A low resistance/high B value slice heat sensitive resistor and its making method

A technology for thermistors and manufacturing methods, applied in the direction of resistors with negative temperature coefficients, etc., to achieve the effects of ensuring accuracy, low manufacturing costs, and facilitating mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

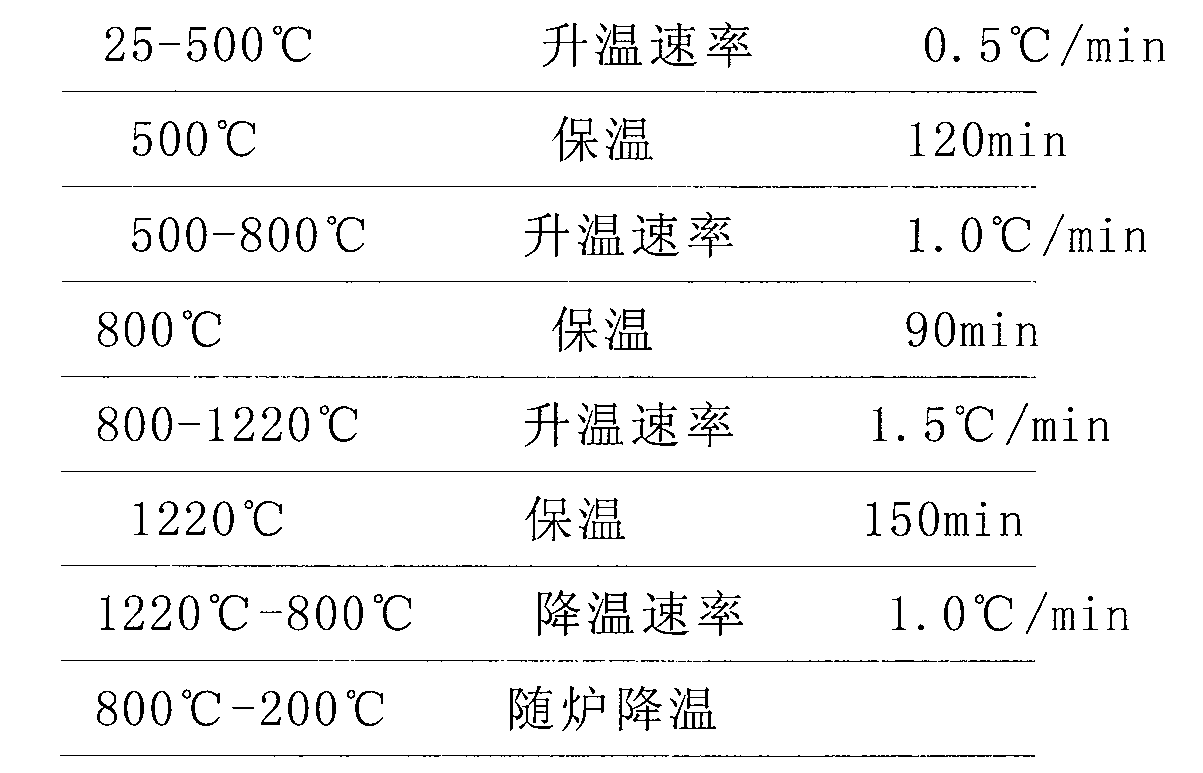

Method used

Image

Examples

Embodiment 1

[0021] 1. Preparation of low-resistance film

[0022] Take chemically pure (C.R) MnO 2 , NiO, CuO and CaO are weighed in a weight ratio of 43.845%: 18.834%: 34.058%: 3.267%, and ZrO with a diameter of Φ6 2 Ball, according to material: water: ball=1.0: 1.1: 1.5 (wt) ground on the planetary ball mill for 12 hours, dried at 90°C, and passed through a 200-mesh sieve, and put the sieved powder into a ceramic bowl 700°C / 2 hours pre-calcination; the powder after pre-calcination is put into the second ball mill for 16-18 hours (the method is the same as the first ball mill). The powder after the second ball milling was dried and passed through a 250 mesh sieve.

[0023] 2. rolling film

[0024] Add 40-50%wt PVA glue solution (solution concentration is 20%) to the powder, stir well, and keep 12 hours fermentation at normal temperature with relative humidity of 95%. The fermented slurry is directly put into the rolling film for rolling, and the gap of the rolling machine is constant...

Embodiment 2

[0037] Using the same process as in Example 1, the green thickness of the low-resistance diaphragm is taken as 8mm, the green thickness of the high B-value diaphragm is taken as 0.2mm, the total thickness after compounding is 1.0mm, and cut into 0603 chips after sintering , make terminal electrodes according to the conventional method, and the results measured in the constant temperature bath are as follows (statistics based on 100 chips)

[0038] R25 / Ω B25 / 50 / K H / mw C / sec ΔR / R / % ΔB / B / %

[0039] 50.8 3485 3.58 ±7 ±0.7

Embodiment 3

[0041] With the same process and method of Example 1, the formula of the high B value diaphragm is taken as MnO 2 :Co 3 o 4 :CuO:TiO:Nb 2 o 3 =62.5%: 23.565%: 8.0%: 3.168%: 2.767%, the green thickness of the low-resistance diaphragm is 5mm, the green thickness of the high B value film is 0.1mm, the green thickness of the composite diaphragm is 1.1mm, and the sintering After cutting into 0402-sized chips, make terminal electrodes according to conventional methods. The test results are as follows (statistics based on 100 chips)

[0042] R25 / Ω B25 / 50 / K H / mw C / sec ΔR / R / % ΔB / B / %

[0043] 302.2 3942 2.5 8.0 ±7.2 ±1.0

[0044] The results of Example 1, Example 2 and Example 3 above indicate that the technology provided by the present invention can conveniently realize low resistance / high B value chip NTCR. Compared with the chip NTCR with multilayer structure, it has lower resistance value and higher B value, and the process is simple and the manufacturing cost is low. The tec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com