Locking device for railway container flat car loading

A locking device and container technology, which is applied to railway car body parts, trucks, transport passenger cars, etc., can solve problems such as twist lock constraints are not firm, locking devices are not firm, and there are potential safety hazards, and achieve strong anti-theft function and structure Simple and beneficial to driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

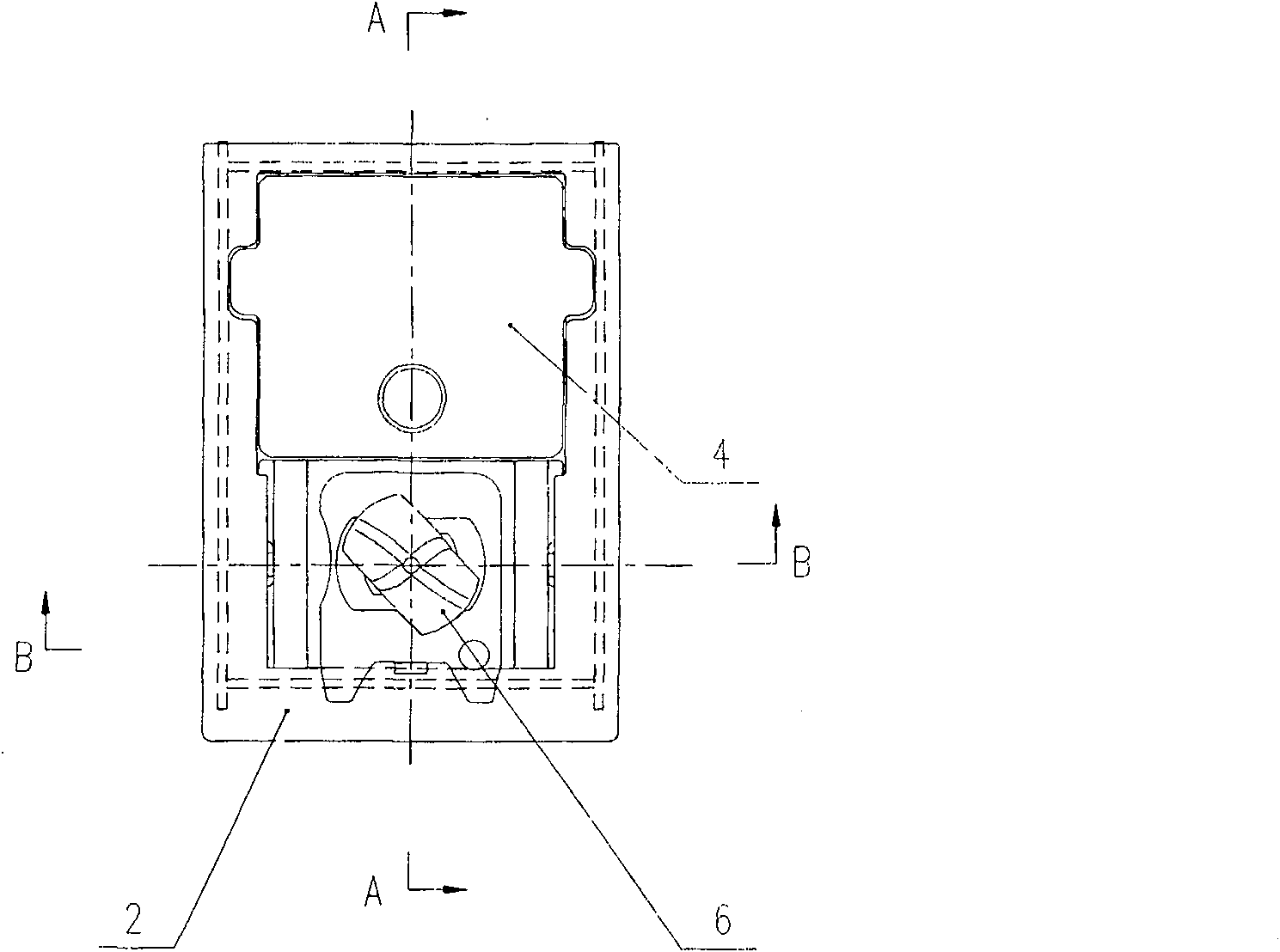

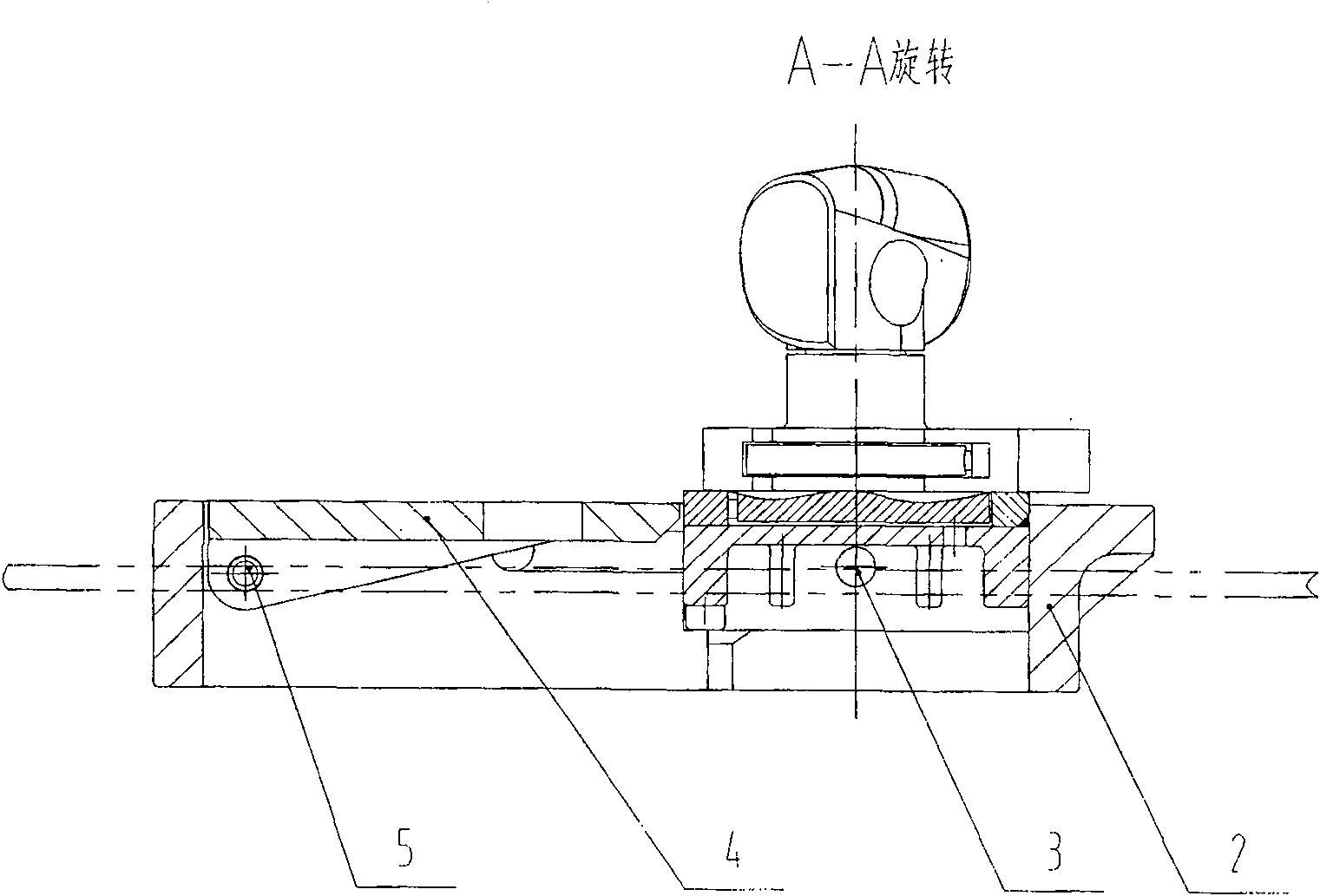

