Gas path breaker

A technology for circuit breakers and air circuits, which is applied to high-voltage air circuit breakers, circuits, electrical components, etc., can solve problems such as insulation damage between live parts and grounding boxes, and achieve the effects of promoting miniaturization, preventing insulation damage, and suppressing density reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

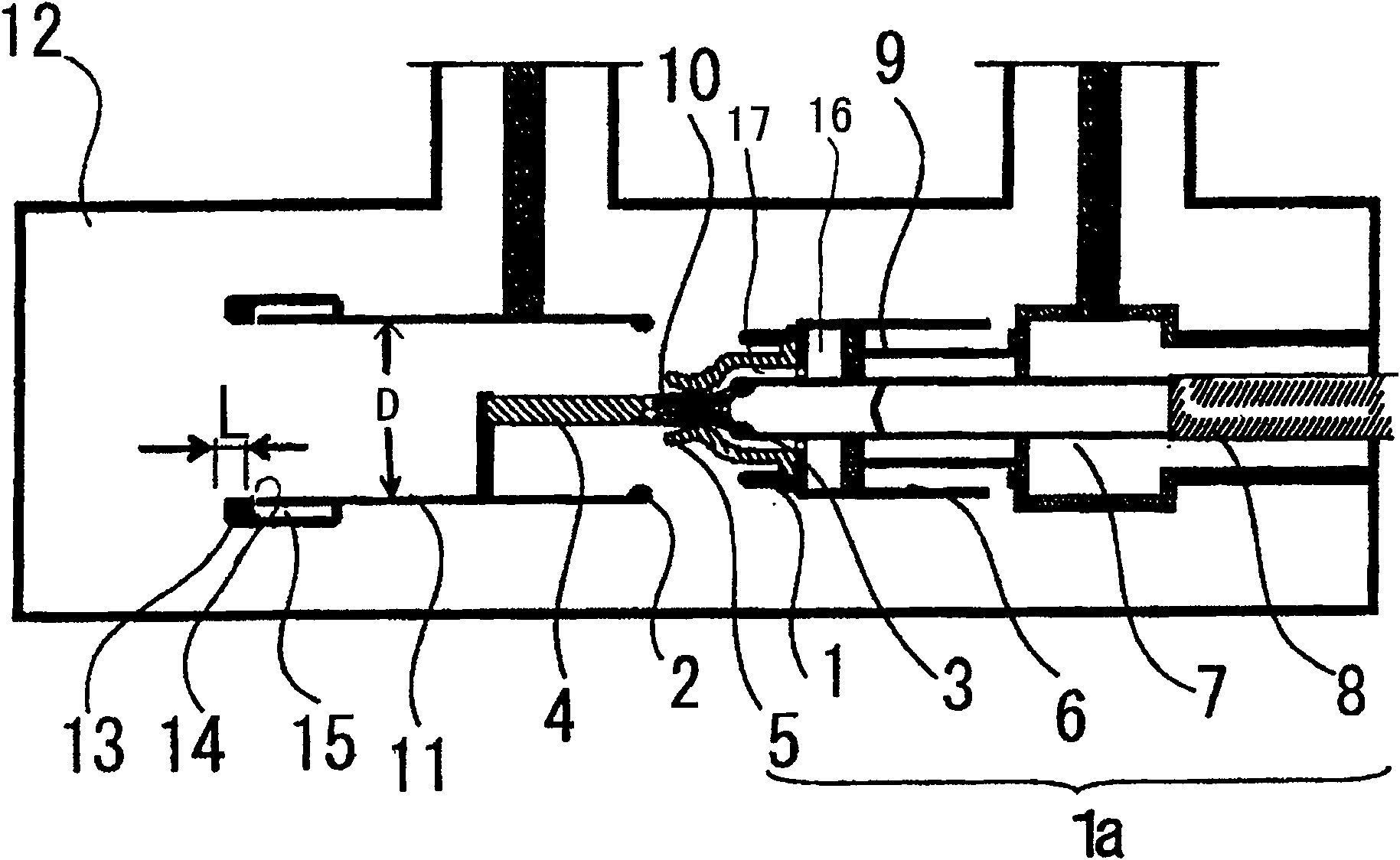

Image

Examples

no. 2 Embodiment approach

[0038] (structure)

