Fully automatic pulverized coal flow rate regulating valve installed on the pulverized pipeline of pulverizing system

A pulverizing system, flow rate adjustment technology, applied in the direction of sliding valve, lift valve, valve details, etc., can solve the problem of coal powder flow rate deviation, etc., to achieve the effect of stable adjustment process, good adjustment performance and linear characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

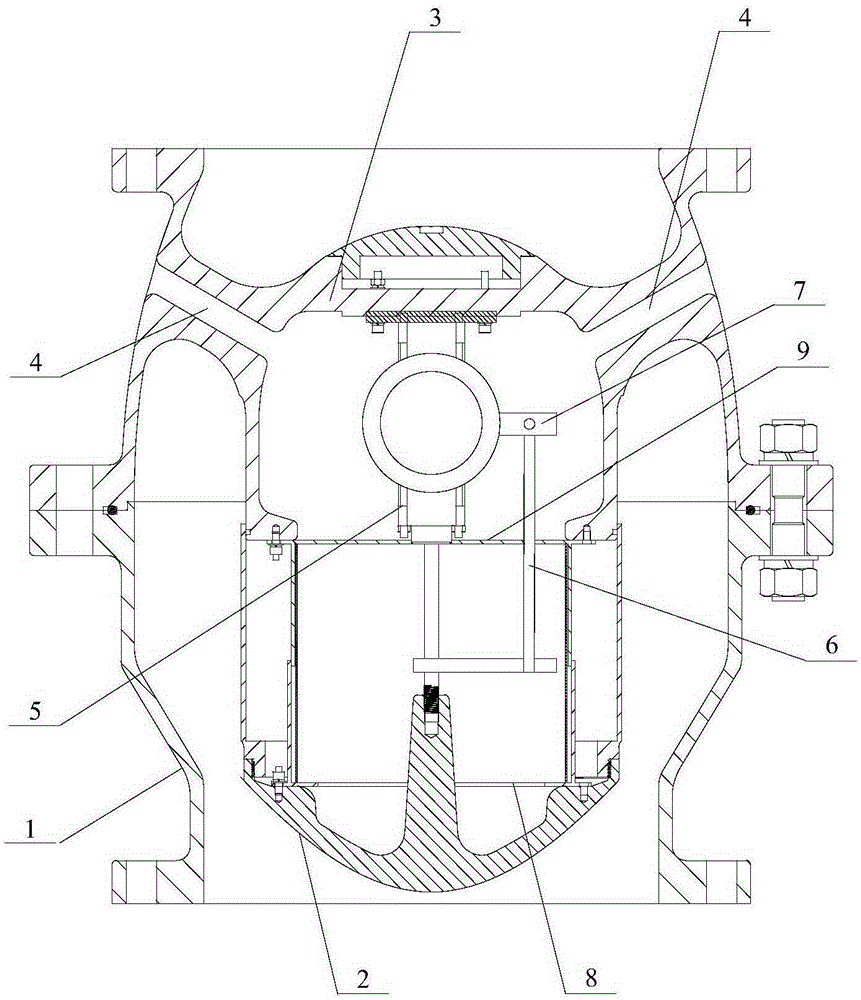

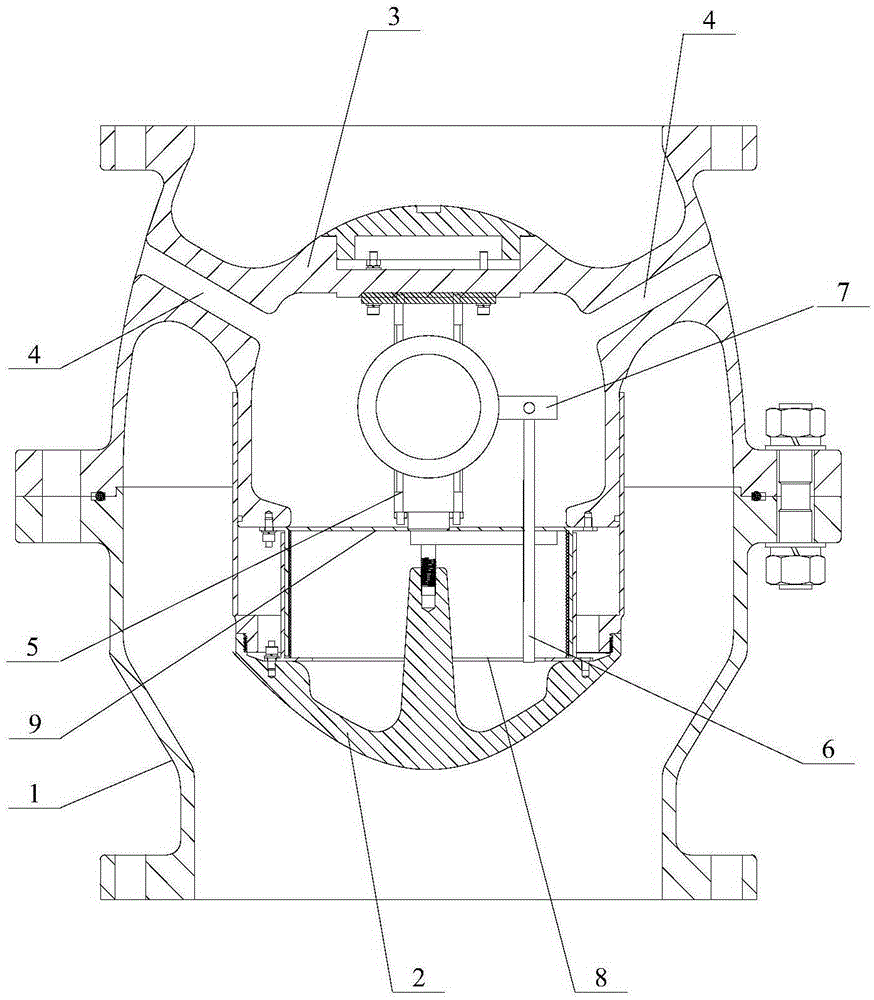

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] Such as figure 1 and figure 2 As shown, the present invention provides a fully automatic pulverized coal flow rate regulating valve installed on the pulverized pipeline of the pulverizing system, including a valve body 1 and a valve core arranged in the valve body 1 . The spool includes upper and lower halves 3, 2, a driving device, a detection device and an inner sealing device. The upper and lower ends of the valve body 1 are provided with connecting flanges, and the valve body 1 is composed of upper and lower parts, which are connected by bolts for easy disassembly and replacement of various parts in the valve core.

[0030] Among them, the upper half body 3 is in the shape of a sleeve with a closed upper end, and the outer wall of the upper half body 3 is fixed on the inner wall of the valve body 1 by a plurality of brackets 4 evenly distributed along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com