Synthetic resin pipe

A synthetic resin and inner tube technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of reduced flexibility, increased weight of synthetic resin pipes, and failure to achieve smooth outer surface of synthetic resin pipes, etc., to achieve Effects of improving smoothness and improving compressive flat strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, the present invention will be described in detail based on embodiments of the drawings.

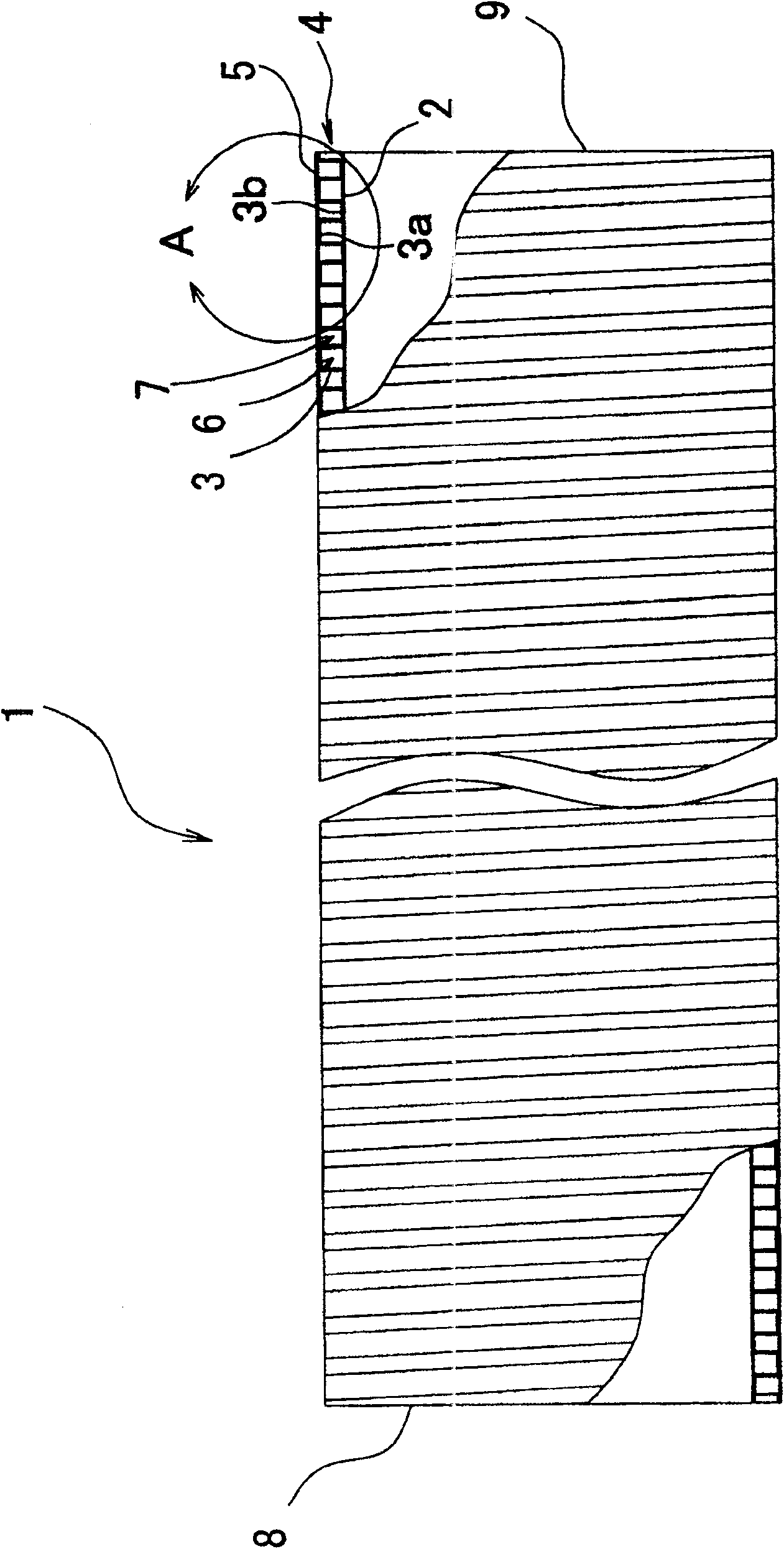

