Pulse width modulation (PWM) control device and driving method thereof

A technology of pulse width modulation and control device, which can be applied to controllers with pulse train output signals, electric controllers, etc., and can solve the problem of high loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the above-mentioned purpose, features and advantages of the present invention more obvious and easy to understand, the preferred embodiments are specifically cited below, together with the accompanying drawings, and are described in detail as follows:

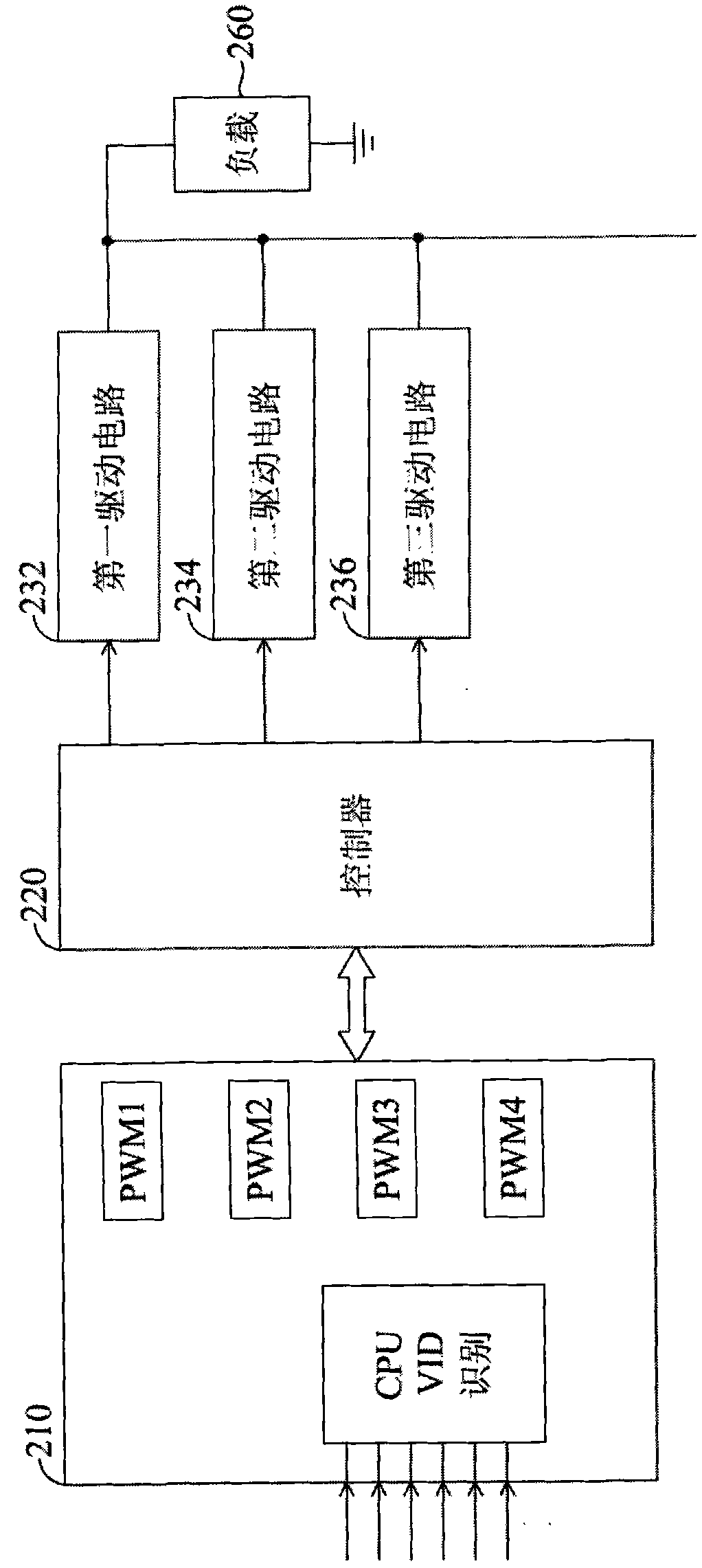

[0013] figure 2 A structural diagram illustrating a pulse width modulation (PWM) control device according to an embodiment of the present invention. The PWM control device includes a PWM device 210 and a controller 220 .

[0014] PWM device 210 is a chip, integrated circuit or microprocessor that provides multi-phase PWM signals. The controller 220 is connected to the PWM device 210 and the array drive circuit, receives the PWM signal from the PWM device 210, and transmits it to the controlled first drive circuit 232, second drive circuit 234, and third drive circuit 236 after calculation and processing, respectively. To achieve the control purpose of the present invention. The controller 220 may als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com