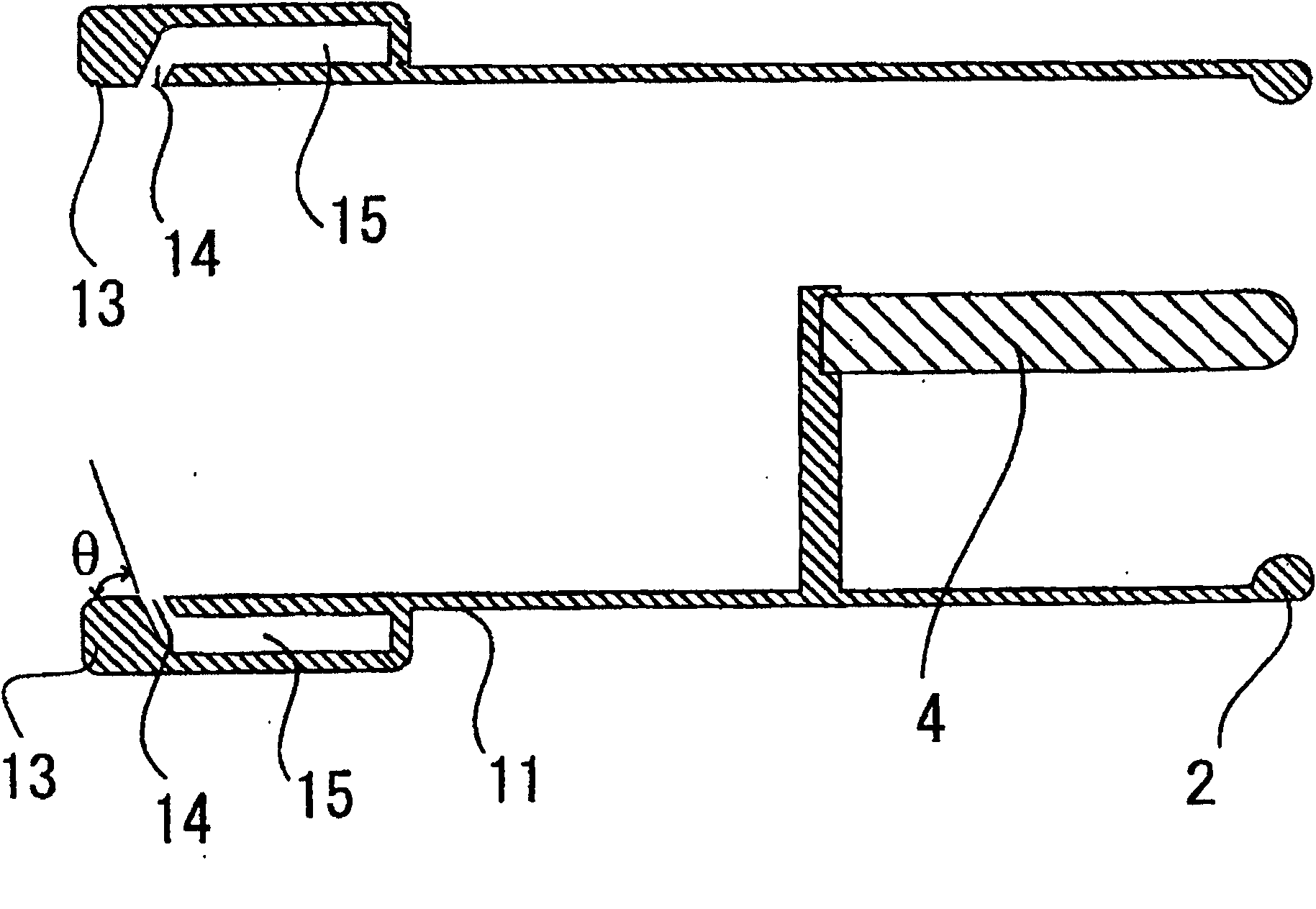

[0039] figure 2 It is a cross-sectional view showing a second embodiment of the present invention. The second embodiment is characterized in that the angle θ between the gas blowing port 14 and the exhaust tube 11 is inclined within a range of 30 degrees or more and 90 degrees or less.

[0040] (Effect)

[0041] In the second embodiment, by inclining the gas outlet 14 by θ with respect to the central axis of the exhaust pipe 11 , the following unique effects can be obtained. That is, by inclining the gas outlet 14 at an angle smaller than 90 degrees with respect to the central axis of the exhaust tube 11 , the gas in the pressure chamber 15 can easily reach the exhaust tube shield 13 . In addition, by inclining the gas outlet 14 at an angle greater than 30 degrees with respect to the central axis of the exhaust tube 11 , the high-pressure gas in the exhaust tube 11 can easily enter the pressure chamber 15 .

no. 3 Embodiment approach

[0043] (structure)

