Control device for opening material door of oilseed-cracking machine

A technology of opening control and machine material, which is applied in the direction of fat oil/fat production, fat production, grain processing, etc. It can solve the problems of not being able to absorb dross such as iron and other material flow, and affect the service life of the crushing roller, so as to prolong the life and prevent over-opening. The effect of size, protection and longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

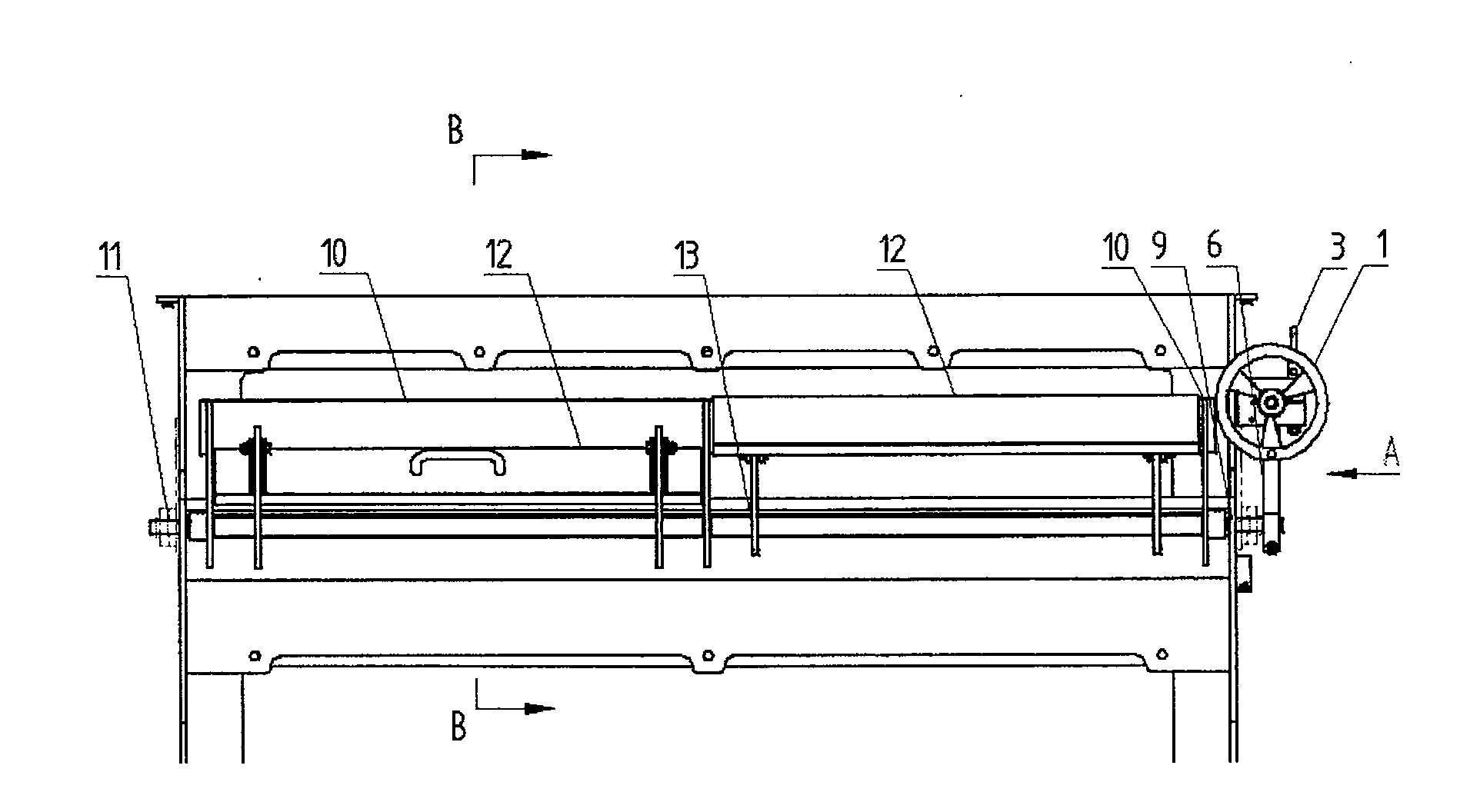

