Grinding roller mechanism device

A mechanism device and technology of grinding rollers, applied in the field of grinding rollers, can solve the problems of insufficient grinding force and large consumption of metal materials, and achieve the effects of long service life, low wear and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

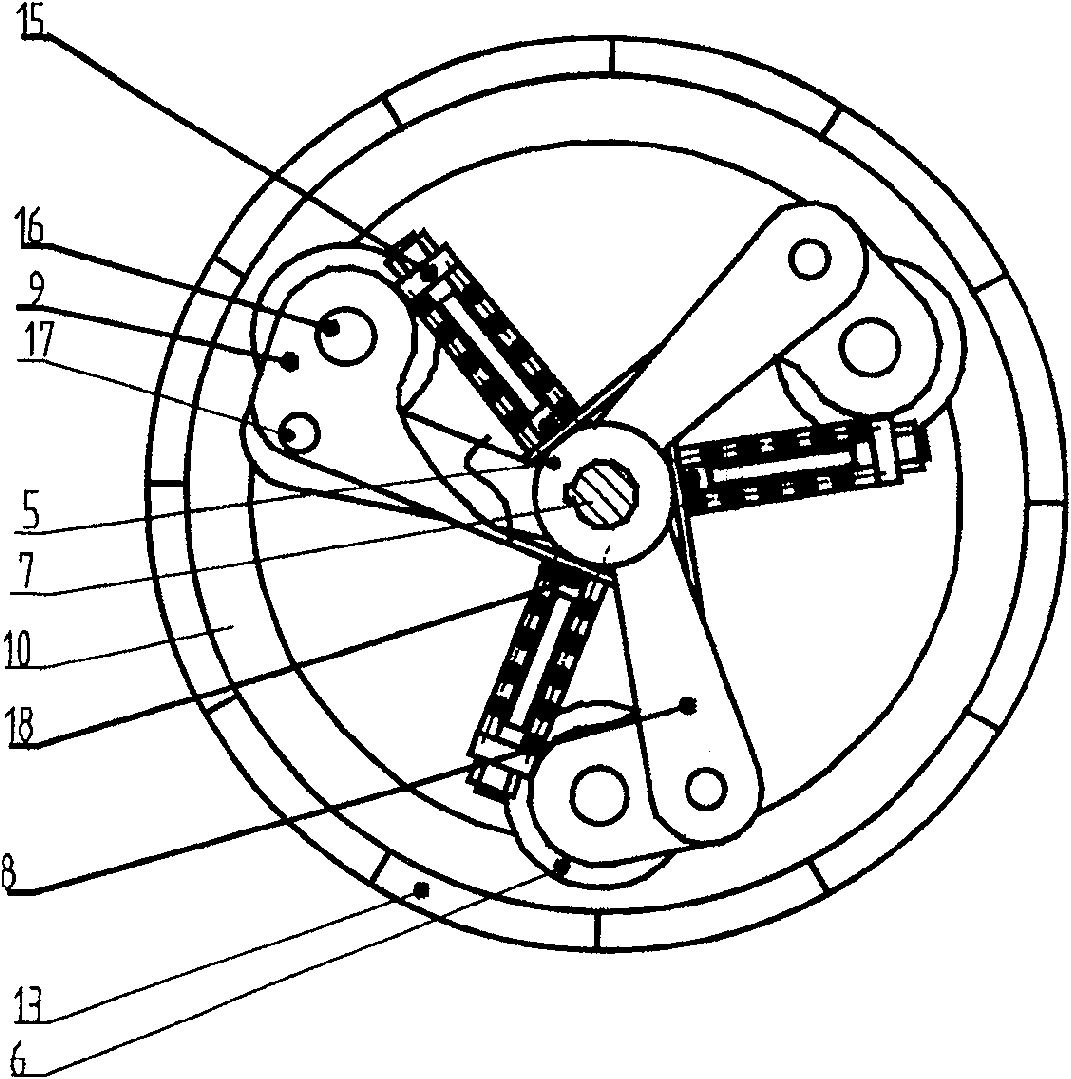

[0013] Embodiment 1: The grinding roller mechanism has a rotor 5, a shaft hole is arranged in the center of the rotor 5, and a rolling working device is hinged on the rotor.

[0014] The rolling working device has a connecting rod 9, which is hinged with the support 8, and one end of the connecting rod is connected with a roller pressure regulator, and the other end is connected with a grinding roller.

[0015] The connecting rod is a crank, and there is a roller gap adjuster between the end of the connecting rod and the rotor.

[0016] The roller pressure regulator is a spring device 15 or a hydraulic device, and the spring device has a spring and a bolt, and the spring is positioned at the outside of the bolt.

[0017] Grinding roller gap adjuster is the limit screw 18 that is connected on the connecting rod.

