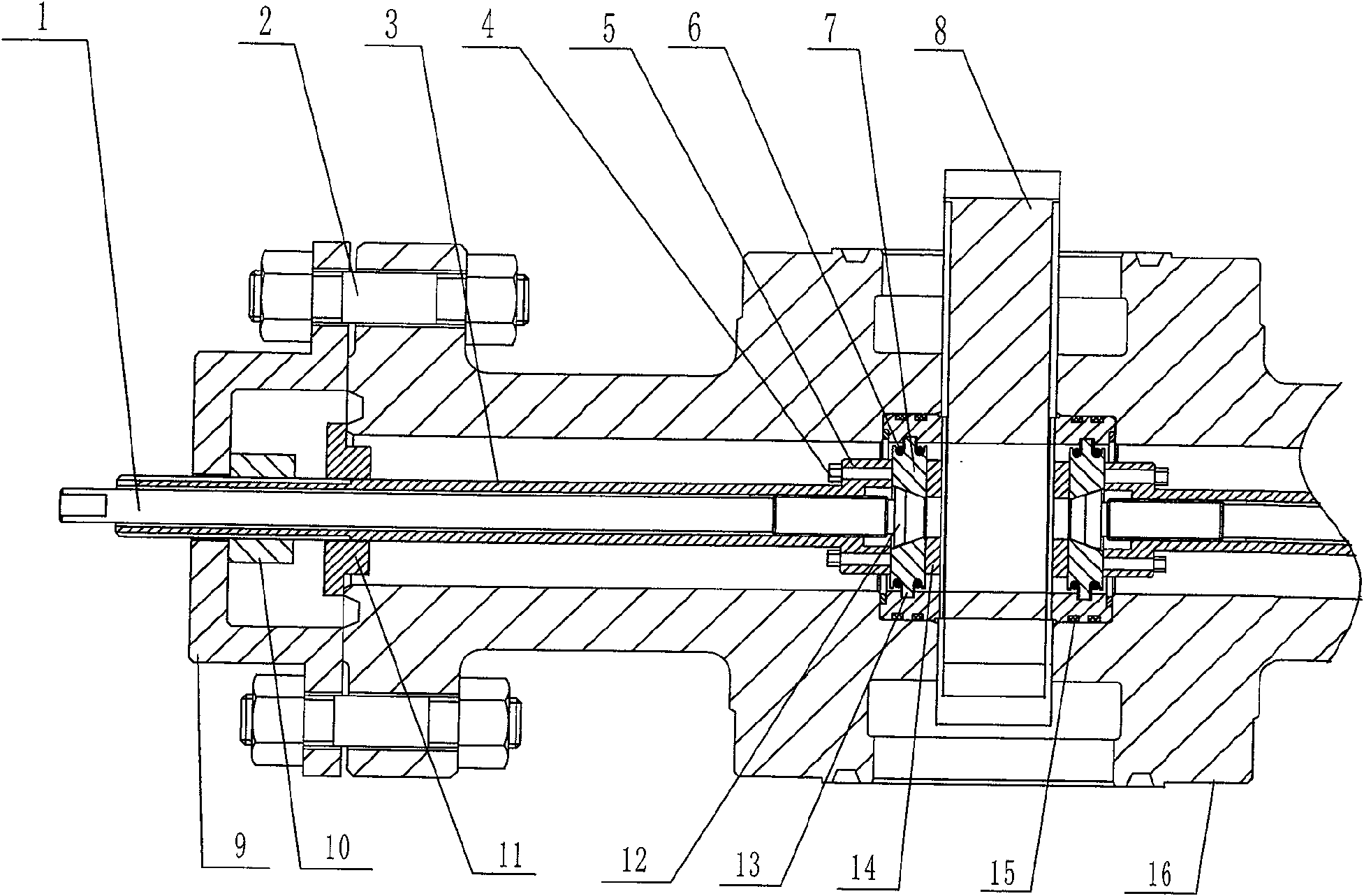

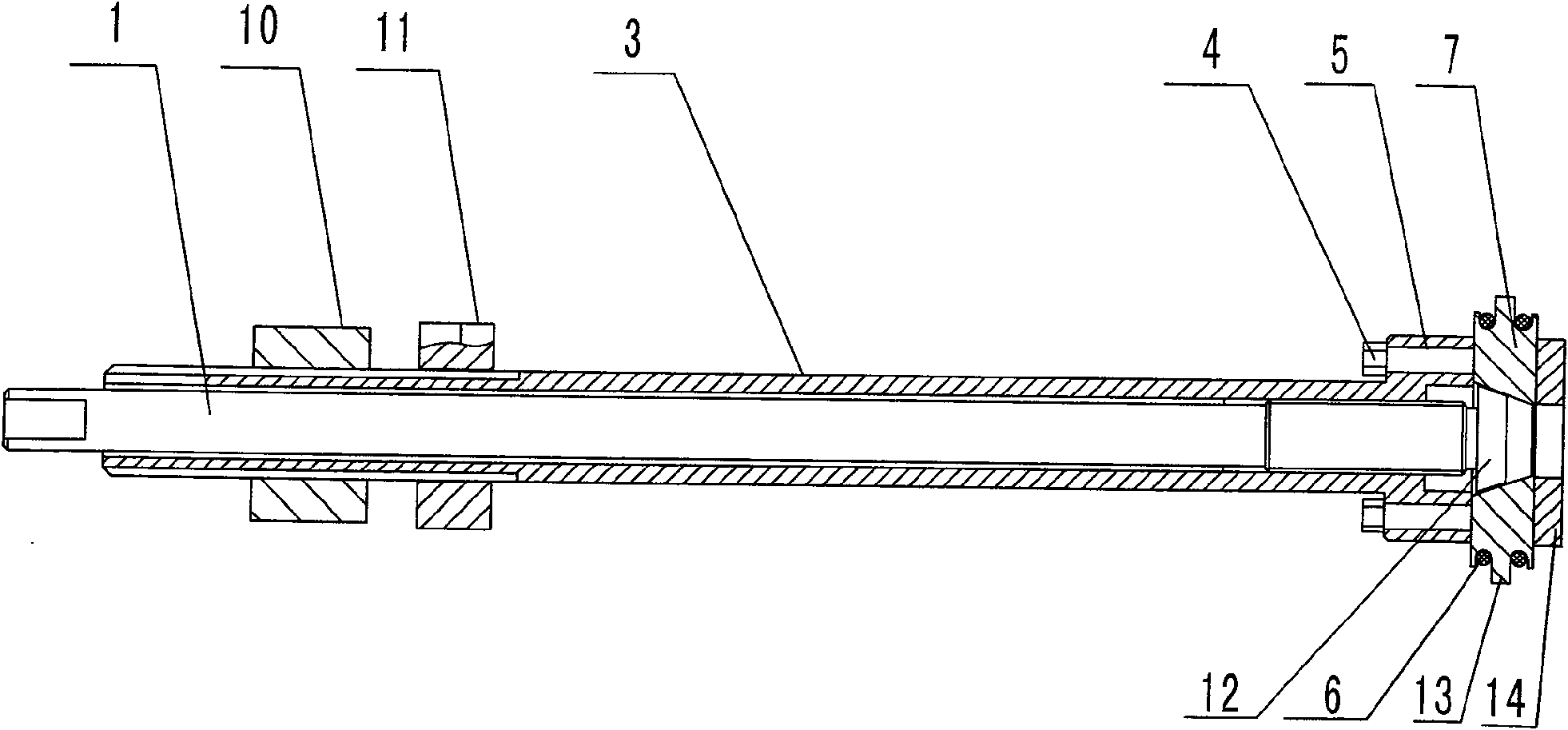

[0019] The present invention is achieved in that the present invention includes a push mechanism and an expansion mechanism, the push mechanism is composed of a push rod 1, a pull rod 3, a connecting bolt 4, a block 11, a nut 10, a pull rod seat 9 and a bolt 2, and the pull rod 3 It is hollow, and the push rod 1 is arranged in the pull rod 3, and the front end of the push rod 1 is provided with a conical body 12. The flange on the end face of the valve body is fixedly connected with the tie rod seat 9 by the bolt 2, the nut 10 and the stopper 11 are respectively turned on the tie rod 3 and sleeved on the tie rod 3;

[0020] The extrusion mechanism is composed of an expansion core block 7, an expansion core block seat 14, and an o-shaped rubber sealing ring 6. The expansion core block 7 is composed of two semicircles, or three semicircles; in the middle of the outer circle of the expansion core block 7 The expansion core block protrusion 13 is provided, and the expansion core b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com