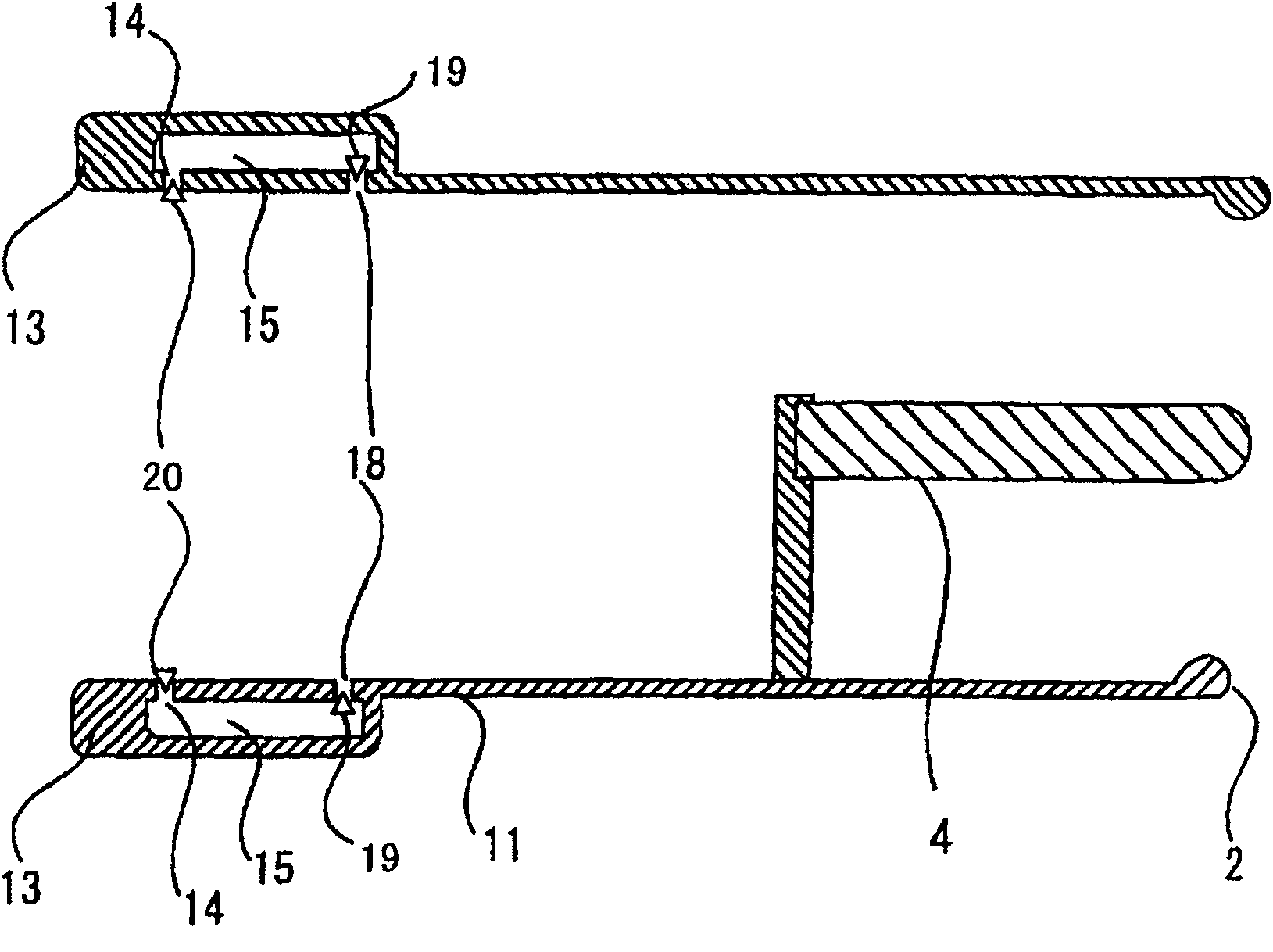

[0044] image 3 It is a cross-sectional view showing a third embodiment of the present invention. The second embodiment is characterized in that, on the pressure chamber 15, in addition to the gas outlet 14, on the upstream side of the hot gas flow from the gas outlet 14, image 3 In the middle, a gas inflow port 18 is provided on the right side. In addition, a check valve 19 for a gas inlet is provided in the gas inlet 18 so that the gas can only flow from the side of the exhaust cylinder 11 to the pressure chamber 15 . Furthermore, a check valve 20 for a gas blowout port is provided in the gas blowout port 14 so that the gas can flow from the side of the pressure chamber 15 to the direction of the exhaust tube 11 .

[0045] (Effect)

[0046] In this third embodiment, in addition to the effects of the above-mentioned first embodiment, the following unique effects can be obtained. That is, by providing the gas inlet check valve 19 at the gas inlet 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com