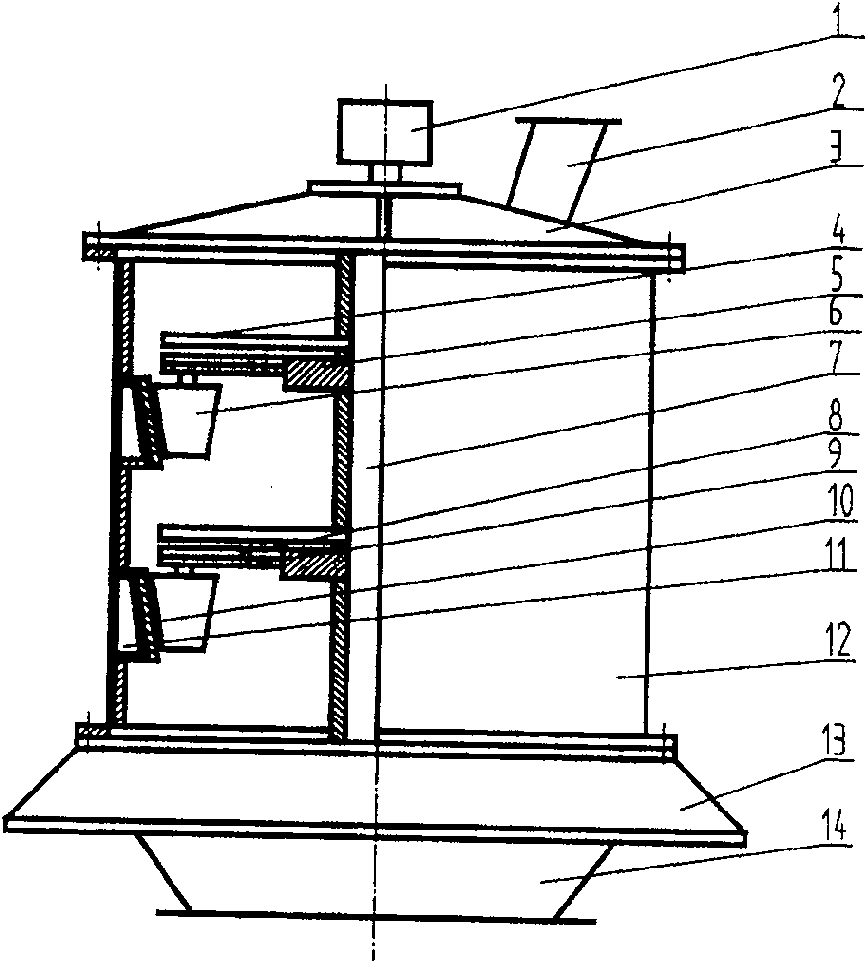

[0018] exist figure 2 , discloses a working device in which the grinding roller mechanism device of the present invention is installed on a grinding roller machine...

Embodiment 2

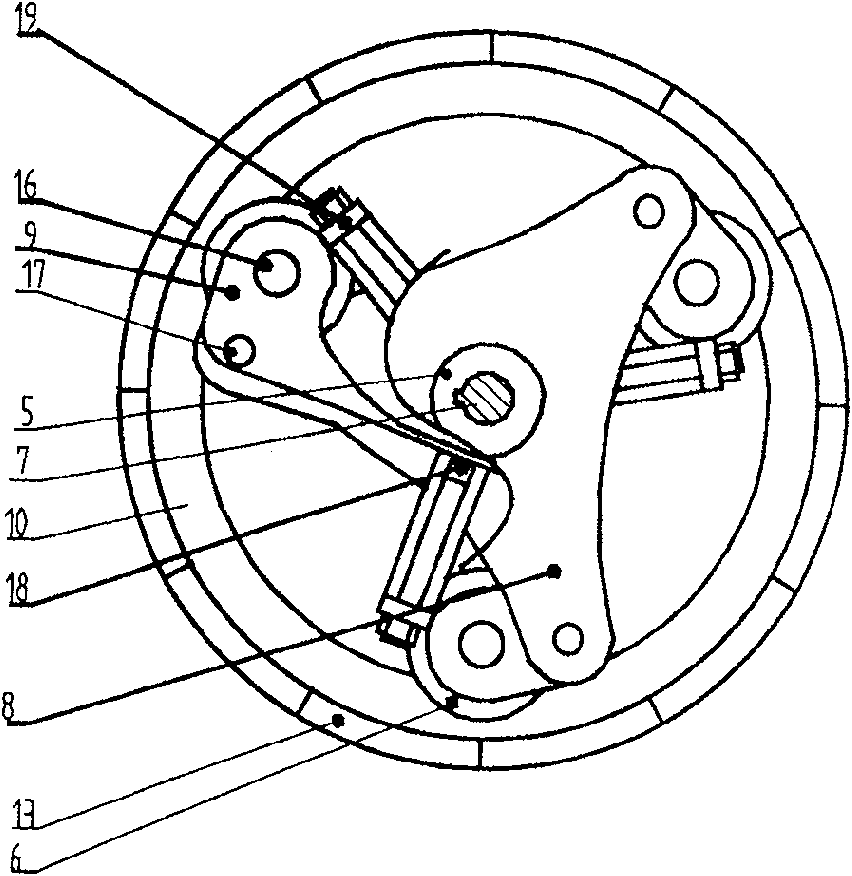

[0020] Embodiment 2: The roller pressure regulator is a hydraulic device, and the hydraulic device 19 is a hydraulic rod. Others are the same as embodiment 1, omitted.

Embodiment 3

[0021] Embodiment 3: The roller pressure regulator is a spring device, the spring device has a spring and a sleeve, and the spring is located inside the sleeve. Others are the same as in the embodiment, omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com