Governor mechanism for stock guide of horizontal roller mill

An adjustment mechanism and horizontal roller milling technology, which is applied in the field of horizontal roller milling, can solve the problems of affecting the normal operation of equipment, being susceptible to dust erosion, and reducing work efficiency, and achieves compact structure, strong work reliability, and improved work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

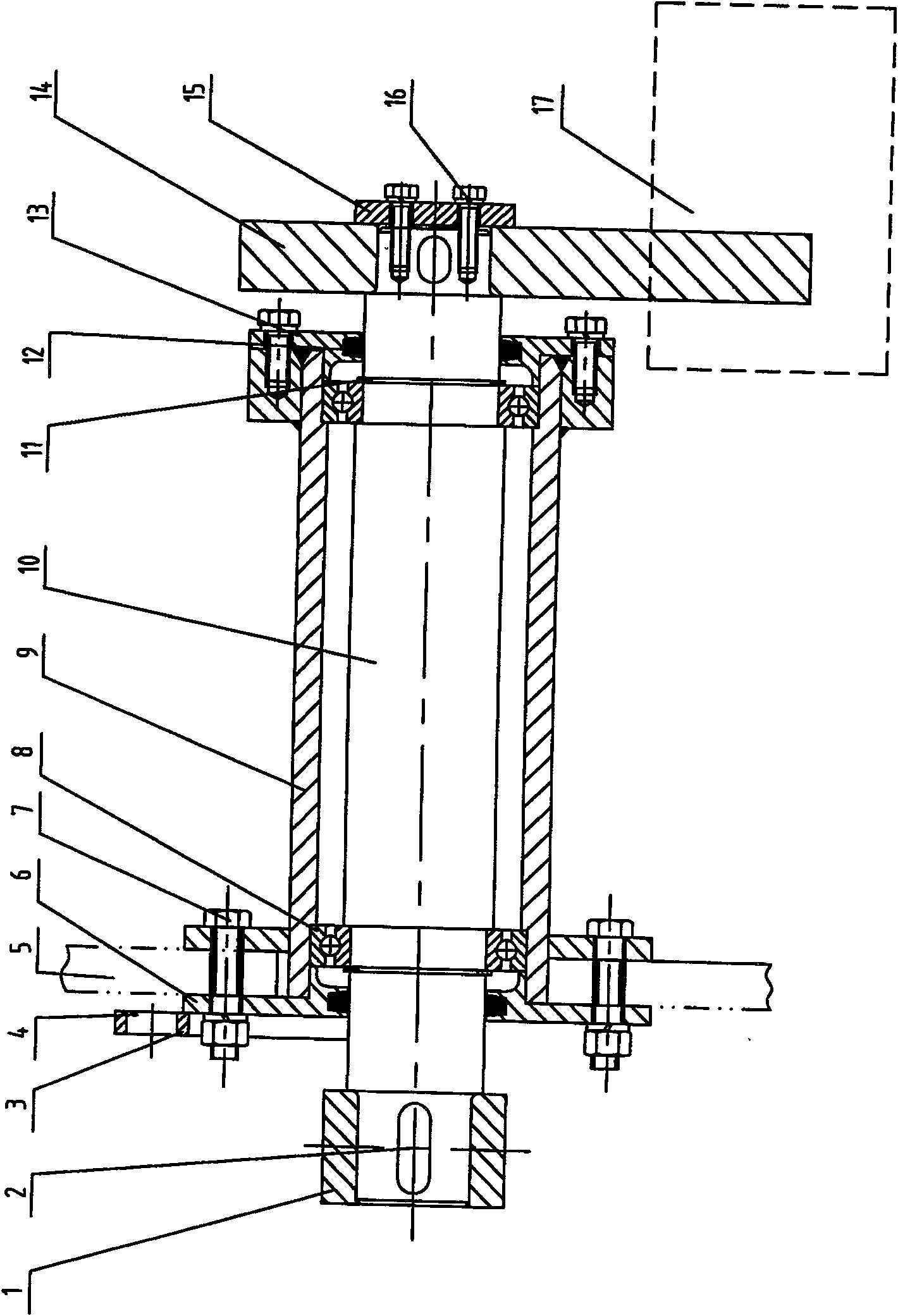

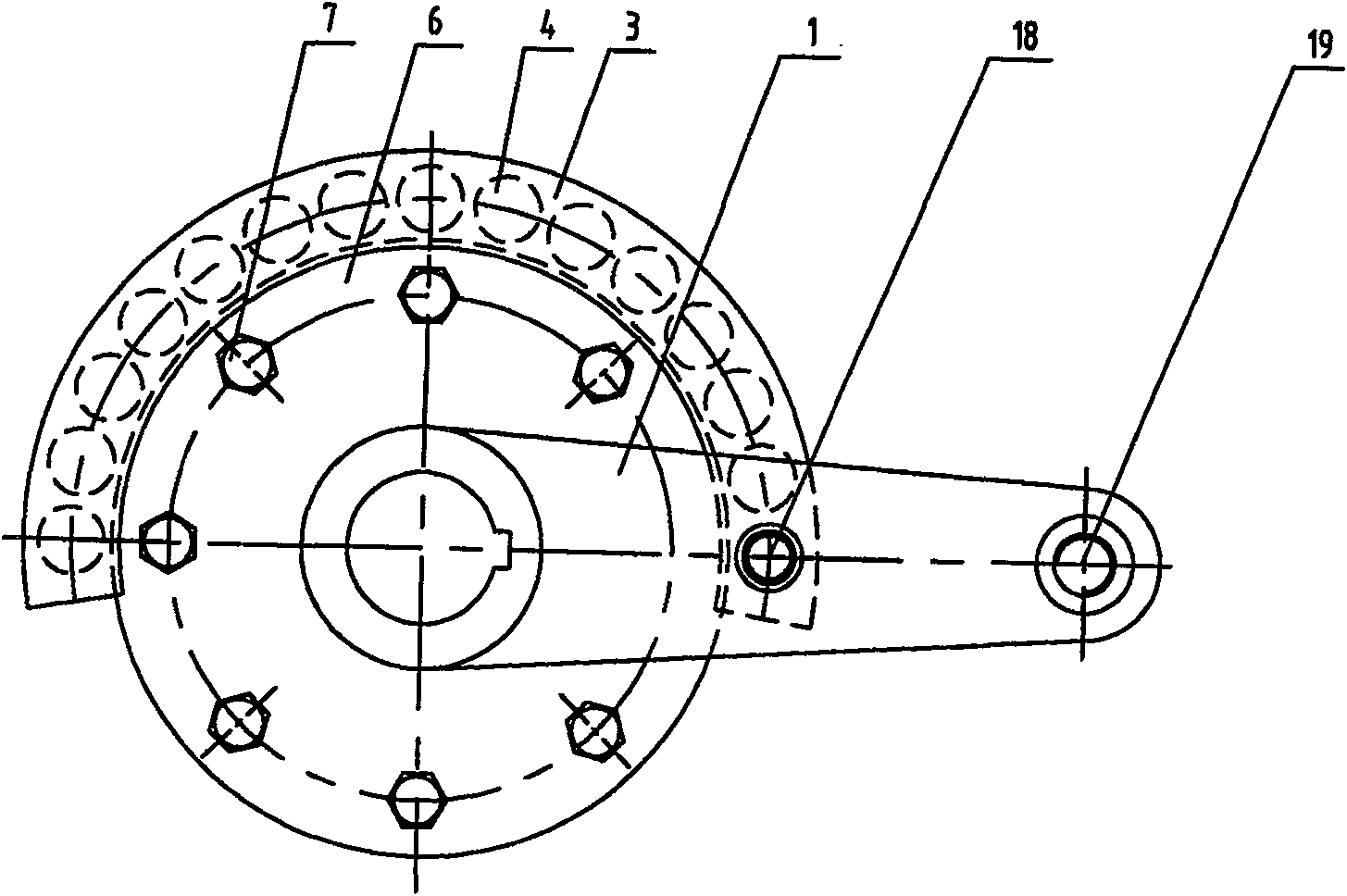

[0013] The present invention includes a rotating shaft 10, an eccentric wheel 14, a rocker arm 1, a dial 3 and a shaft sleeve 9; one end of the rotating shaft 10 passes through the end cover 5 of the horizontal roller mill, one end is placed in the horizontal roller mill, and the other end of the surface is in the horizontal roller mill. Roll mill outside. The inner end of the rotating shaft 10 is equipped with an eccentric wheel 14 in contact with the material guide plate 17 through the baffle plate 15 and the locking screw 16, and the contact point between the eccentric wheel 14 and the material guide plate 17 deviates from the axial and radial direction of the material guide plate 17 axis. One end of the rocking arm 1 is sleeved on the outer end of the rotating shaft 10, and is fixed by the key 2; the other end of the rocking arm is equipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com