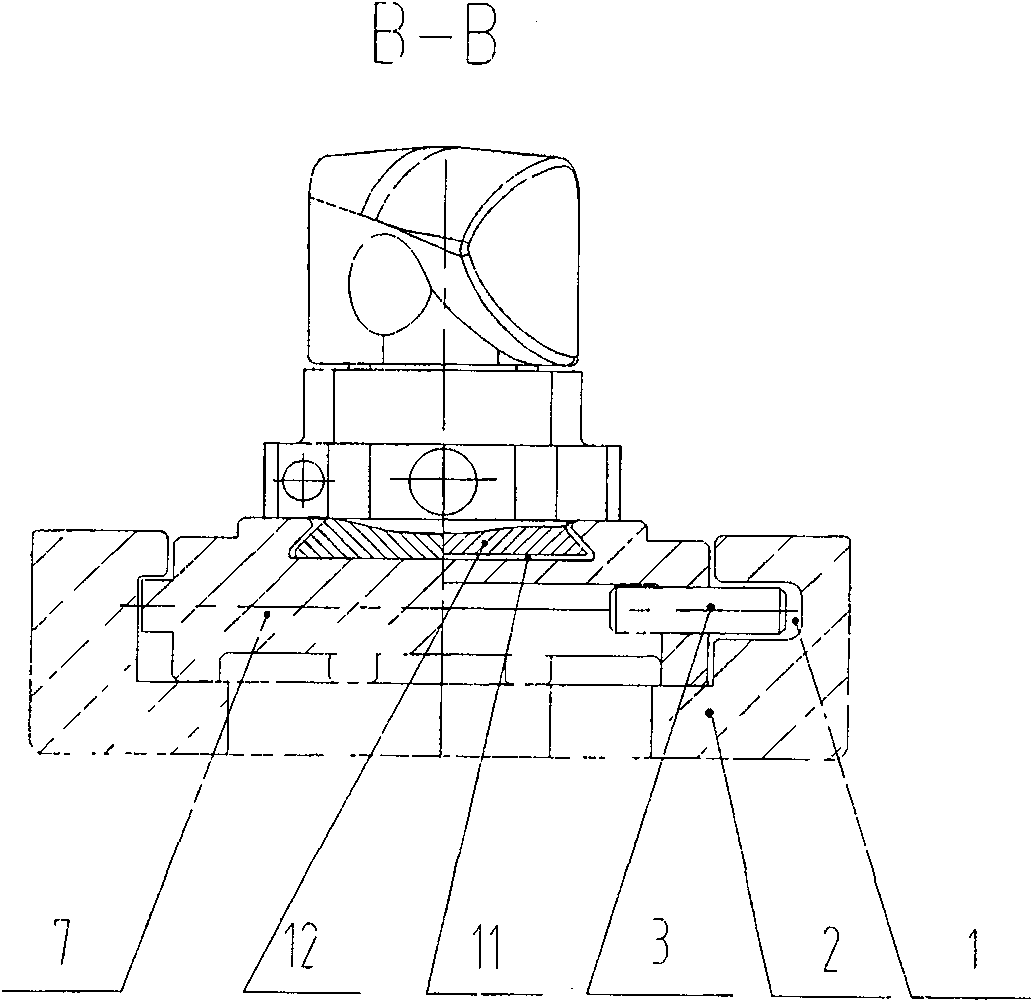

[0021] Referring to the accompanying drawings, the present invention includes a fully automatic twist lock 6, a lock head rotating shaft 3 and a baffle plate 4, and its key technology is:

[0022] The locking device also has a twist lock base 7, a dovetail groove 11 is formed on the top surface of the twist lock base 7, and a through hole is opened below the dovetail groove on the twist lock base 7;

[0023] The locking device also has a lock base 2, the middle part of the lock base 2 is a cavity, and a chute 1 is respectively opened on the inside of the lock base 2 on both sides;

[0024] There is a dovetail-shaped boss 12 at the bottom of the fully automatic twist lock 6, the dovetail-shaped boss 12 is embedded in the dovetail groove 11, the lock head rotating shaft 3 is inserted into the through hole of the turn lock base 7, and the lock head rotating shaft 3 and the turn lock base 7 points Fixed by welding, the two ends of the lock head rotating shaft 3 are respectively lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com