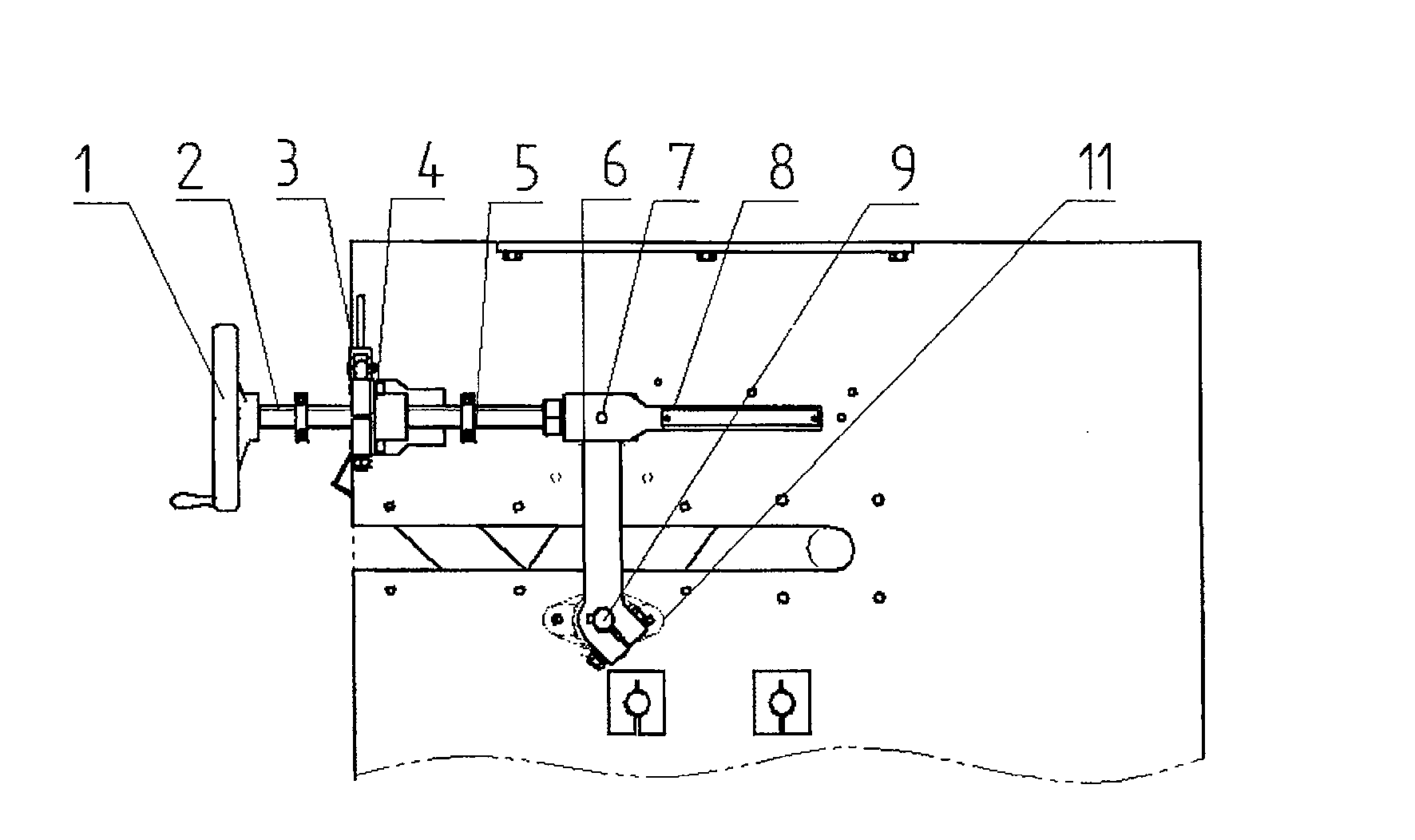

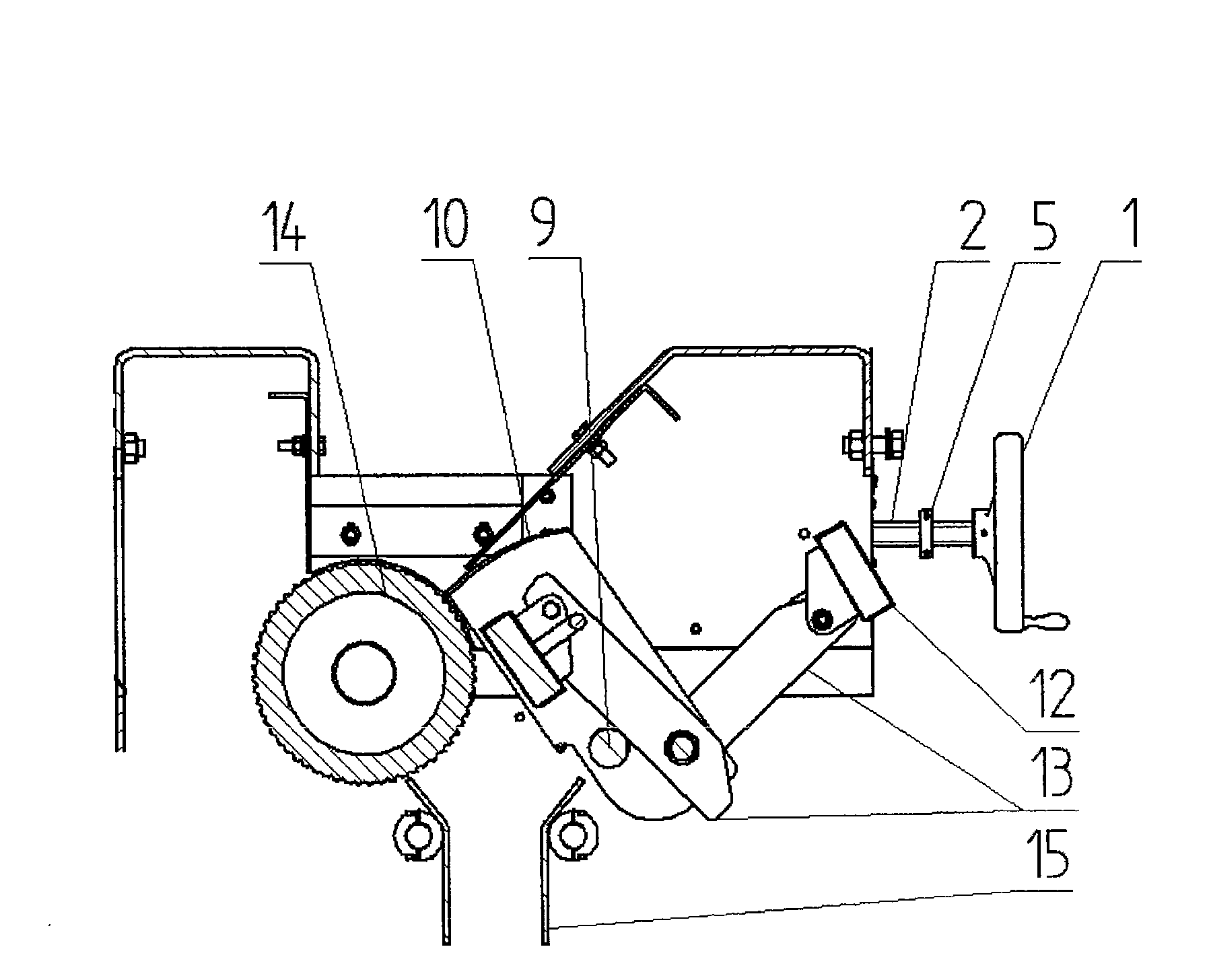

[0015] Further illustrate the present invention in conjunction with accompanying drawing and embodiment, as figure 1 As shown, the present invention has two self-rotatable magnet blocks 12 installed on two rotatable magnet frames 13; it can rotate together with the opening of the material door 10; the opening of the material door 10 is the material door 10 and the feed roller 14 The distance between them is realized by the rotation of the connecting rod 6 and the crank 2 through the handwheel 1 to open the material door 10; the material door 10, the magnet 12 and the magnet frame 13 are installed on both sides of the frame, relying on the shaft heads 9 at both ends on the bearing 11 turn.

[0016] Such as figure 2 , 3 As shown, the opening size of the material door 10 is controlled by two movable limit blocks 5 on the left and right of the screw connecting rod 2. When the position is adjusted, the limit block 5 is tightened, and the crank 2 is fixed on the On the side plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com