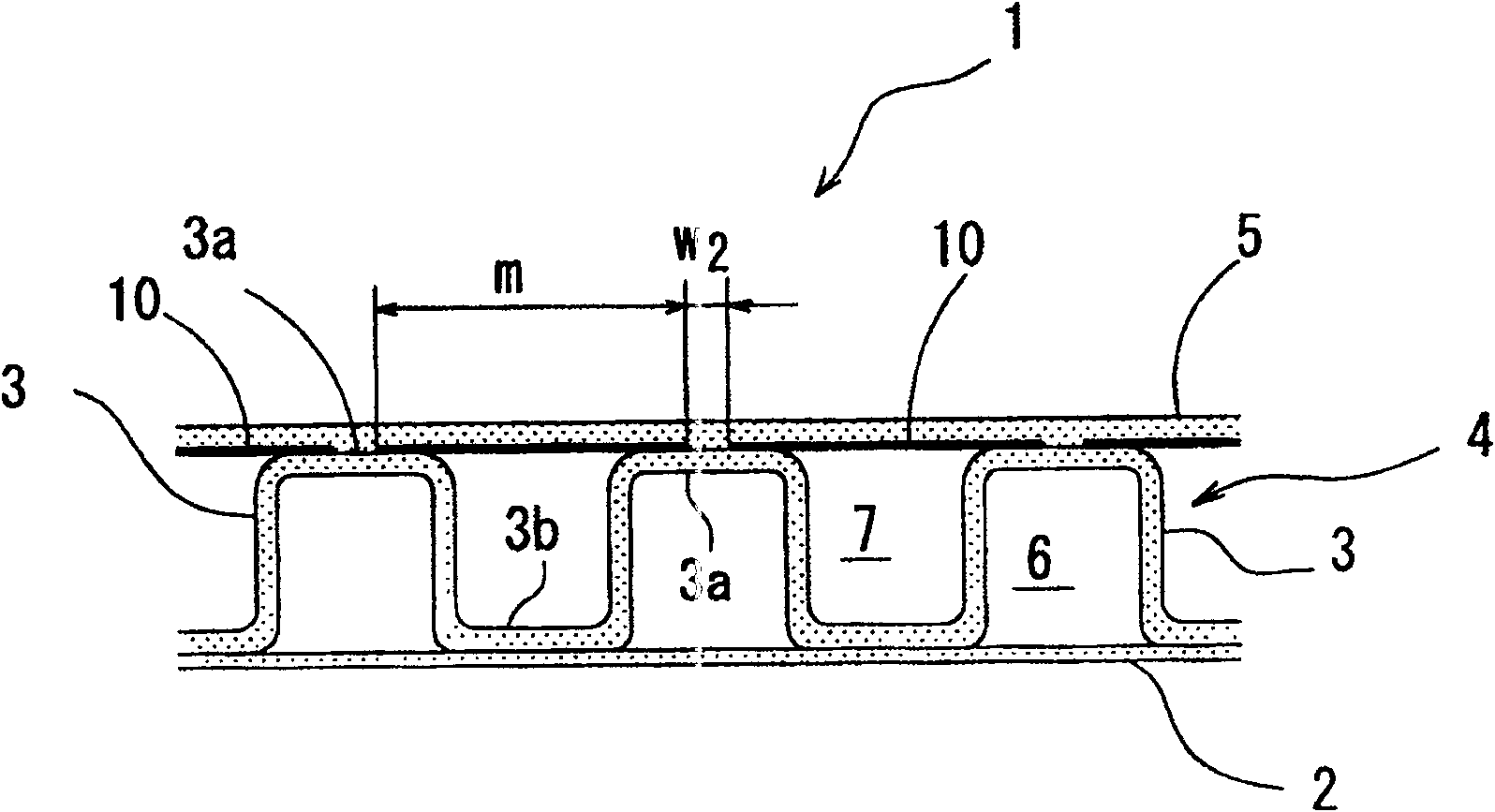

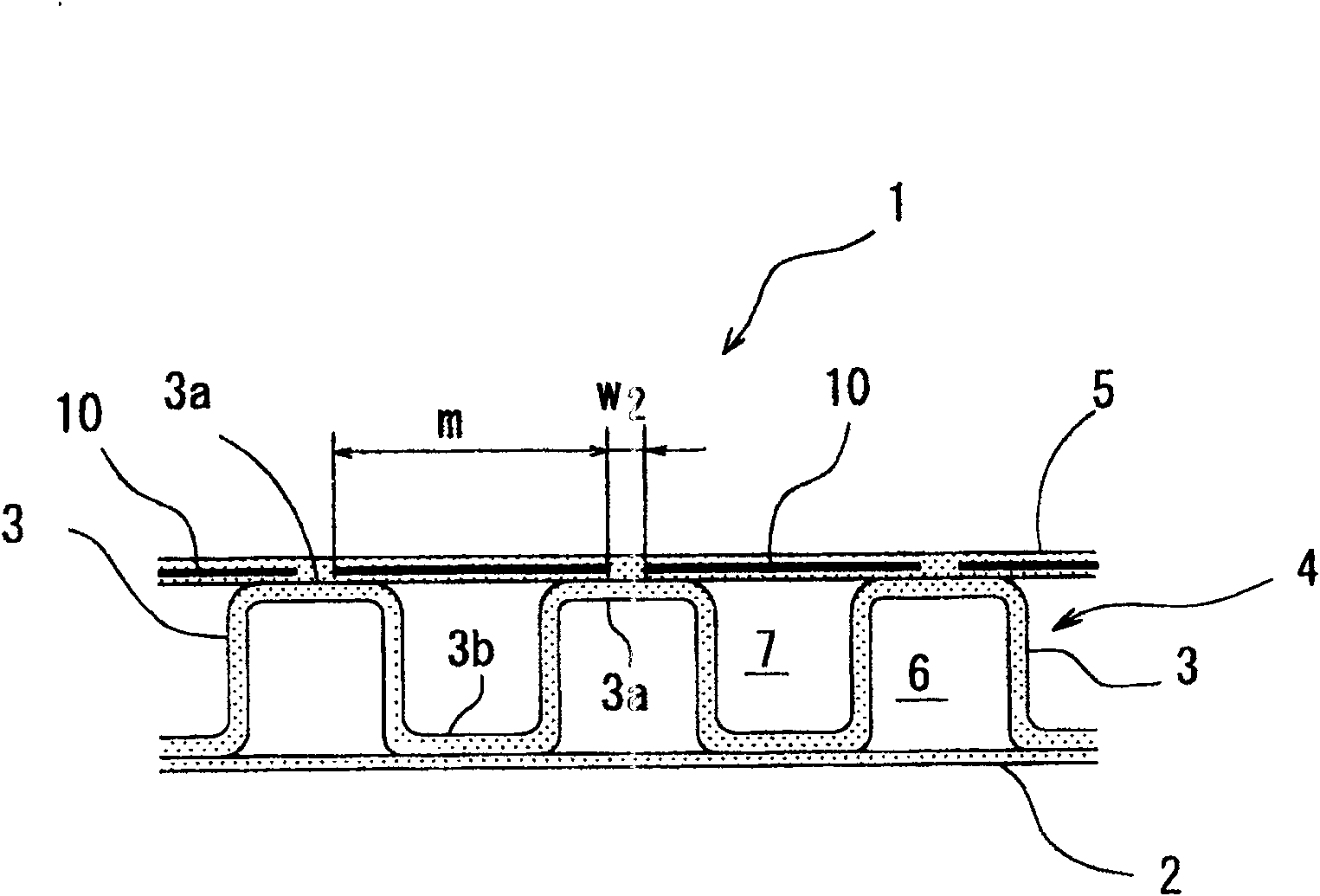

[0043] a Synthetic resin tube in which the outer tube with the outer tube conformal part is formed on the whole tube

[0044] figure 1 It is a figure which shows the whole structure of the synthetic resin tube of this invention in the state which partially cut out the cross section.

[0045] The synthetic resin tube 1 has an inner tube 2 with a smooth inner surface by winding a strip-shaped synthetic resin, and spiral reinforcements 4 are formed by spirally forming protrusions 3 at a predetermined pitch on the trunk outer wall of the inner tube 2 . Peak portions 3 a and valley portions 3 b are thus formed alternately in the tube axis direction on the outer surface of the inner tube 2 .

[0046] Moreover, the outer tube 5 is formed so that the crest part 3a of these protrusions 3 may be connected.

[0047] In addition, 6 in the figure shows the hollow part separated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com